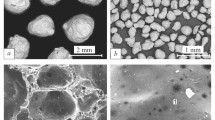

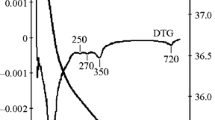

The activity of foam ceramic and foam glass in terms of the silicate-alkali interaction in concrete was investigated. It was found that in the wet environment in concrete the vitrified walls of the pores of the aggregates are chemically active. The transformations of foam ceramic include gelation of the pore walls with formation of an alkaline aluminosilicate gel followed by its crystallization. This binds the active components on such an aggregate in the crystalline phases, which are inert in a moist environment. The final stage of the transformation of the foam glass is noncrystallizing, alkaline, hydrated, silica gel.

Similar content being viewed by others

Notes

Here and below, content by weight, %.

References

A. M. Neville, Properties of Concrete [Russian translation], Stroiizdat, Moscow (1972).

“Standard test method for determination of length change of concrete due to alkali-silica reaction. ASTM C 1293-01,” in: Annual Book of ASTM Standards, V. 04.02, American Society for Testing and Materials, Philadelphia (2002).

F. M. Ivanov, G. V. Lyubarskaya, and N. K. Rozental, “Interaction of the aggregates of concrete with the alkali of cement and additives,” Beton i Zhelezobeton, No. 1, 15 – 18 (1995).

Ñ. Meyer, L. Egosi, and Ñ. Andela, “Concrete with waste glass as aggregate,” in: Recycling and Reuse of Glass Cullet: Proceedings of International Symposium, Dundee, UK, 19 – 20 March 2001, Dundee (2001), pp. 179 – 187.

E. A. Byars, H. Zhu, and Ñ. Meyer, “Use of glass for construction products: legislative and technical issues,” in: Sustainable Waste Management: Proceedings of the International Symposium, Dundee, UK, 9 – 11 September 2003, Dundee (2003), pp. 827 – 838.

T. D. Dyer and R. K. Dhir, “Use of glass cullet as a cement component in concrete,” in: Recycling and Reuse of glass Cullet: Proceedings of International Symposium, Dundee, UK, 19 – 20 March 2001, Dundee (2001), pp. 157 – 166.

W. Remarque, D. Heinz, and Ñ. Schleusser, “Glass powder as a reactive addition for blast furnace cements,” in: Recycling and Reuse of glass Cullet: Proceedings of International Symposium, Dundee, UK, 19 – 20 March 2001, Dundee (2001), pp. 229 – 238.

A. I. Puzanov, S. I. Puzanov, and A. A. Ketov, “Utilization of glass cullet for the production of binding materials,” in: Role for Concrete in Global Development: 17 Proceeding of the International Conference, Dundee, UK (2008), pp. 317 – 324.

S. I. Puzanov, Evaluation of the Complex Impact of Cullet on the Environment and the Improvement of Technologies of Its Re-Use, Author’s Abstract of Candidate’s Thesis [in Russian], Perm State Technological University, Perm (2010).

L. K. Kazantseva, Yu. V. Seretkin, and I. S. Puzanov, “Stability of foam-silicate aggregates against alkali in cement,” Steklo Keram., No. 10, 36 – 42 (2018); L. K. Kazantseva, Yu. V. Seretkin, and I. S. Puzanov, “Stability of foam-silicate aggregates against alkali in cement,” Glass Ceram., 74(9 – 10), 372 – 377 (2018).

L. K. Kazantsev, Yu. V. Seretkin, S. V. Rashchenko, and A. I. Nikitin, “Impact of devitrification of the glass of porous aggregates on the resistance to alkali cement,” Steklo Keram., No. 2, 8 – 14 (2019).

Y. Vapnik, V. V. Sharygin, E. V. Sokol, and R. Shagam, “Paralavas in a combustion metamorphic complex: Hatrurim Basin, Israel,” in: GSA Reviews in Engineering Geology XVIII: Geology of Coal Fires: Case Studies from Around the World (2007), pp. 133 – 153.

E. V. Sokol, O. L. Gas’kova, O. A. Kozmenko, et al., “Clastic dikes of the Hatrurim Basin (western bank of the Dead Sea) — natural analogs of alkaline concretes: mineralogy, chemistry of solutions, long-term stability,” Dokl. Ross. Akad. Nauk, 459(2), 221 – 227 (2014).

E. V. Sokol, S. N. Kokh, Y. Vapnik, et al., “Natural analogues of belite sulfoaluminate cement clinkers from Negev desert, Israel,” Am. Mineral., 99(7), 1471 – 1487 (2014).

A. I. Nikitin, G. I. Storozhenko, L. K. Kazantseva, and V. I. Vereshchagin, “Heat-insulating materials and articles based on trepels from the Potanin deposit,” Stroit. Mater., No. 8, 34 – 38 (2014).

J. F. Charnell, “Gel growth of large crystals of sodium and sodium X zeolites,” J. Cryst. Growth, No. 8, 291 – 294 (1971).

Takayki Ban, Takafumi Ohwaki, Yutaka Ohya, and Yasutaka Takahashi, “Influence of the addition of alkanolamines and tetramethylammonium hydroxide on the shape and size of zeolite-A particles,” Int. J. Inorg. Mater., No. 1, 243 – 251 (1999).

J. Warzywoda, N. Bac, J. C. Jansen, and A. Sacco, Jr., “Growth of zeolite A and X in low earth orbit,” J. Crys. Growth, No. 220, 140 – 149 (2000).

Lama Itani, Yong Liu, Weuping Zhang, et al., “Investigation of the physicochemical changes preceding zeolite nucleation in sodium-rich aluminosilicate gel,” J. Am. Chem. Soc., No. 131, 10127 – 10139 (2009).

L. K. Kazantseva, “Method of obtaining zeolite NaA or NaX, RF Patent for invention, No. 2452688, C01B 39/20, C13B 39/16,” Byull. Izobr. Polezn. Modeli, No. 16 (2012), published June 10, 2012.

L. K. Kazantseva, “Impact of the macro structure of amorphous precursor on the size of zeolites NaAand NaX,” Izv. Ross. Akad. Nauk, Ser. Fiz., 76(10), 1265 – 1268 (2012).

This work was supported by RFBR Grant No. 18-08-00857 and as part of a state task, project No. 0330-2016-0004.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Steklo i Keramika, No. 6, pp. 33 – 40, June, 2019.

Rights and permissions

About this article

Cite this article

Kazantseva, L.K., Nikitin, A.I. & Rashchenko, S.V. Interaction of Foam Ceramic with the Alkaline Medium of Concretes. Glass Ceram 76, 228–234 (2019). https://doi.org/10.1007/s10717-019-00171-w

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10717-019-00171-w