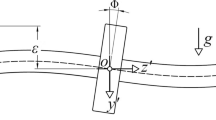

The possible causes of residual deflections in seamless forged rotors are examined. It is shown that measures to eliminate a residual deflection must take its cause into account. A method for correction of rotors proposed by the Leningrad Metal Factory (LMZ), which involves mounting special systems of balanced and “antibalancing” loads on a bent rotor, is analyzed. Calculations show that even the elastic stresses owing to operation of a flexible rotor beyond its critical rotation frequency and, as a rule, exceeding those stresses which the authors of this method propose creating, do not result in correction of a bent rotor.

Similar content being viewed by others

References

V. A. Molochek, Repair of Steam Turbines [in Russian], Énergiya, Moscow (1968).

A. G. Kostyuk, Dynamics and Durability of Turbine Machinery: A Textbook for Universities [in Russian], Izd. MÉI, Moscow (2000).

I. A. Kovalev, L. A. Khomenok, and D. V. El’kin, “The problem of steam turbine rotor bending and ways of solving it,” Tyazh. Mashinostr., No. 10 (2002).

I. A. Kovalev, L. A. Khomenok, and D. V. El’kin, “The problem of steam turbine rotor bending and ways of solving it,” Tyazh. Mashinostr., No. 2 (2003).

A. G. Kostyuk and A. D. Trukhnii, “Durability of seamless forged rotors for 200, 300, and 800 MW turbines manufactured by LMZ under prolonged static load,” Teploénergetika, No. 10 (2004).

M. I. Shklyarov, N. P. Sukhanov, N. P. Egorov, et al. (eds.), Experience in Recovering the Workability of Rotors with Residual Bending. Problems of Vibration, Vibration Adjustment, Vibration Monitoring, and Diagnostics of Equipment for Electric Power Stations [in Russian], Izd. VTI, Moscow (2005).

M. I. Shklyarov, N. P. Sukhanov, N. S. Lebed’ko, et al., “Experience in recovering the workability of rotors with residual bending,” Élektr. Stantsii, No. 10 (2005).

M. I. Shklyarov, Development and Introduction of Methods for Enhancing the Dynamic Reliability and Reducing Vibration in Turbine Assemblies in the Design, Finishing, and Operation Stages. Author’s Abstract of Candidate’s Thesis [in Russian], St. Petersburg (2006).

RF Pat. No. 2079671, M. I. Shklyarov, V. G. Kubarev, and N. N. Shilovich, “A method for correction of steam and gas turbine rotors.”

M. I. Shklyarov, O. A. Zlobin, N. P. Sukhanov, et al., “Engineering diagnostics and vibration adjustment of turbine assemblies,” Élektr. Stantsii, No. 8 (2006).

A. D. Trukhnii, D. D. Korzh, and A. I. Lebedeva, “Generalized fatigue characteristics of R2MA rotor steel for use in engineering diagnostic systems for determining service life,” Teploénergetika, No. 6 (2003).

V. F. Rezinskikh, V. I. Gladshtein, and G. D. Avrutskii, Increasing the Service Life of Long-Running Steam Turbines [in Russian], Izd. MÉI, Moscow (2007).

V. F. Rezinskikh and V. I. Gladshtein, “Service life and reliability of metal in steam turbines for thermal power stations,” Teploénergetika, No. 4 (2004).

Author information

Authors and Affiliations

Additional information

Translated from Élektricheskie Stantsii, January 2009, No. 1, pp. 10–15.

Rights and permissions

About this article

Cite this article

Ur’ev, E.V., Kistoichev, A.V. & Oleinikov, A.V. Correction of rotors by systems of balanced loads. Power Technol Eng 43, 103–107 (2009). https://doi.org/10.1007/s10749-009-0082-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10749-009-0082-7