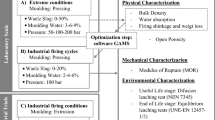

The grain size of ground glass as the main component has a decisive influence on the quality of construction products made from foam-glass concrete. This means that the grain size must be regulated for definite types of products and it must be possible to make in-line adjustments in the comminution of technogenic cullet. To this end an adaptive vibratory mill equipped with an electronic-hydraulic control system for making in-line adjustments in the technological regime of comminution as a function of the initial material and the required grain size of the comminuted glass was developed.

Similar content being viewed by others

References

Waste-free Technologies and the Use of Secondary Products and Wastes in the Building Materials Industry [in Russian], Stroiizdat, Moscow (1985), pp. 38 – 40.

R. G. Melkonyan, E. A. Elchaninov, and V. M. Shek, “Industrial assimilation of wastes from the glass industry,” Gornyi Inform.-Analit. Byull. (MGGU), No. 6, 165 (2004).

B. K. Demidovich, Foam Glass [in Russian], Nauka i tekhnika, Minsk (1975).

B. K. Demidovich, Production and Use of Foam Glass [in Russian], Nauka i tekhnika, Minsk (1972).

A. Ketov, “Peculiar chemical and technological properties of glass cullet as the raw material for foamed insulation,” in: Recycle and Reuse of Waste Materials: International Symposium, Dundee, United Kingdom (2003), pp. 695 – 704.

A. A. Ketov, I. S. Puzanov, and D. V. Saulin, “Experience in foam glass materials production from cullet,” Stroit. Mater., No. 3, 70 – 72 (2007).

Yu. M. Smirnov, B. M. Kenzhin, M. A. Zhurunova, et al., Methodology for Laboratory Testing of Samples of Gas-Glass and Foam-Glass Concrete based on Technogenic Cullet, Sanat, Karaganda (2018).

Weilie Zhou and Zhong Lin Wang (eds.), Scanning Microscopy for Nanotechnology (Techniques and Applications), Springer, NY (2006).

B. M. Kenzhin, T. M. Nurgozhin, Yu. M. Smirnov, and S. T. Ualiev, “Prerequisites for the creation of technologies for the production of building concrete based on foam glass,” Prom-st’ Kazakhstana, No. 1(100), 24 – 26 (2017).

Yu. M. Smirnov, B. M. Kenzhin, V. M. Smirnov, and M. A. Zhurunova, “RK Pat. No. 32897, Adaptive vibratory mill for the production of ultrafine ground cement,” Byull. Izobr. Polezn. Modeli, No. 23 (2018), application No. 2016/0942.1, 10/18/2016; publ. 05/29/2018.

This work was performed as part of the subproject ‘Commercialization of energy-conserving technologies for the production of gas- and foam-glass concretes,’ financed as part of the project ‘Stimulation of productive innovations,’ supported by the World Bank and the government of Kazakhstan. The main results and recommendations may not reflect the official position of the World Bank and the government of Kazakhstan.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Steklo i Keramika, No. 7, pp. 42 – 46, July, 2019.

Rights and permissions

About this article

Cite this article

Smirnov, Y.M., Kenzhin, B.M., Imanov, E.K. et al. Quality Improvement of Construction Products Based on Technogenic Cullet. Glass Ceram 76, 274–277 (2019). https://doi.org/10.1007/s10717-019-00182-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10717-019-00182-7