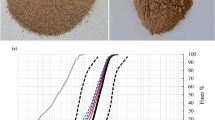

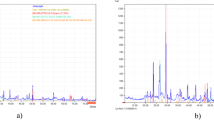

Ceramic bricks based on low-melting clay and ferro-dust from self-disintegrating, low-carbon, ferrochrome slags, graded from M100 to M175, respectively, were obtained in the temperature range 950 – 1100°C. The highest grades are in bricks fired at the temperatures 1050 and 1100°C, respectively, M150 and M175, which can be used as earthquake-resistant. Studies have shown that hematite, wollastonite, diopside and a liquid phase appear at brick firing temperature 950°C. Raising the firing temperature to 1000°C contributes to the appearance of anorthite and cristobalite. Raising the firing temperature to 1050°C does not bring about any special changes, except for an increase in the content of cristobalite and anorthite and a decrease in the content of feldspar. Subsequent raising of the firing temperature to 1100°C results in higher content of anorthite, diopside and cristobalite. The physicomechanical indicators increase due to the formation of anorthite and diopside in the samples.

Similar content being viewed by others

References

G. T. Nurmadieva and B. A. Zhetpisbaev, “Influence of the ecosystem on human health in industrialized regions of Kazakhstan: Literature review,” Nauka i Zdravookhranenie, No. 4, 107 – 132 (2018).

G. Zh. Seitkasymova, “Assessment of the quality of the natural system ‘surface water – soil’ for the example of an Irgiz village in the Aktobe region,” Gigiena Truda Med. Ékol., No. 1, 77 – 80 (2016).

National report on the state of the environment and the use of natural resources of the Republic of Kazakhstan for 2018; URL: http://ecogos-fond.kz/orhusskaja-konvencija/dostupk-jekologicheskoj-informacii/jekologijaly-zha-daj/r-orsha-anortany-zhaj-k-ji-turaly-lttybajandamalar/

A. Moutsatsou, M. Gregou, D. Matsas, and V. Protonotarios, “Washing as a remediation technology applicable in soils heavily polluted by mining-metallurgical activities,” Chemosphere, 63(10), 1632 – 1640 (2006).

J. Paldyna, B. Krasnodebska-Ostrega, K. Kregielewska, and J. Kowalska, “The assessment of environmental pollution caused by mining and metallurgy wastes from highly polluted post-industrial regions in Southern Poland,” Environmental Earth Sci., 68(2), 439 – 450 (2013).

B. Dhal, H. N. Thatoi, N. N. Das, and B. D. Pandey, “Chemical and microbial remediation of hexavalent chromium from contaminated soil and mining/metallurgical solid waste: a review,” J. Hazardous Mater., 250 – 251, 272 – 291 (2013).

A. Vanìk, Z. Grösslová,M. Mihaljeviè, and V. Ettler, “Thallium isotopes in metallurgical wastes/contaminated soils: A novel tool to trace metal source and behavior,” J. Hazardous Mater., 343, 78 – 85 (2018).

A. Vanìk, V. Chrastný, M. Komárek, et al., “Geochemical position of thallium in soils from a smelter-impacted area,” J. Geochem. Explor., 124, 176 – 182 (2013).

Decree of the President of the Republic of Kazakhstan dated May 30, 2013 No. 577 ‘On the Concept for the transition of the Republic of Kazakhstan to a green economy’; URL: https://strategy2050.kz/static/files/Concept_Rus.pdf

P. Niemelä and M. Kauppi, “Production, characteristics and use of ferrochromium slags,” INFACON, 11, 171 – 179 (2007).

S. K. Nath, “Geopolymerization behavior of ferrochrome slag and fly ash blends,” Constr. Build. Mater., 181, 487 – 494 (2018).

P. K. Acharya and S. K. Patro, “Utilization of ferrochrome wastes such as ferrochrome ash and ferrochrome slag in concrete manufacturing,” Waste Manag. Res., 34(8), 764 – 774 (2016).

N. Sahu, A. Biswas, and G. U. Kapure, “A short review on utilization of ferrochromium slag,” Mineral Proc. Extract. Metall. Rev., 37(4), 211 – 219 (2016).

M. Sütçü, O. Gencel, E. Erdo?mu?, and V. Koc, “Properties of bricks with waste ferrochromium slag and zeolite,” J. Cleaner Prod., 59, 111 – 119 (2013).

O. V. Zayakin and I. N. Kel, “Promising directions for the stabilization of ferroalloy production slags,” Mater. Sci. Forum, Trans. Tech. Publ. Ltd, 946, 401 – 405 (2019).

T. Bazhirov, N. Bazhirov, and K. Bazhirova, “Study of slags from ferrochrome production as components for heat-resistant materials,” in: Industrial Technologies and Engineering (ICITE2018): 5th International Scientific and Practical Conference, Shymkent, November 28, 2018, Shymkent (2018), pp. 70 – 74.

I. D. Kascheev, V. I. Zhuchkov, and O. V. Zayakin, “Forming and Utilizing Ferrochromium Production Waste,” in: Intern. Rus. Conf. on Materials Science and Metallurgical Technology, RusMetalCon 2019, Chelyabinsk, Russia, 1 – 4 Oct. 2019, Mater. Sci. Forum, Trans. Tech. Publ. Ltd. (2020), Vol. 5, pp. 492 – 497.

A. K. Kairakbaev and V. Z. Abdrakhimov, Composition for the Production of Porous Filler, Pat. 34002 Republic of Kazakhstan, IPC S 04 B 14/24; applicant and patent holder Technopark Zerek Institutions Baishev Aktobe University LLP 2018/0397.1; declared 06/11/2018; date of issue 06.11.2019.

A. K. Kairakbaev and V. Z. Abdrakhimov, Ceramic Mass for Brick Making, Pat. 34005 Republic of Kazakhstan, IPC S 04 B 33/132; applicant and patent holder Technopark Zerek Institutions Baishev Aktobe University LLP 2018 0419.1; declared 06/11/2018; date of issue 06.11.2019.

E. Matinde, G. S. Simate, and S. Ndlovu, “Mining and metallurgical wastes: a review of recycling and re-use practices,” J. Southern African Inst. Mining Metall., 118(8), 825 – 844 (2018).

T. V. Safronova, V. I. Vereshchagin, and E. V. Bayandina, “Building ceramics based on compositions of low and medium plastic clay and diopside raw materials,” Vest. Tomsk. Gos. Arkh.-Stroit. Univ., No. 2, 154 – 162 (2012).

A. K. Kairakbaev, E. S. Abdrakhimova, and V. Z. Abdrakhimov, “Innovative approaches to using Kazakhstan’s industrial ferrous and nonferrous tailings in the production of ceramic materials,” Mater. Sci. Forum. Trans. Tech. Publ. Ltd, Switzerland, 989, 54 – 61 (2020).

M. K. Imangazin, E. S. Abdrakhimov, V. Z. Abdrakhimov, and A. K, Kairakbaev, “ Innovative directions for the use of ferrous- metallurgy wastes in the production of ceramic brick,” Metallurg, No. 2, 22 – 25 (2017).

J. Yu. Roshchupkina, E. S. Abdrakhimova, A. K. Kairakbaev, et al. “Innovative technology developments aimed at structural-chemical modification of lining materials based on nonferrous metallurgy waste and phosphate binders,” Refract. Industr. Ceram., 56(4), 398 – 401 (2015).

This work was performed as part of a scientific and technical project approved for grant funding for 2018 – 2020 by the National Scientific Council of the Republic of Kazakhstan in the direction of science ‘Rational use of natural resources, including water resources, geology, processing, new materials and technologies, safe products and structures,’ Grant Agreement No. 177, dated March 15, 2018, IRN 05131501.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Steklo i Keramika, No. 12, pp. 45 – 50, December, 2020.

Rights and permissions

About this article

Cite this article

Kairakbaev, A.K., Abdrakhimov, V.Z. & Abdrakhimova, E.S. Phase Composition and Physico-Mechanical Properties at Different Firing Temperatures of Ceramic Earthquake-Resistant Bricks with the Use of Ferro-Dust. Glass Ceram 77, 478–482 (2021). https://doi.org/10.1007/s10717-021-00336-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10717-021-00336-6