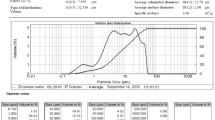

The results of theoretical and experimental studies of methods for obtaining bitstone powder with relative density greater than 0.50 for subsequent sintering of high-density, aluminum oxide based, ceramic samples are presented. The indicated pressing density was achieved by picking the spherical fractional composition of corundum power based on known theoretical models of close regular and random packing of spheres of different size. The prospects for using the described methods in ceramic part fabrication technology are evaluated.

Similar content being viewed by others

References

E. S. Lukin, N. A. Makarov, A. I. Kozlov, et al., “Modern oxide ceramic and its applications,” Konstr. iz Kompozit. Mater., No. 1, 3 – 13 (2007).

G. Parisi and F. Zamponi, “Mean-field theory of hard sphere glasses and jamming,” Rev. Mod. Phys., 82(1), 789 – 845 (2011).

G. A. Tingate, “Some geometrical properties of packings of equal spheres in cylindrical vessels,” Nucl. Eng. Des., 24, 153 – 179 (1973).

N. J. Sloan, “Packing of balls,” V mire Nauki, No. 3, 72 – 82 (1984).

I. Kleiner, Excursions in the History of Mathematics, Birkhäuser – Springer (2012).

T. Aste, “Circle, sphere, and drop packings,” Phys. Rev. E., 53, 2571 (1996).

G. D. Scott and D. M. Kilgour, “The density of random close packing of spheres,” Brit. J. Appl. Phys., 2, 863 – 866 (1969).

O. Pouliquen, M. Nicolas, and P. D. Weidman, “Crystallization of non-Brownian spheres under horizontal shaking,” Phys. Rev. Lett., 79, 3640 – 3643 (1997).

T. P. Bondareva, “Computer modeling of the structure of random packing of systems of spherical particles,” Nauch. Vedom. Belgorod. Gos. Univ., 25(1-1), 78 – 85 (2013).

D. R. Hudson, “Density and packing in an aggregate of mixed spheres,” J. Appl. Phys., 20, 154 (1949); doi: https://doi.org/10.1063/1.1698327.

L. V. Korolev, A. P. Lupanov, and Yu. M. Pridatko, “Dense packing of polydisperse particles in composite building materials,” Sovr. Probl. Nauki obraz., No. 6, Pt. 1, 109 – 114 (2007).

This work was supported by the Ministry of Education and Science of the Russian Federation as part of the government task No. 11.5987.2017/VU of work on ‘Organization of scientific research’ (number for publications: 11.5987.2017/6.7) using equipment from the Center for Collective Use ‘Science-intensive technologies in machine engineering’ at Moscow Polytech.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Steklo i Keramika, No. 6, pp. 14 – 18, June, 2018.

Rights and permissions

About this article

Cite this article

Smirnov, A.V., Tarasovskii, V.P., Ponomarev, S.G. et al. Production of High-Density Bitstone Powder for Sintering Aluminum Oxide Based Ceramic. Glass Ceram 75, 222–225 (2018). https://doi.org/10.1007/s10717-018-0059-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10717-018-0059-9