Abstract

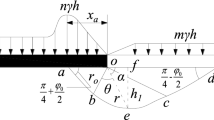

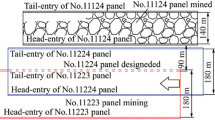

During the mining process of short distance coal seams group with high gas content, excavation of the protective coal seam will result in stress relief and fracture development which provides pathways for gas migration. Gas stored in the lower coal seam moves along the mining-induced fracture to the floor of the upper working face, which may cause the gas over-limit at the upper coal seam. This paper takes the short distance coal seams group in Xinghua coal mine as an example, theoretical analysis, numerical simulation and field monitoring are comprehensively applied to study the floor failure mechanism, pressure relief law and dynamic evolution of cracks induced by the mining of the second-right working face. The results showed that as the upper coal seam gradually advances, the pressure relief angle of roof and floor gradually decreases, and the pressure relief range and floor failure depth gradually increase. After the working face of the upper coal seam is advanced 100 m, the range of the pressure relief in the surrounding coal and rock masses approaches stable; the cracks in the shallow depth are mainly with small angles or type II shear cracks, and the cracks in the large depth are mainly shear-expansion with lager angles, and the amount of fractures in the floor reduces with the increase of the depth of the floor. It was found that the mining-induced fractures in the floor is distributed in the shape of an “O” ring, and as the working face advances, the range of this “O”-shaped crack circle keeps moving forward but the width of the crack circle is basically unchanged. Finally, the low-level drilling field was used to control the gas from lower coal seams according to the stress relief and fracture distribution law, which achieved satisfied application effect and provided guidance for mine gas extraction in similar mining conditions.

Similar content being viewed by others

References

Cheng ZH, Qi QX, Li HY et al (2016) Evolution of the superimposed mining induced stress-fissure field under extracting of close distance coal seam group. J China Coal Soc 41(2):367–375 (in Chinese)

Díaz AMB, González NC (2007) Control and prevention of gas outbursts in coal mines, Riosa-Olloniego coalfield, Spain. Int J Coal Geol 69:253–266

Flores RM (1998) Coalbed methane: from hazard to resource. Int J Coal Geol 35:3–26

Hu YB, Li WP, Wang QQ et al (2019) Study on failure depth of coal seam floor in deep mining. Environ Earth Sci 78:697

Kong DZ, Cheng ZB, Zheng SS (2019) Study on the failure mechanism and stability control measures in a large-cutting-height coal mining face with a deep-buried seam. B Eng Geol Environ 78(8):6143–6157

Levasseur S, Charlier R, Frieg B et al (2010) Hydro-mechanical modelling of the excavation damaged zone around an underground excavation at Mont Terri Rock Laboratory. Int J Rock Mech Min 47(3):414–425

Li J (2003) A review of techniques, advances and outstanding issues in numerical modelling for rock mechanics and rock engineering. Int J Rock Mech Min 40(3):283–353

Li LC, Tang CA, Wang SY (2012) A numerical investigation of fracture infilling and spacing in layered rocks subjected to hydro-mechanical Loading. Rock Mech Rock Eng 45:753–765

Li W, Cheng YP, Guo PK et al (2014) The evolution of permeability and gas composition during remote protective longwall mining and stress-relief gas drainage: a case study of the underground Haishiwan Coal Mine. Geosci J 18(4):427–437

Li SG, Ding Y, An ZF et al (2016) Experimental research on the shape and dynamic evolution of repeated mining-induced fractures in short-distance coal seams. J Min Safety Eng 33(5):904–910 (in Chinese)

Li CY, Zhang Y, Zhang GJ et al (2018) Crack propagation mechanisms and stress evolution of floor under dynamic disturbance in deep coal mining. Chin J Geotech Eng 40(11):2031–2040 (in Chinese)

Liu SC, Liu XM, Jiang ZH et al (2009) Research on electrical prediction for evaluating water conducting fracture zones in coal seam floor. China J Rock Mech Eng 28(2):348–356

Lu YL, Wang LG (2015) Numerical simulation of mining-induced fracture evolution and water flow in coal seam floor above a confined aquifer. Comput Geotech 67:157–171

National Coal Mine Safety Administration (2016) Safety Regulation for Coal Mining. China Coal Industry Publishing House, Beijing (in Chinese)

Noack K (1998) Control of gas emissions in underground coal mines. Int J Coal Geol 35:57–82

Peng YW, Qi QX, Wang YG et al (2010) Study of field measurement of mining-induced coal fracture field and its application. Chin J Rock Mech Eng 29(S2):4188–4193 (in Chinese)

Peng GY, Gao MZ, Lv YC et al (2019) Investigation on mining mechanics behavior of deep close distance seam group. J China Coal Soc 44(7):1971–1980 (in Chinese)

Wang JC, Xu YC, Xu GM et al (2010) Application of mine electric profiling method to detect floor failure depth of coal mining face. Coal Sci Technol 38(1):97–100 (in Chinese)

Wang FT, Zhang C, Liang NN (2017) Gas permeability evolution mechanism and comprehensive gas drainage technology for thin coal seam mining. Energies 10:1382

Yang W, Lin BQ, Qu YA et al (2011) Mechanism of strata deformation under protective seam and its application for relieved methane control. Int J Coal Geol 85(3):300–306

Zhang BS (2008) Study on the surrounding rock control theory and technology of ultra-close multiple-seams mining. Doctoral Dissertation, Taiyuan University of Technology, Taiyuan, p 27

Zhang CL (2017) Fracture development and stress relief with space influenced by mining of coal seams group. Doctoral Dissertation, China University of Mining and Technology, Beijing

Zhang PS, Liu SD (2004) Observation of overburden failure of coal seam by CT of seismic wave. Chin J Rock Mech Eng 23(15):2510–2513 (in Chinese)

Zhang CL, Zhang Y (2016) Stress and fracture evolution based on abutment change in thick coal aeam—A case study in china colliery. Electron J Geotech Eng 21:4369–4386

Zhang BS, Kang LX, Zhai YD (2005) Definition of ultra-close multiple-seams and its ground pressure behavior. In: The 24th international conference on ground control in mining, Morgantown, W.V., pp 110–113

Zhang Y, Zhang CL, Zhao F (2015) Dynamic evolution rules of mining-induced fractures in different floor area of short-distance coal seams. J China Coal Soci 40(4):786–792 (in Chinese)

Zhang CL, Yu L, Feng RM et al (2018) A numerical study of stress distribution and fracture development above a protective coal seam in longwall mining. Processes 6(9):146

Zhu WC, Bruhns OT (2008) Simulating excavation damaged zone around a circular opening under hydromechanical conditions. Int J Rock Mech Min 45(5):815–830

Zhu B, Wu Q, Yang JW et al (2013) Study of pore pressure change during mining and its application on water inrush prevention: a numerical simulation case in Zhaogezhuang coalmine, China. Environ Earth Sci 71(5):1–18

Acknowledgements

This paper was supported by the State Key Research Development Program of China (Grant No. 2016YFC0600708), the National Natural Science Foundation of China (51804129, 51808246, 51904112), the Jiangsu Post-doctoral Research Funding Project (2019K139), science and technology projects of Monistry of Housing and Urban–Rural Development of the People’s Republic of China (2017K6004), and the Foundation of Huaiyin Institute of Technology. The authors would also like to express special thanks to the editor and anonymous reviewers for their professional and constructive suggestion.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, C., Feng, R., Zhang, X. et al. Numerical Study on Stress Relief and Fracture Distribution Law of Floor in Short-Distance Coal Seams Mining: A Case Study. Geotech Geol Eng 39, 437–450 (2021). https://doi.org/10.1007/s10706-020-01502-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-020-01502-3