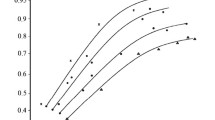

The heat transfer coefficients and thermal conductivity of glass coatings on heat exchange tubes were investigated. A formula is obtained for determining the maximum thermal conductivity of a glass coating. It was found that during long-time operation of a heat exchanger the heat transfer coefficient of the glass coating on the pipe is independent of the cleanliness of the glass surface from the time of operation. However, in brass or copper pipes, over time the heat transfer coefficient drops sharply due to the formation of a strong layer of scale and corrosion products. A formula is obtained for calculating the maximum value of the heat transfer coefficient of glass coatings on pipes.

Similar content being viewed by others

References

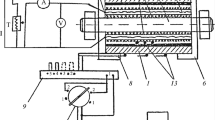

V. A. Permyakov, K. V. Permyakov, V. M. Borovkov, and S. M. Koshelev, “Home-grown next-generation shell-and-tube heaters for process heating systems,” Prom. Énergetika, No. 11, 22 – 30 (2004).

N. Yu. Ibragimov, “Change of the thermal conductivity of a glass coating on flow of seawater in glazed brass tubes,” Izv. Vyssh. Ucheb. Zaved., Neft’ i Gas, No. 1 – 2, 48 – 50 (1998).

D. M. Rudnov, “Testing of physical methods of preventing scale formation,” Oborud. Tekhnol. Neftegaz. Kompleksa, No. 6, 26 – 30 (2012).

Yu. V. Alekseev, “Selecting corrosion-resistant tubes for the conditions of a deposit,” Inzh. Praktika, No. 1. 64 – 71 (2012).

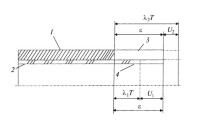

N. Yu. Ibragimov, “Temperature regime for glazing of heat exchange tubes,” Izv. Vysh. Ucheb. Zaved., Énergetika, No. 5 – 6. 77 – 80 (1997).

A. V. Petzold and G. A. Peshman, Enamel and Enamelling [in Russian], Metallurgiya, Moscow (1990).

OST 26-01-1255–83. Glass-Enamel and Glass-Ceramic Coatings. Methods of Testing for Corrosion Resistance in acids and Alkalis [in Russian], Moscow (1995), pp. 87 – 89.

N. Yu. Ibragimov, “Temperature regime on applying a glass coating to the inner surface of a heat exchange tube,” Glass Ceram., 76(5 – 6), 225 – 227 (2019).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Steklo i Keramika, No. 11, pp. 25 – 29, November, 2022.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ibragimov, N.Y. Thermal Processes in Glazed Tubes of a Heat Exchanger. Glass Ceram 79, 453–456 (2023). https://doi.org/10.1007/s10717-023-00531-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10717-023-00531-7