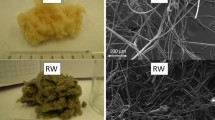

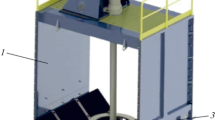

A new technology for forming multilayer mineral-wool mats by zig-zag pendulum layering of the primary mineral mat is described. It consists in forming variable-height loops in the primary mineral-wool mat in order to equalize the feed rate of the primary mineral-wool mat to the pendulum layering device and the circular velocity of the pendulum at the point of egress from it of the primary mineral-wool mat over the entire extent of the zig-zag layering pattern of the primary mat. Analytical formulas are given for calculating the parameters of the technology implementing the new method of zig-zag pendulum layering of mineral-wool mats.

Similar content being viewed by others

References

G. I. Koval and T. G. Karimova, “Parameters and conditions determining the qualitative characteristics of mineral-wool products,” Vest. Yuzh. Ural. Gos. Univ., Ser. Stroit-vo Arkhitekt., 17(3), 58 – 64 (2017).

G. A. Lebedeva, “Study of the technological properties of Karelian rocks as raw material for production of mineral wool,” Steklo Keram., No. 10, 26 – 28 (2007); G. A. Lebedeva, “Study of the technological properties of Karelian rocks as raw material for production of mineral wool,” Glass Ceram., 64(9 – 10), 360 – 362 (2007).

N. K. Skripnikova, A. A. Nikiforov, and O. G. Volokitin, “Electroplasma facility for obtaining mineral fiber from refractory silicate-containing materials,” Steklo Keram., No. 11, 14 – 16 (2008); N. K. Skripnikova, A. A. Nikiforov, and O. G. Volokitin, “Electroplasma facility for obtaining mineral fiber from refractory silicate-containing materials,” Glass Ceram., 65(11 – 12), 393 – 395 (2008).

A. G. Novitskii and M. V. Efremov, “Some aspects of the manufacturing process for obtaining continuous basalt fiber,” Steklo Keram., No. 11, 30 – 34 (2010); A. G. Novitskii and M. V. Efremov, “Some aspects of the manufacturing process for obtaining continuous basalt fiber,” Glass Ceram., 67(11 – 12) [Article: 361] (2010).

O. S. Tatarintseva, N. N. Khodakova, and T. K. Uglova, “Dependence of the viscosity of basalt melts on the chemical composition of the initial mineral material,” Steklo Keram., No. 10, – 14 (2011); O. S. Tatarintseva, N. N. Khodakova, and T. K. Uglova, “Dependence of the viscosity of basalt melts on the chemical composition of the initial mineral material,” Glass Ceram., 68(9 – 10), 323 – 326 (2011).

G. G. Volokitin, N. K. Skripnikova, O. G. Volokitin, and S. Volland, “Technology for producing mineral fibers by recycling ash-sludge and oil-shale wastes,” Steklo Keram., No. 8, 3 – 5 (2011); G. G. Volokitin, N. K. Skripnikova, O. G. Volokitin, and S. Volland, “Technology for producing mineral fibers by recycling ash-sludge and oil-shale wastes,” Glass Ceram., 68(7 – 8), 239 – 241 (2011).

A. G. Novitskii and M. V. Efremov, “Technological aspects of the suitability of rocks from different deposits for the production of continuous basalt fiber,” Steklo Keram., No. 12, 22 – 28 (2012); A. G. Novitskii and M. V. Efremov, “Technological aspects of the suitability of rocks from different deposits for the production of continuous basalt fiber,” Glass Ceram., 69(11 – 12), 409 – 412 (2012).

A. V. Kochergin, N. V. Granovskaya, D. V. Kochergin, et al., “Ways to supply gabbro-basalt raw materials to mineral fiber producers,” Steklo Keram., No. 12, 17 – 21 (2012); A. V. Kochergin, N. V. Granovskaya, D. V. Kochergin, et al., “Ways to supply gabbro-basalt raw materials to mineral fiber producers,” Glass Ceram., 69(11 – 12), 405 – 408 (2012).

L. I. Khudyakova, S. L. Buyantuev, and O. V. Voiloshnikov, “Mineral fiber obtained using low-temperature plasma,” Steklo Keram., No. 8, 25 – 28 (2013); L. I. Khudyakova, S. L. Buyantuev, and O. V. Voiloshnikov, “Mineral fiber obtained using low-temperature plasma,” Glass Ceram., 70(7 – 8), 297 – 299 (2013).

O. G. Volokitin, G. G. Volokitin, and N. K. Skripnikova, “Mineral fiber production based on ash from the republic of Kazakhstan using low-temperature plasma apparatus,” Steklo Keram., No. 9, 31 – 34 (2013); O. G. Volokitin, G. G. Volokitin, and N. K. Skripnikova, “Mineral fiber production based on ash from the republic of kazakhstan using low-temperature plasma apparatus,” Glass Ceram., 70(9 – 10), 340 – 343 (2013).

Joergen Luns Nerger, Kim Brand, and Ian Cridland, “Method of fabricating solidified bonded fabric from mineral fiber and apparatus for its implementation, RF Pat. No. 2152489, No. 96117383/03,” Byull. Izobr. Polezn. Modeli, No. 19 (2000), appl. January 27, 1995; publ. July 10, 2000.

WO 1988/03509. IPC B65H 45/10. D01G 25/00, D04H 1/70. A Method for Feeding the PrimaryWeb of Mineral-WoolWeb by Means of a Pendulum Conveyor onto a Receiving Conveyor, a Receiving Conveyor, and an Arrangement of Such A, May 19, 1988.

WO 1988/03121. IPC B 65H 45/10, D 01G 25/00, D04H 1/70. A Process ATB Device for Feeding a Thin Binder Impregnated Uncured Primary Web of Mineral Wool onto a Receiving Conveyor, May 05, 1998.

Unkuri Matti and Nurmi Tom, Method for Feeding the Primary Web of a Mineral-Wool Web by Means of a Pendulum Conveyor onto a Receiving Conveyor and an Arrangement of Such a Pendulum Conveyor, US 5007623 A. B65H 45/10, 16.04.1991 (1991).

G. I. Koval and T. G. Karimova, “Method of producing mineral-wool products, RF Pat. 2492044; No. 2012114827,” Byull. Izobr. Polezn. Modeli, No. 10 (2013), appl. April 13, 2012; publ. September 10, 2013.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Steklo i Keramika, No. 3, pp. 35 – 39, March, 2020.

Rights and permissions

About this article

Cite this article

Koval’, G.I., Karimova, T.G. New Technology for Producing Mineral-Wool Products. Glass Ceram 77, 109–112 (2020). https://doi.org/10.1007/s10717-020-00250-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10717-020-00250-3