Abstract

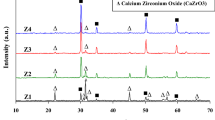

Two methods of incorporating Al2O3 inclusions into a polycrystalline matrix of tetragonal zirconia stabilized with yttria (3Y-TZP) were used, and their influence on the microstructure and properties of TZP/Al2O3 composites has been studied. The first method consisted in the physical mixing of the component powders by means of intensive milling. The second method utilized the possibilities of the coprecipitation method of chemically homogeneous deposits followed by their calcination. An aqueous solution of zirconium, yttrium, and aluminum salts was used. Green compacts were shaped by cold isostatic pressing under a pressure of 300 MPa, and then they were sintered under no pressure for 2 h at 1500–1650°C in air. The powders were also consolidated using hot pressing under 25 MPa in argon and under the same heating cycle as in the case of pressureless sintering. The composites studied contained from 0 to 20 vol % of alumina inclusions, whose sizes depended on the powder preparation method. The morphology and phase composition of the powders and the microstructure of the green compacts and sintered materials were characterized. Bending strength, fracture toughness, and wear were measured. The coprecipitation method enabled us to produce composites that contained nanosize alumina inclusions. The inclusions derived from this method were much smaller than those derived from the physical mixing method (d 50 = 0.21 ± 0.01 and 0.32 ± 0.2 µm, respectively). The reduction in the alumina inclusion size nearly to the nanometer level did not increase the fracture strength and fracture toughness of the composites. The density of the composites and the size of microstructural flaws were the critical factors controlling the fracture strength. The highest strength value, namely, 1.7 ± 0.2 GPa, was measured for the TZP containing 5 vol % of alumina particles incorporated by means of the physical mixing process. The 20 vol % content of alumina particles increased the wear resistance of the 3Y-TZP materials by 51 and 41% for the physical and chemical methods of inclusion incorporation, respectively.

Similar content being viewed by others

REFERENCES

Lee, W.E. and Rainforth, W.M., Ceramics Microstructures-Property Control by Processing, London: Chapman & Hall, 1994, chapter 9.1.1.

Niihara, K.A., Fracture Mechanics Analysis of Indentation Induced Palmqvist Crack in Ceramics, J. Mater. Sci. Lett., 1983, vol. 2, pp. 221–223.

Rejendran, S., Rossell, H.J., and Sanders, J.V., Preparation and Characterization of Precursors Powders for Yttria-Doped Tetragonal Zirconia Polycrystals (Y-TZP) and Y-TZP/Al2O3 Composites, J. Mater. Sci., 1989, vol. 24, pp. 1195–1202.

Der Exter, P., Winnubst, A.J.A., and Burggraaf, A.J., The Preparation and Characterization of Y-TZP/20 vol % Al2O3, J. Eur. Ceram. Soc., 1993, vol. 11, pp. 497–507.

Shi, J.L., Li, B.S., Ruan, M.L., and Yen, T.S., Processing of Nano-Y-TZP/Al2O3 Composites: I. Preparation and Characterization of Nano-Y-TZP/Al2O3 Composite Powders, J. Eur. Ceram. Soc., 1995, vol. 15, pp. 959–965.

Mecartney, M.L., Influence of an Amorphous Second Phase on the Properties of Yttria-Stabilized Tetragonal Zirconia Polycrystals (Y-TZP), J. Am. Ceram. Soc., 1987, vol. 70, pp. 54–58.

Lawn, B., Fracture of Brittle Solids, Cambridge (UK), 1993.

Lange, F.F., Processing-Related Fracture Origins: I. Observations in Sintered and Isostatically Hot-Pressed Al2O3/ZrO2 Composites, J. Am. Ceram. Soc., 1983, vol. 66, no.6, pp. 396–398.

Tsukuma, K., Ueda, K., and Shimads, M., Strength and Fracture Toughness of Isostatically Hot-Pressed Composites of Al2O3 and Y2O3-Partially-Stabilized ZrO2, J.Am. Ceram. Soc., 1982, vol. 68, no.1.

Fukuhara, M., Properties of (Y)ZrO2-Al2O3 and (Y)ZrO2-Al2O3-(Ti or Si)C Composites, J. Am. Ceram. Soc., 1989, vol. 72, pp. 236–242.

Author information

Authors and Affiliations

Additional information

Original English Text Copyright © 2005 by Fizika i Khimiya Stekla, W. Pyda, Brzezinska-Miecznik, Bucko, Pedzich, A. Pyda.

This article was submitted by the authors in English.

Rights and permissions

About this article

Cite this article

Pyda, W., Brzezinska-Miecznik, J., Bucko, M.M. et al. Composites Derived from Zirconia Nanopowders Stabilized with Yttria and Containing Alumina Particles Incorporated Physically or Chemically. Glass Phys Chem 31, 554–561 (2005). https://doi.org/10.1007/s10720-005-0098-5

Issue Date:

DOI: https://doi.org/10.1007/s10720-005-0098-5