Abstract

This research explores the results of the most common laboratory based indirect tension strength methods over the range of UCS strengths 0.1 MPa (cemented paste backfill) to 100 MPa (concrete). The accuracy of each of the methods is considered through a comparison with direct strength measurements completed on the same material. The results of 241 individual tests suggest that the use of indirect tension methods to determine tension strength for all geo-material strength ranges may provide misleading results unless a correction-factor is applied. Correction factors that relate splitting and flexure results to direct tension results are provided. The correction factors are based on the characteristic UCS of the material. A comparison of the traditional empirical relationship to derive tension from UCS is presented and an updated relationship is proposed that is relevant over the UCS strength range 0.1–100 MPa.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The tension strength of a rock mass is mobilised during excavation when confinement is reduced, and the excavation surface is able to dilate prior to support being installed (Park 2023). At the intact scale, yielding in tension has been identified to commence at 30% of the UCS resulting in the ultimate shear failure of the laboratory sample as individual cracks coalesce under continued loading conditions (Hoek and Martin 2014; Sainsbury and Sainsbury 2017). However, tension strength is seldom directly measured in the laboratory due to limitations associated with project time and costs that affect proper sample preparation and processing (Rabat et al. 2023). As such, the tensile strength of intact geo-material is estimated based on a relationship with UCS or measured via indirect means (Baêsso et al. 2024).

1.1 Empirical Relationship for the Estimation of Tensile Strength

The tensile strength of intact rock is ubiquitously estimated based on a relationship with UCS. This relationship (tension ~ 10% UCS) was derived from a data-set published in Sheorey et al. (1989). The relationship was developed based on a dataset that contains UCS and tension strengths for 23 sedimentary rocks. For the strength properties reported in Sheorey et al. (1989), UCS was measured in only 12 of the 23 cases and Direct Tension (DT) was not measured for any of the samples but estimated based on the results of triaxial testing.

A sub-set of the dataset is presented in Fig. 1 that includes only the datapoints in which UCS was directly measured. The linear trendline of the sub-set datapoints is also provided. The trendline is consistent with the empirical relationship (tension ~ 10%UCS).

Relation between unconfined compressive strength and tension based on direct measurement (modified after Sheorey et al. 1989)

It is known that the tension strengths of geo-materials are influenced by sample mineralogy (Cai 2010; Sainsbury and Kurucuk 2020), and as such, and a ‘one-fit’ empirical relation cannot accurately represent the intact property (Packulak et al. 2022). Previous research conducted on rock samples suggests that the derivation of tension values from “an estimate from UCS gives the most erroneous results” (Perras and Diederichs 2014). Studies completed on a range of rock-types by Perras and Diederichs (2014) suggest tension:UCS ratios of 3–20% that are clearly related to rock-type.

1.2 Indirect Measurements of Tensile Strength

Increased reliability of the tension strength of a geo-material beyond the application of an empirical equation is usually considered through the use of indirect measurements in the field and laboratory. Indirect methods for the quantification of tension strength in the laboratory include flexural (ASTM 2015a; b; Liao et al. 2020) and splitting methods (ISRM 1978; Resan et al. 2020).

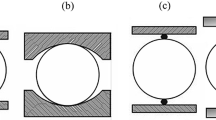

Point load testing (PLT) which can also be considered an indirect measurement technique, has been shown to correlate with tension strength and is easily conducted in the field (Butenuth 1997). However, PLT is usually considered unreliable due to errors associated with machine calibration and operator training (Akbay and Altindag 2020). As such PLT it will not be considered in this study. Authors have also determined relationships between Mode 1 fracture toughness and tensile strength (Ameen et al. 2024). This indirect approach is also not considered in this research. Some generalised loading conditions for indirect tension testing are provided in Fig. 2.

Direct and indirect methods for the measurement of tension strength in the laboratory (modified after Jones and Sainsbury 2023)

For the determination of concrete tension strength, both splitting tensile strength (STS) and flexural three-point bending methods (3PB) are common since samples can be batched to fit the specific mould shapes. Forensic strength investigations on concrete usually require core recovery, and, as such, splitting tests are usually performed in these instances. A usual UCS for concrete is in the range 40–60 MPa (Nazmul et al. 2023). For rocks, splitting methods are the most usual for the determination of tension since samples can be obtained directly from geotechnical core. A typical UCS for rock is in the range 100 MPa but can vary from 1.25 MPa to greater than 200 MPa (Hack and Huisman 2002). Indirect tension tests are performed on low strength cemented paste backfill materials (Johnson et al. 2015; Rankine 2004) that have UCS strengths that range from 0.1 to 10 MPa (Sainsbury et al. 2024). The accuracy of each of these most common indirect approaches (STS and 3PB) is considered in this research over the low to typical strength ranges 0.1–100 MPa.

1.3 Direct Measurement of Tensile Strength

Publications that document the DT strength of rock are limited but are summarised in Perras and Diederichs (2014). Due to their delicate nature, even fewer studies have been completed that measure the tensile strength test of low strength geo-materials materials e.g. cemented paste fill (Grabinsky et al. 2022).

Recent direct tension testing of rock has been completed on dumbbell shaped samples (Li et al. 2013; Jones and Sainsbury 2023). The preparation of dumbbell shaped samples is onerous and not commercially viable at the present time. The sample geometry requires the strength of the material to be able to withstand compression during gripping / seating which is not feasible in this study due to the lower strength range of geo-material being considered. A description of the procedure to establish a reliable DT test procedure is provided in the following section.

2 Laboratory Investigation

2.1 Development of a Reliable Test Procedure

To establish a consistent and reliable procedure for the determination of DT over a wide strength range (0.1–100 MPa) a number of experimental set-ups were trialled. The trials are similar to the experiences documented by Zhang and Lu (2018) for DT testing and are described below.

-

A.

Traditional 50 mm dia. cylindrical samples were bonded to a steel platen that was loaded (Fairhurst 1961). For this procedure, a bonding agent capable of securing the sample with UCS’s of 0.1–100 MPa was difficult to identify. A range of three typical commercial bonding agents were trialled and are documented in Jones and Sainsbury (2023). Trials resulted in high strength samples de-bonding from the platen prior to failure and lower strength samples failing close to the bond location resulting in invalid experimental results. The experimental set-up trialled is presented in Fig. 3a.

-

B.

To increase the bond capacity of the platen to the sample, a screw was be embedded into the sample prior to curing (Alhussainy et al. 2019). During straining of lower strength samples the screw pulled out resulting in invalid experimental results. The experimental set-up trialled is presented in Fig. 3b.

-

C.

The sample bond to the platen was increased through a modified dumbbell geometry that increased the grip/bond area (Hoek 1964). Again, during loading, the samples with higher UCS values de-bond from the platen prior to tensile failure. The experimental set-up trialled is presented in Fig. 3c.

-

D.

To increase the bonding capacity of the platen to the dumbbell shape sample, a screw was embedded into the sample prior to curing. Again, during testing of low strength samples, the screw pulled out resulting in invalid experimental results. The experimental set-up trialled is presented in Fig. 3d.

-

E.

The size of the sample cross sectional area was decreased, and the bond surface area was increased by bonding the sample into endcaps (Hawkes and Mellor 1970). In this case an increased rate of valid tests was achieved but the reliability on the mode of failure was still less than 20% at higher UCS values. The experimental set-up trialled is presented in Fig. 3e. Typical invalid modes of failure presented in Fig. 3f.

Based on the unreliable nature of the traditional techniques for DT testing over the range of UCS values to be tested, the tension response in this study has been established based on a procedure documented by Guo et al. (2022) and Pan and Grabinsky (2021). A bespoke mould and seating arrangement, presented in Fig. 4 has been utilized to ensure only pure tensile strain is applied to the sample eliminating eccentric loading conditions (Zhang et al. 2021).

Side moulds have been printed in a Fortus 450mc Production System with front and back pieces cut from 2 mm Perspex to provide transparency during filling and curing (Fig. 5).

2.2 Sample Preparation

Due to the heterogeneous nature of rock that may provide a significant amount of scatter in results, this investigation has been performed on a series of fine-grain cementitious samples. The samples were prepared from Sika™ 212 High Performance Structural Grout with varying water contents to provide the strength results > 5 MPa and cemented fine-grain tailings at varying binder contents to provide the strength results < 5 MPa. The binder content ranged from 2 to 10% and the water content ranged from 40 to 15% to generate the 0.1 MPa and 5 MPa UCS strengths respectively for the fine-grained cementitious products. Additional details can be found in Sainsbury et al. (2024). The use of a very fine grain material limits heterogeneity within the sample and thus limits the impact of sample scale dependency on the results (Pérez-Rey et al. 2023). As such, cement mortar has been used by many researchers as a proxy for rock (Lee et al. 2013; Duan et al. 2019; Shi et al. 2023) due to its similar UCS, Modulus, Poisson’s ratio, density and brittle failure mode.

Samples were prepared and tested based on the standards and methods provided in Table 1. UCS tests have been performed for each batch of tension results to characterise the compression response.

Samples were mixed in small-scale batches using a commercial 9L Apuro Planetary Mixer. Samples were prepared in three-layers with tamping occurring between each. The samples were individually sealed and cured under zero effective stress at a temperature of 23° and minimum humidity of 50% for 28–29 days prior to testing.

3 Experimental Results

The laboratory tests were completed over the period one-year on three separate Instron Load Frames (10 KN, 50KN and 300 KN capacities) based on the strength requirements. Typical failure modes for a range of strength samples and testing methods are provided in Fig. 6.

Strain rates between 8.33E−05 and 1.67E−04 were applied to the samples (~ extension of 0.25 mm/min). These rates are low enough to ensure that loading induced dynamic effects are not observed in the strength results (Li et al. 2013; Efimov 2020).

3.1 Strength Response

A total of 241 individual tests have been completed and reported on herein. A summary of the results is provided in Fig. 7 along with trendlines for each of the testing method results.

DT results have been fitted with a Power Law trendline that has a R2 value of 89%. The Equation of the trendline is presented in Eq. 1. The DT results have the least scatter of all the testing procedures which is reflected in the high R2 value.

where UCS and DT are defined in MPa.

STS results provide a Power Law trendline (Eq. 2) that has a R2 value significantly less than that of the DT dataset (68%). This wide-scatter in results is consistent with other researchers (Perras and Diederichs 2014). The R2 value suggests that using this technique to determine tension may result in values that vary by up to 30% from the real DT value.

where UCS and STS are defined in MPa.

An equation that can be used to approximate DT from STS is proposed and presented in Eq. 3.

The 3PB measured values are consistently higher than the DT results. This outcome is consistent with literature that suggests flexural strength is greater than DT (Chen et al. 2014) and approximately 200% the DT strength (Fernandes Neto and Haach 2023; Sainsbury et al. 2024). The over-prediction in tensile strength is most pronounced at lower strengths but reduces as UCS increases. The 3PB results have been fitted with a Power Law trendline that has a R2 value of 72%. The equation of the trendline is presented in Eq. 4.

where UCS and 3PB are defined in MPa.

An equation that can be used to approximate DT from 3PB is proposed and presented in Eq. 5.

For each of the test methods the trendlines have been used to compute tension values over the UCS range 0.1–100 MPa. They are presented in Table 2. For comparison purposes it is assumed the DT values are accurate.

Based on the comparisons in Table 2 it can be concluded that:

-

The 3PB method consistently over-predict DT strength. This over-prediction is more pronounced at lower strengths (e.g., cemented paste backfills).

-

STS methods provide significant variability in results and generally seen to under-predict DT strength. This under-prediction is more pronounced at higher strengths. Based on the tests presented herein, STS are more accurate than 3PB tests to characterise the tensile strength of low strength geo-materials (e.g., cemented paste backfills), however, should be considered to under-estimate DT at higher UCS values (> 25 MPa).

Based on the data-set presented in Fig. 7, empirical relationships to convert STS and 3PB strength to DT strengths based on indicative UCS values are presented in Fig. 8. The relationships are presented in Eqs. (6) and (7) respectively.

This Power Law relationship is significantly different to the linear relationship proposed by Tang et al. (2023). The difference arises due to the increased direct tensile strength range of the materials tested in this study that ranged from (0.035 to 100 MPa) to the material tested by Tang et al. (2023) that ranged from 0.01 to 1 MPa.

A relationship relating 3PB strengths to DT strengths over such a strength range has not been proposed before for geo-materials. Relationships exist for modified concrete (e.g. Alkurdi et al. 2020) however these are limited in their application to rock engineering due to the additives included.

3.2 Failure Response

The inaccuracy of each of the indirect testing methods are further explored through a consideration of example stress–strain curves for a range of the samples UCS strengths (1–80 MPa) that are presented in Fig. 9.

Based on the stress–strain curves it is obvious that the post-peak failure responses of the DT samples are perfectly brittle. This represents a pure tensile failure mechanism. The failure responses of the 3PB tests are more ductile at UCS values of 20 MPa and below. Ductility increases as the sample continues to deform representing the compression that is occurring at the loading location and is more pronounced in lower strength (less stiff) geo-materials. The STS responses are more complex and represent a post peak response possibly representing multiple rupture points that coalesce and/or the effect of anisotropy within the sample (Chen et al. 2024). For each of the example stress–strain curves, the modulus has been computed and is provided in Table 3 along with the comparable compression stress–strain result. The modulus has been computed in each of the cases as a tangent at 50% of the peak strength response.

Based on the consideration of the modulus values, the DT and STS are comparable suggesting similar ‘pure’ tension failure modes when the STS tests are performed correctly. It is also observed that when the STS modulus is consistent with the DT modulus, the tension strengths are consistent. This outcome is also observed by Andreev (1991). The modulus results of the 3PB are significantly higher than the DT and STS at UCS values less than 80 MPa. Previous studies have highlighted that if the tension modulus is less than the compression modulus, the tensile strengths derived from indirect techniques are overestimated (Chen and Stimpson 1993). This is certainly the case for the 3PB tests.

3.3 Consideration of the Accuracy of Empirical Relationship to Estimate Tension

The DT results from this study are compared in Fig. 10 with the empirical Sheorey et al. (1989) relationship that is presented as the red trendline and the datapoints used to develop it. Other published datapoints that have previously been referred to in this work are also included for reference.

The current results are consistent with the Sheorey et al. (1989) dataset however, they present less scatter and cover an increased UCS range. Tension results derived from this study and the empirical approach are compared for discrete UCS values and are presented in Table 4.

The empirical relationship is observed to under-estimate tension below UCS values of 22.5 MPa and over-estimate above this based on a comparison of the trendlines in Fig. 10 and can be observed in the values provided in Table 4. When both the current and Sheorey et al. (1989) data are combined, an updated relationship over the UCS range 0.1–100 MPa is defined (black trendline in Fig. 10) that suggests DT strength is higher than 10% the UCS strength. The relationship can be defined as a Power Law with an R2 value of 73% and is presented in Eq. 8.

4 Conclusions

A series of 241 unique laboratory tests have been completed on fine grained cementitious material to compare the results of direct and indirect methods for the measurement of tension. Testing has included direct tension, flexure and splitting strengths over the UCS range 0.1–to 100 MPa.

When indirect tensile strength results are compared to the DT results the following conclusions can be made:

-

STS provides an average approximation to DT results over the range 0.1–100 MPa; however, the methods reliability is 30% less that DT and so many more tests must be completed to provide an ‘average’ result. It is most likely that STS results will be more accurate at lower strength and will under-estimate tension up to 30% at values greater than 10 MPa. An empirical correction factor is presented that is based on indicative UCS that relates STS to DT strength.

-

3PB tests consistently over-predict the tension strength over the UCS range 0.1–100 MPa. This over-prediction is most pronounced at lower strengths and can be related to compressional stresses that build up lower strength samples during straining. An empirical correction factor is presented that is based on the indicative UCS values that relates 3PB strength to DT strength.

The empirical approach to estimate tension based on UCS has been shown to under-estimate tension values below UCS values of 25 MPa and over-estimate tension above this. A new empirical relationship is proposed that includes 241 new datapoint as well as the original 12 datapoints that were measured and documented by Sheorey et al. (1989). The revised empirical relationship has been presented over the UCS strength range 0.1–100 MPa with a R2 value of 89%.

Data Availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Akbay D, Altindag R (2020) Reliability and evaluation of point load index values obtained from different testing devices. J South Afr Inst Min Metall 120:181–190. https://doi.org/10.17159/2411-9717/759/2020

Alhussainy F, Hasan HA, Neaz Sheikh M, Hadi MNS (2019) A new method for direct tensile testing of concrete. J Test Eval. https://doi.org/10.1520/JTE20170067

Alkurdi NM, Mohammad FA (2020) Klalib HA (2020) Mechanical properties and direct tensile strength of waste toner foamed concrete. J Adv Civ Eng Pract Res 11:10–20

Ameen M, Elwageeh M, Abdelaziz A, Elkarmoty M (2024) the effect of rock type and test method on the relationship between MODE I fracture toughness and rock tensile strength. Geotech Geol Eng. https://doi.org/10.1007/s10706-024-02768-7

Andreev GE (1991) A review of the Brazilian test for rock tensile strength determination. Part I: calculation formula. Min Sci Technol 13:445–456. https://doi.org/10.1016/0167-9031(91)91006-4

ASTM Standard C78-b (2015a) Standard test method for flexural strength of concrete (using simple beam with third-point loading). ASTM International, West Conshohocken

ASTM Standard D7972-14 (2015b) Standard test method for flexural strength of manufactured of manufactured carbon and graphite articles using three-point loading at room temperature. ASTM International, West Conshohocken. https://doi.org/10.1520/C0880

Baêsso A, Vargas E, Velloso R, Margues E (2024) Determination of direct tensile strength of rocks using a load converter. Pontical Catholic University of Rio de Janeiro. https://doi.org/10.21203/rs.3.rs-3901070/v1. Accessed Apr 16 2024

Butenuth C (1997) Comparison of tensile strength values of rocks determined by point load and direct tension tests. Rock Mech Rock Eng 30:65–72. https://doi.org/10.1007/BF01020114

Cai M (2010) Practical estimates of tensile strength and Hoek–Brown strength parameter mi of brittle rocks. Rock Mech Rock Eng 43:167–184. https://doi.org/10.1007/s00603-009-0053-1

Chen R, Stimpson B (1993) Interpretation of indirect tensile strength tests when moduli of deformation in compression and in tension are different. Rock Mech Rock Eng 26:183–189. https://doi.org/10.1007/BF01023622

Chen X, Wu S, Zhou J (2014) Strength values of cementitious materials in bending and tension test methods. J Mater Civ Eng 26:484–490. https://doi.org/10.1061/(asce)mt.1943-5533.0000846

Chen Y, Li M, Zhou L et al (2024) Effects of different loading angles on Brazilian splitting characteristics of rock–concrete interface. Geotech Geol Eng. https://doi.org/10.1007/s10706-024-02778-5

Duan G, Li J, Zhang J et al (2019) Mechanical properties and failure modes of rock specimens with specific joint geometries in triaxial unloading compressive test. Adv Mater Sci Eng. https://doi.org/10.1155/2019/1340934

Efimov VP (2020) Experimental study on loading rate effects on the tensile strength and fracture toughness of rocks. Geotech Geol Eng 38:6923–6930. https://doi.org/10.1007/s10706-020-01470-8

Fairhurst CE, Hudson JA (1999) Draft ISRM suggested method for the complete stress-strain curve for intact rock in uniaxial compression. Int J Rock Mech Mining Sci Geomech Abstr 36:279–289

Fairhurst C (1961) Laboratory measurement of some physical properties of rock. In: Proceedings of the 4th symposium on rock mechanics. Bull. Mineral Industries Experiment Station, Pennsylvania State University, Pennsylvania State University, pp 105–118

Fernandes Neto JAD, Haach VG (2023) Flexural and direct tensile strength ratio for concrete unusual cross-sections. Rev IBRACON Estruturas e Mater 16:1–16. https://doi.org/10.1590/s1983-41952023000100004

Grabinsky M, Jafari M, Pan A (2022) Cemented paste backfill (CPB) material properties for undercut analysis. Mining 2:103–122. https://doi.org/10.3390/mining2010007

Guo L, Peng X, Zhao Y et al (2022) Experimental study on direct tensile properties of cemented paste backfill. Front Mater 9:1–10. https://doi.org/10.3389/fmats.2022.864264

Hack R, Huisman M (2002) Estimating the intact rock strength of a rock mass by simple means. In: Proceedings of the 9th congress of the International Association for Engineering Geology and the Environment: Engineering geology for developing countries, 16–20 September 2002. International Association for Engineering Geology and the Environment, Durban, South Africa, pp 1971–1977

Hawkes I, Mellor M (1970) Uniaxial testing in rock mechanics laboratories. Eng Geol 4:177–285. https://doi.org/10.1016/0013-7952(70)90034-7

Hoek E (1964) Fracture of anisotropic rock. J South Afr Inst Min Metall 64:501–518

Hoek E, Martin CD (2014) Fracture initiation and propagation in intact rock—a review. J Rock Mech Geotech Eng 6:287–300. https://doi.org/10.1016/j.jrmge.2014.06.001

ISRM (1978) Suggested methods for determining tensile strength of rock materials. Int J Rock Mech Min Sci 15:99–103. https://doi.org/10.1016/0148-9062(78)90003-7

Johnson JC, Seymour JB, Martin LA et al (2015) Strength and elastic properties of paste backfill at the Lucky Friday Mine, Mullan, Idaho. In: 49th US rock mechanics/geomechanical symposium 2015 ARMA-2015–776, pp 2321–2332

Jones B, Sainsbury B (2023) Characterisation of the tensile performance of bonding agents for the restoration of heritage dimension stone from southeast Australia. Aust J Earth Sci. https://doi.org/10.1080/08120099.2023.2213297

Lee C, Lee D, Jeon S (2013) The influence of excavation damaged zone on the mechanical and thermal behavior of cement mortar block around an opening. KSCE J Civ Eng 17:1263–1274. https://doi.org/10.1007/s12205-013-0206-3

Li H, Li J, Liu B et al (2013) Direct tension test for rock material under different strain rates at quasi-static loads. Rock Mech Rock Eng 46:1247–1254. https://doi.org/10.1007/s00603-013-0406-7

Liao WC, Chen PS, Hung CW, Wagh SK (2020) An innovative test method for tensile strength of concrete by applying the strut-and-tie methodology. Materials (basel) 13:1–20. https://doi.org/10.3390/ma13122776

Nazmul RT, Sainsbury B, Garcez EO, Al-deen S, Ashraf M (2023) Characterisation of the effects of hemp shives for internal curing of concrete. Constr Build Mater 409:133916. https://doi.org/10.1016/j.conbuildmat.2023.133916

Packulak TRM, Mcdonald MR, Jacksteit AC, Day JJ (2022) Determining true tensile strength from brazilian tensile strength laboratory testing. In: GeoCalgary 2022 reflection on resources. Calgary, Alberta

Pan AN, Grabinsky MWF (2021) Tensile strength of cemented paste backfill. Geotech Test J 44:1886–1897. https://doi.org/10.1520/GTJ20200206

Park D (2023) Influence of the Hoek–Brown failure criterion with tensile strength cut-off on the roof stability in deep rock tunnels. Tunn Undergr Sp Technol 136:105016. https://doi.org/10.1016/j.tust.2023.105016

Pérez-Rey I, Muñoz-Ibáñez A, González-Fernández MA et al (2023) Size effects on the tensile strength and fracture toughness of granitic rock in different tests. J Rock Mech Geotech Eng 15:2179–2192. https://doi.org/10.1016/j.jrmge.2022.11.005

Perras MA, Diederichs MS (2014) A review of the tensile strength of rock: concepts and testing. Geotech Geol Eng 32:525–546. https://doi.org/10.1007/s10706-014-9732-0

Rabat Á, Tomás R, Cano M (2023) Assessing water-induced changes in tensile behaviour of porous limestones by means of uniaxial direct pull test and indirect methods. Eng Geol. https://doi.org/10.1016/j.enggeo.2022.106962

Rankine RMA (2004) The geotechnical characterisation and stability analysis of BHP Billiton’s Cannington Mine paste fill. Dissertation James Cook University

Resan SF, Chassib SM, Zemam SK, Madhi MJ (2020) New approach of concrete tensile strength test. Case Stud Constr Mater 12:1–13. https://doi.org/10.1016/j.cscm.2020.e00347

Sainsbury B, Kurucuk N (2020) Impact of intact rock properties on proneness to rockbursting. Bull Eng Geol Environ 79:1939–1946. https://doi.org/10.1007/s10064-019-01670-4

Sainsbury BL, Sainsbury DP (2017) Practical use of the ubiquitous-joint constitutive model for the simulation of anisotropic rock masses. Rock Mech Rock Eng 50:1507–1528. https://doi.org/10.1007/s00603-017-1177-3

Sainsbury B, Harty D, Felipe F et al (2024) Characterisation of the geomechanical properties of cemented paste backfill for design. In: Fourie A, Reid D (eds) Proceedings of Pastefill 2024. Australian Centre for Geomechanics, Perth. https://doi.org/10.36487/ACG_repo/2355_07

Sheorey PR, Biswas AK, Choubey VD (1989) An empirical failure criterion for rocks and jointed rock masses. Eng Geol. https://doi.org/10.1016/0013-7952(89)90003-3

Shi H, Zhang H, Chen W et al (2023) Pull-out debonding characteristics of rockbolt with prefabricated cracks in rock: a numerical study based on particle flow code. Comput Part Mech. https://doi.org/10.1007/s40571-023-00607-9

Tang G, Guo L, Liu G, Yang X (2023) Determination of the relationship between direct tensile test and Brazilian splitting test of cemented tailings backfill. In: Wilson GW, Beier NA, Sego DC, Fourie AB, Reid D (eds) Paste 2023. Australian Centre for Geomechanics, Perth, pp 98–111. https://doi.org/10.36487/ACG_repo/2355_07

Zhang S, Lu Y (2018) Experimental and numerical investigation on the dumbbell-shaped specimen of concrete-like materials under tension. Lat Am J Solids Struct. https://doi.org/10.1590/1679-78254632

Zhang Y, Zhang QY, Zhou XY, Xiang W (2021) Direct tensile tests of red sandstone under different loading rates with the self-developed centering device. Geotech Geol Eng 39:709–718. https://doi.org/10.1007/s10706-020-01515-y

Acknowledgements

Many thanks to the numerous Honours students at Deakin University who have contributed to the laboratory testing database through their engineering research studies. Contributors have included Josh Phelan, Jordan Jones, Ahmad Albaba, Alex Hyland, Hamza Waqar, Rana Saim Ashraf, Abdul Rafay Imran, Maaz Salman, Shui (James) Chen, Nathan Marley and Nasrin Feki.

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions. The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Bre-Anne Sainsbury. Mechanical design and testing for the direct tension results were completed by Angus McDonald. The first draft of the manuscript was written by Bre-Anne Sainsbury and Angus McDonald commented on all versions of the manuscript and read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sainsbury, B., McDonald, A. Consideration of the Accuracy of Empirical and Indirect Laboratory Methods for the Characterisation of Tension Strength. Geotech Geol Eng 42, 4679–4692 (2024). https://doi.org/10.1007/s10706-024-02806-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-024-02806-4