Abstract

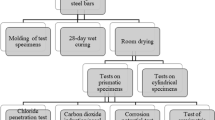

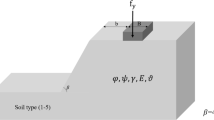

In order to obtain a reasonable plan for synchronous grouting of the shield in anhydrous sandy cobble stratum, based on the basic physical and mechanical characteristics of sandy cobble stratum and local construction conditions, the grouting material was selected, the influence of various factors on mortar performance was analyzed based on orthogonal experiments, and multi-objective optimization of mortar performance was carried out based on BP neural network and genetic algorithm. The results show that bentonite, cement and water are the main factors affecting the consistency of the mortar. The main factors affecting the bleeding rate of the mortar are plain sand, cement, coal ash and bentonite. The main factors affecting the density of the mortar are cement, coal ash, water and bentonite. The main factors affecting the compressive strength of the mortar are cement, sand and bentonite. Based on the multi-objective optimization of mortar performance by BP neural network and genetic algorithm, the optimal mass ratio of mortar is cement (80): coal ash (326): bentonite (40): lime (40): sand (1,068): water (333). Compared with the primary plan obtained by orthogonal experiments, this plan is lower in consistency and bleeding rate within the allowable rang, while the density and strength are higher, and this plan has achieved good practical results in construction. The research results can provide a reference for the selection of mortar ratio under similar formation conditions.

Similar content being viewed by others

Data Availability

All the data in this paper are obtained from tests in this study, and no other data were used to support this study.

References

Brassinga H, Bezuijen A (2001) Modelling the grouting process around a tunnel lining in a geotechnical centrifuge. In: Proceedings of the fifteenth international conference on soil mechanics and geotechnical engineering. [S. l.]: [s. n.], 1455–1458

Dai Z, Bai Y, Liao S, Peng F. (2011) Study on the law of grout pressure dissipation in simultaneous backfill grouting during shield tunneling in soft soils. In Geo-Frontiers 2011: advances in geotechnical engineering, pp 2947–2957. https://doi.org/10.1061/41165(397)302

Ezzeldine OY (1999) Estimation of the surface displacement field due to construction of cairo metro line El Khalafawy-St. Therese. Tunn Undergr Space Technol 14(3):267–279

Gou CF, Ye F, Zhang JL, Liu YP (2013) Ring distribution model of filling pressure for shield tunnels under synchronous grouting. Chin J Geotech Eng 35(3):590–598 (In Chinese)

Gou CF, Ye F, Ji M, Sun HD (2016) Cylindrical cavity pressure—filter diffusion model for backfill grouting of shield tunnel. J Railw Sci Eng 13(2):325–331 (In Chinese)

Han C, Zhang W, Zhou W, Guo J, Yang F, Man X, Wang H (2020) Experimental investigation of the fracture grouting efficiency with consideration of the viscosity variation under dynamic pressure conditions. Carbonates Evaporites 35(2):1–12. https://doi.org/10.1007/s13146-020-00568-7

Hashimoto T, Konda T, Brinkman J, et al (2004a) Simultaneous backfill grouting, pressure development in construction phase in the long-term. In: Proceedings of the 30th ITA-A ITES world tunnel congress. Singapore: [s.n.]: 52–59

Hashimoto T, Brinkman J, Kano T, Feddem A (2004b) Simultaneous backfill grouting, pressure development in construction phase and in the long-term. Tunn Undergr Space Technol 19:447

Jiang H, Zhou S, Di H, Ye W, Liu Z, Zhao Y (2021) Earth pressure and internal forces of tunnel lining in jet grouting reinforced mud stratum. KSCE J Civ Eng 25(10):4005–4017. https://doi.org/10.1007/s12205-021-2014-5

Jiao W, Ding Y, Zhang K et al (2016) Study on slurry performance of new type synchronous grouting in shield construction. Construction Technology 45:484–487 (in Chinese)

Jin L, Peng G, Han A, Wu Y, Li T (2016) Contrast test for the applicability of the fluidity index of simultaneous grouting mortar. Sci Technol Eng 16(32):303–307 (In Chinese)

Liang Y, Yang J, Wang S, Zeng X (2015) A study on grout consolidation and dissipation mechanism during shield backfilled grouting with considering time effect. Rock Soil Mech 36(12):3373–3380 (In Chinese)

Qi W, Yang Z, Jiang Y, Yang X, Shao X, An H (2021) Experimental study on fresh state properties of single-liquid semi-inert synchronous grouting for shield tunnels in water-rich sand strata. Arab J Sci Eng. https://doi.org/10.1007/s13369-021-06220-3

Qiao Y, Zhao T, Ding W (2018) Simulating synchronous grouting in shield tunnels with the consideration of evolution of grouting pressure. In: GeoShanghai International Conference. Springer, Singapore, pp 23–31. https://doi.org/10.1007/978-981-13-0017-2_2

Yang X, Su D, Zhou B, Liu Z, Zhou C (2016) Experiment study on similarity ratio of similar material for model test on red-bed soft rock. Rock Soil Mech 37(8):2231–2237 (In Chinese)

Ye F, Gou C, Chen Z, Liu Y, Zhang J (2013) Backfilled grouts diffusion model of shield tunnel considering iIts viscosity degeneration. China J Highw Transp 26(1):127–134 (In Chinese)

Zhang F, Zhu H, Fu D (2013) Shield tunnel. Beijing: China Communications Press, 2004. (In Chinese)

Zhao B, Wang X, Zhang C, Li W, Abbassi R, Chen K (2020) Structural integrity assessment of shield tunnel crossing of a railway bridge using orthogonal experimental design. Eng Fail Anal 114:104594. https://doi.org/10.1016/j.engfailanal.2020.104594

Zhou L, Mao W, Shi M (2013) Optimized design of grout mix proportion for synchronous grouting in shield tunneling. J Wuhan Inst Technol 35(9):29–33 (In Chinese)

Zhou S, Li X, Ji C, Xiao J (2017) Back-fill grout experimental test for discharged soils reuse of the large-diameter size mortar shield tunnel. KSCE J Civ Eng 21(3):725–733. https://doi.org/10.1007/s12205-016-0856-z

Acknowledgements

This work was supported by Chongqing University of Science and Technology Graduate Students’ Science and Technology Innovation Program (YKJCX2120657, YKJCX2020654).

Funding

Chongqing University of Science and Technology Graduate Students’ Science and Technology Innovation Program, YKJCX2120657, Liyun Zhang, YKJCX2020654, Liyun Zhang

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that, with regard to the publication of this paper and the funding for publishing it, there are no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, X., Jiang, B., Zhang, L. et al. Study on Optimization of Shield Synchronous Grout Injection in Anhydrous Sand Cobble Formation. Geotech Geol Eng 41, 577–588 (2023). https://doi.org/10.1007/s10706-022-02302-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-022-02302-7