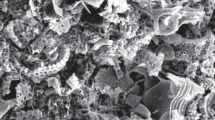

The possibility of eliminating the alkali-silica reaction (ASR-interaction) in foam glass owing to crystallization of glass is examined. It is found that the main crystalline phases in the crystallization of the amorphous phase of foam glass are devitrite (Na2Ca3Si6O16), an octahedral phase (Na4CaSi3O9), and a cristobalitetridimite modification of SiO2. The binary glass ceramic composition of foam material shows significant ASR-interaction diminishment. The tile foam-glass-crystallite (Penosital®) can be glued or plastered with a cement-sand solution and covered with finishing polymer stuccos. The granular foam glass-ceramic can be successfully added as light aggregate to concrete without it disintegrating.

Similar content being viewed by others

References

L. K. Kazantseva and S. V. Rashchenko, “Chemical processes during energy-saving preparation of lightweight ceramics,” J. Am. Ceram. Soc., 97, 1743 – 1743 (2014).

L. K. Kazantseva, D. V. Zheleznov, Yu. V. Seretkin, and S. V. Rashchenko, “Formation of a pore-forming gas source by wetting natural aluminum-silicate with NaOH solution,” Steklo Keram., No. 10, 37 – 42 (2012); L. K. Kazantseva, D. V. Zheleznov, Yu. V. Seretkin, and S. V. Rashchenko, “Formation of a pore-forming gas source by wetting natural aluminum-silicate with NaOH solution,” Glass Ceram., 69(9 – 10), 353 – 359 (2012).

L. K. Kazantseva, “Particulars of foam glass manufacture from zeolite-alkali batch,” Steklo Keram., No. 8, 3 – 7 (2013); L. K. Kazantseva, “Particulars of foam glass manufacture from zeolite-alkali batch,” Glass Ceram., 70(7 – 8), 277 – 281 (2013).

V. Kahlenberg, D. Girtler, E. Arroyabe, et al., “Devitrite (Na2Ca3Si6O16) – structural, spectroscopic and computational investigations on a crystalline impurity phase in industrial soda-lime glasses,” Mineral. Petrol., 100, 1 – 9 (2010).

K. M. Knowles and R. P. Thompson, “Growth of devitrite, Na2Ca3Si6O16, in soda–lime–silica glass,” J. Am. Ceram. Soc., 97, 1425 – 2014 (2014).

K. M. Knowles, B. Li, C. N. F. Ramsey, and R. P. Thompson, “Microstructural characterization of devitrite, Na2Ca3Si6O16,” Adv. Mat. Res., 585, 51 – 55 (2012).

E. N. Gramenitskii, A. V. Kottnl’nikov, A. M. Batanova, et al., Experimental and Technical Petrology [in Russian], Nauchnyi Mir, Moscow (2000).

R. X. Ficher and E. Tillmanns, “Die kristallstrktur von Na4CaSi3O9 und dessen strukturelle beziehungen zu K4SrGe3O9 und Ca3Al2O6,” Zeitschrift fur Kristallographie, 166, 245 – 256 (1984).

J. Schneider, V. R. Mastelaro, H. Panepucci, and E. D. Zanotto, “29Si MAS_NMR studies of Qn structural units in metasilicate glasses and their nucleating ability,” J. Non-Cryst. Solid, 273, 8 – 18 (2000).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Steklo i Keramika, No. 3, pp. 3 – 8, March, 2016.

Rights and permissions

About this article

Cite this article

Kazantseva, L.K., Puzanov, I.S. Crystallization of the Amorphous Phase in Foam Glass as a Method of Decreasing the Alkali-Silicon Reaction. Glass Ceram 73, 77–81 (2016). https://doi.org/10.1007/s10717-016-9829-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10717-016-9829-4