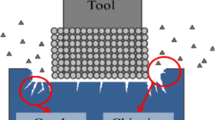

The results of the successful laser drilling of 30 – 200 μm in diameter microholes in glass ranging in thickness from 0.1 to 0.8 mm are reported. High-quality holes together with high process performance are achieved by using in the hole piercing process an immersion cooling liquid in contact with the bottom surface of the glass.

Similar content being viewed by others

References

L. A. Hof and Jana Abou Ziki, Micro-Hole Drilling on Glass Substrates: A Review, Department of Mechanical & Industrial Engineering, Concordia University, Bharti School of Engineering, Laurentian University, Sudbury (2017).

CO2-Laser Drilling of through Glass Vias (TGVs), Fraunhofer Institute for Reliability and Micro-Integration IZM; URL:http:__www.izm.fraunhofer.de (accessed on 7 February 2017).

L. Brusberg, M. Queisser, C. Gentsch, et al., “Advances in CO2-laser drilling of glass substrates,” Phys. Proc., 39 (2012), Fraunhofer Institute for Reliability and Micro-Integration IZM.

D. J. Hwang, T. Y. Choi, and C. P. Grigoropoulos, “Liquid-assisted femtosecond laser drilling of straight and three-dimensional microchannels in glass,” Appl. Phys. A. Mater. Sci. Proc., 79, 605 – 612 (2004).

M. Castillejo, P. M. Ossi, and L. Zhigilei, Lasers in Materials Science, Springer, Cham (2014).

E. D. Vaks, M. N. Milen’kii, and L. G. Saprykin, Practice of Precision Laser Processing [in Russian], Tekhnosfera, Moscow (2013).

A. Kruusing, Underwater and Water-Assisted Laser Processing. Pt 2. Etching, Cutting and Rarely Used Method, Tallinn Technical University, Tallinn (2002).

Reo Murakami, Hiroyuki Nakagawa, and Shigeki, “Water-assisted laser drilling for miniature internal thread in glass and evaluation of its strength,” Matsuo Department of Mechanical Engineering, Shibaura Institute of Technology; J. Laser Micro Nanoeng., 12(3), 203 – 206 (2017).

H. Huang, L. Yang, and J. Liu, “Micro-hole drilling and cutting using femtosecond fiber laser,” Opt. Eng., 5 (2014).

A. A. Aleksandrov and B. A. Grigor’ev, Tables of the Thermophysical Properties of Water and Water Vapor [in Russian], Izd. MEI, Moscow (1999).

L. M. Ozherelkova and E. S. Savin, “Temperature dependence of the nonstationary thermal conductivity of solids,” Ross. Tekh. Zh., 7(2), 49 – 60 (2019).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Steklo i Keramika, No. 2, pp. 3 – 7, February, 2020.

Rights and permissions

About this article

Cite this article

Kondratenko, V.S., Kadomkin, V.V., Hung-Tu, L. et al. Laser Drilling of Microholes in Glass. Glass Ceram 77, 39–42 (2020). https://doi.org/10.1007/s10717-020-00233-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10717-020-00233-4