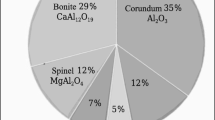

Parts with high physicotechnical and chemical characteristics at firing temperature 1300°C can be obtained by introducing in amount 40% into the ceramic body nanotechnical high-alumina raw material from calcined alkaline-etching sludge. Nanotechnogenic raw materials afford higher surface energy, which is the source of the sintering process. Investigations showed that in compositions not containing high-alumina raw material — calcined sludge from alkaline-etching — mainly mullite is formed and is responsible for the operational properties of ceramic parts. X-ray diffractometric analysis showed that the introduction of calcined alkaline sludge into the compositions of ceramic bodies affords the formation of corundum.

Similar content being viewed by others

References

E. S. Abdrakhimova and V. Z. Abdrakhimov, Physicochemical Processes in the Firing of Acid-Resistant Materials [in Russian], Nedra, St Petersburg (2003).

V. Z. Abdrakhimov, A. K. Kairakbaev, and E. S. Abdrakhimova, Environmental and Practical Aspects of Non-ferrous Metallurgy Waste Recycling in the Production of Acid-resistant Materials and Floor Tiles [in Russian], Baishev Aktobe University, Aktobe (2018).

D. S. Tyul’kin and P. M. Pletnev, “Characteristics of homegrown raw materials for the production of heat-resistant high-temperature corundum-mullite refractories,” in: Int. Conf. STROYSIB 2016: Resources and Resource-Saving Technologies in Materials Science [in Russian], Novosibirsk (2016), pp. 204 – 209.

D. A. Beglov, Ya. N. Pitak, I. A. Ostapenko, and O. M. Andrusenko, “Study of the influence of batch composition on the properties of dense fireclay refractories,” Vost.-Evrop. Zh. Peredovykh Tekhn., No. 6, 34 – 38 (2011).

A. S. Ryshchenko, T. D. Ryshchenko, and Ya. N. Pitak, “Mullite-corundum refractories based on synthesized high-alumina chamotte,” Vost.-Evrop. Zh. Peredovykh Tekhn., No. 6, 64 – 68 (2011).

A. I. Khlystov, S. V. Sokolova, and A. V. Vlasov, “Raising the efficiency of heat-resistant composites through the use of chemical binders,” Stroit. Mater. Oborud. Tekhn. XXI Veka, No. 9, 38 – 42 (2012).

G. G. Gaprindashvili, M. K. Kekelidze, and L. K. Tedeishvili, “Acid resistant ceramic materials produced using industrial waste products,” Glass Ceram., 45, 34 – 38 (1988) [Steko Keram., No. 1, 21 – 23 (1988)].

R. F. Yulmetova, Chemical Thermodynamics [in Russian], St. Petersburg (2015).

A. V. Artemov, Physical Chemistry [in Russian], Academia, Moscow (2019).

V. Z. Abdrakhimov, A. K. Kairakbaev, and E. S. Abdrakhimova, Environmental and Practical Aspects of the Non-ferrous Metallurgy Waste Recycling in the Production of Acid-resistant Materials and Tiles for Floors [in Russian], Baishev Aktobe University, Aktobe (2018).

D. P. Zarubin, Physical Chemistry [in Russian], Infra, Moscow (2018).

A. A. Popova and T. B. Popova, Physical Chemistry [in Russian], Lan’, St. Petersburg (2015).

P. Atkins, Physical Chemistry, Pt. 1. Equilibrium Thermodynamics [Russian translation], Mir, Moscow (2007).

S. M. Logvinkov, N. A. Ostapenko, G. N. Shabanova, et al., “Mullite and a compound of the sillimanite group in the technology of ceramics and refractories,” Vest. Nauch. Tekh. Univ. Kharkov. Politekh., No. 49, 39 – 48 (2017).

I. D. Kashcheev, K. K. Strelkov, and P. S. Mamykin, Chemical Technology of Refractories [in Russian], Intermet Inzhiniring, Moscow (2007).

P. M. Pletnev, V. M. Pogrebenkov, V. I. Vereshchagin, and D. S. Tyul’kin, “Mullite-corundum materials based on mullite binder resistant to high-temperature deformations,” Novye Ogneupory, No. 11, 36 – 43 (2017).

E. M. Nikiforova, R. G. Eromasov, N. S. Simonova, et al., “Phase transformations in the system of siliceous rocks – mineralizer,” Sovr. Probl. Nauki Obraz., No. 2 (2012); URL: http://scienceeducation.ru/ru/article/view?id=5741 (date of access: 06.27.2021).

A. S. Tolkacheva and I. A. Pavlova, General Questions of the Technology of Fine Ceramics [in Russian], Ural University, Ekaterinburg (2018).

E. S. Abdrakhimova and V. Z. Abdrakhimov, Fundamentals of Technical Ceramics [in Russian], East Kazakhstan State Technical University, Ust’-Kamenogorsk (2001).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Steklo i Keramika, No. 9, pp. 33 – 39, September, 2021.

Rights and permissions

About this article

Cite this article

Abdrakhimova, E.S. Influence of High-Alumina Alkaline-Etching Sludge on the Technical Indicators and Phase Composition of Acid-Resistant Materials. Glass Ceram 78, 369–373 (2022). https://doi.org/10.1007/s10717-022-00413-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10717-022-00413-4