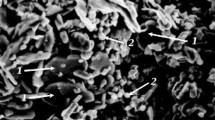

The results of investigations on the development of compositions of ceramic bodies for obtaining effective heat-insulating materials and products are presented. The materials were obtained by pressing with the use of kaolin clays differing in plasticity as well as fire-resistance. A porous structure of the material was created by introducing a porous filler in the form of swollen hydromica, developed according to the ferruginous hydrophlogopite type, in an amount of 50 wt.%. The apparent density and the mechanical strength were investigated as functions of the press-pressure and shrinkage on firing. The use of expanded hydromica made it possible to obtain products with density up to 1000 kg/m3 while thermomechanical properties retention up to 1050°C.

Similar content being viewed by others

References

Ya. Guzman, “Ñertain principles of formation of porous ceramic structures, properties, and applications (A Review),” Glass Ceram., 60(9 – 10), 280 – 283 (2003).

Chaouki Sadik, Abderrahman Albizane, and Iz-Eddine El Amrani, “Production of porous firebrick from mixtures of clay and recycled refractory waste with expanded perlite addition,” J. Mater. Environ. Sci., No. 4(6), 981 – 986 (2013).

H. Aripina, L. Lestaria, L. Agusua, et. al., “Preparation of Porous Ceramic with Controllable Additive and Firing Temperature,” Adv. Mater. Res., 277, 151 – 158 (2011). DOI: https://doi.org/10.4028/www.scientific.net/AMR.277.15

D. S. Smith, A. Alzina, J. Bourret, et al., “Thermal conductivity of porous materials,” J. Mater. Res., 28(17), 2260 – 2272 (2013). DOI: https://doi.org/10.1557/jmr.2013.179; URL: https://www.cambridge.org/core/journals/journal-of-materials-research/issue/D7F1FF31D001ECB09F7EFCF7E4EEE7A0

V. T. Shmuradko, F. I. Panteleenko, O. P. Reut, et al., “Formation of the composition, structure, and properties of heat-insulating fire and heat-protective materials based on vermiculite for industrial power engineering,” Novye Ogneupory, No. 8, 39 – 44 (2012).

V. E. Peletskii and B. A. Shur, “Experimental study of the thermal conductivity of heat-shielding materials based on expanded vermiculite,” Novye Ogneupory, No. 11, 41 – 43 (2007).

S. A. Suvorov and V. V. Skurikhin, “Vermiculite is a promising material for the production of high-temperature thermal insulation,” No. 2, 44 – 52 (2003).

Jiaqi Sun, Yan Yang, Jannick Ingrin, Zhongping Wang, et. al., “Impact of fluorine on the thermal stability of phlogopite,” Am. Mineralogist, 107(5), 815 – 825 (2022). DOI: https://doi.org/10.2138/am-2022-8051/

I. N. Khaidarov and R. I. Ismailov, “Research of features and compositions of vermiculite for use as suspension fire retardant for textile materials,” Tech. Sci. Innov., No. 2, Art. 9, 64 – 69 (2020). URL: https://uzjournals.edu.uz/btstu/vol2020/iss2/9

E. L. Popov, Kh. Akhmedov, and G. R. Khabibullaeva, “Results of technological studies of two samples of vermiculite ore from the Tebinbulak deposit,” Gorny Vest. Uzbekistana, No. 4(43), 84 – 87 (2010). URL: http://gorniyvestnik.uz/assets/uploads/ pdf/2010-oktyabrdekabr.pdf

M. Kh. Rumi, E. M. Urazaeva, Sh. R. Nurmatov, et al., “Mineralogical features of expanding vermiculite ores,” Steklo Keram., 25(9), 55 – 65 (2022).

M. A. Ivanov, V. I. Pak, A. Yu. Nalivaiko, et al., “Prospects for the use of Russian high-silicon aluminum-containing raw materials in alumina production,” Izv. Tomsk. Politekh Univ., Inzhiniring Georesursov, 330(3), 93 – 102 (2019).

F. Bergaya, P. Dion, J. F. Alcover, et. al., “TEM study of kaolinite thermal decomposition by controlled-rate thermal analysis,” J. Mater. Sci., 31(19), 5069 – 5075 (1996).

V. A. Drits and A. G. Kossovskaya, Clay Minerals: Micas, Chlorites [in Russian], Nauka, Moscow (1991).

G. L. Lecomte, J. P. Bonnet, and P. Blanchart, “A study of the influence of muscovite on the thermal transformations of kaolinite from room temperature up to 1100°C,” J. Mater. Sci., 42(20), 8745 – 8752 (2007). DOI: https://doi.org/10.1007/s10853-006-0192-7

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Steklo i Keramika, No. 2, pp. 9 – 18, February, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rumi, M.K., Urazaeva, E.M., Irmatova, S.K. et al. Sintering Characteristics and Thermal Properties of Porous Ceramic Based on Hydrophlogopite and Refractory Clays. Glass Ceram 80, 45–51 (2023). https://doi.org/10.1007/s10717-023-00555-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10717-023-00555-z