Abstract

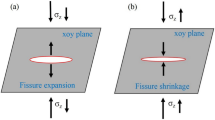

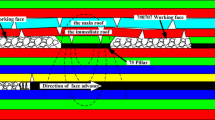

Under the circumstance that lower protective seam mining may give rise to mining-induced fracture development in the upper coal and rock mass, the key to gas extraction during lower protective seam mining is investigated based on mining-induced fracture development law of overlying strata. Fracture evolution processes are seldom described by the traditional “Three Zone” theory of overlying strata. Consequently, its field application in gas extraction during the lower protective seam mining is limited. While theoretical analysis and analog simulation are adopted to analyze mining-induced fracture development rules for the lower protective seam mining, a plastic hinge is selected to theoretically derive a process from internal fracture development to occurrence of rock beam fracturing. In combination with the theory of key strata that the movement of overburden is controlled by key bond strata, a computing method is obtained to figure out development height of a gas conducting fissure zone during the lower protective seam mining. Taking geological conditions in Jinjia Coal Mine as the engineering background, development height of the gas conducting fissure zone in No. 22 seam there is calculated to be 42.2 m. On this basis, engineering design is performed for pressure relief gas extraction of the lower protective seam mining. During working face mining, gas emission quantity and sources are also monitored according to gas conducting features of strata within a range of the gas conducting fissure zone. Hence, accuracy in development range computations for this zone is verified. As demonstrated by research findings, combining the plastic hinge theory with a control action of key strata has the potential to effectively work out development height of the gas conducting fissure zone during the lower protective seam mining. Without a doubt, an accurate theoretical basis can be provided for pressure relief gas extraction in the course of lower protective seam mining.

Similar content being viewed by others

References

Bai M, Elsworth D (1990) Some aspects of mining under aquifers in China. Min Sci Technol 10(1):81–91

Cheng YP, Yu QX, Yuan L et al (2004) Experimental research of safe and high-efficient exploitation of coal and pressure relief gas in long distance. J China Univ Min Technol 33(2):132–136

Dai S, Han B, Liu SL et al (2020) Neural network-based prediction methods for height of water-flowing fractured zone caused by underground coal mining. Arab J Geosci 13(11):537–559

Huang BX, Liu CY, Xu JL (2010) Research on through degree of overlying strata fracture fissure induced by mining. J China Univ Min Technol 39(1):45–49

Kong D, Cheng Z, Zheng S (2019) Study on failure mechanism and stability control measures in large-cutting-height coal mining face with deep-buried seam. Bull Eng Geol Environ 78(8):6143–6157

Li SQ, Long ZG, Luo WD et al (2012) Numerical simulation of protection scope when lower-protective layer mined in coal seams. China Saf Sci J 22(6):34–40

Li SQ, Xue XQ, Li SQ et al (2013) Experimental research on strata movement and fracture dynamic evolution of double pressure-relief mining in coal seams group. J China Coal Soc 38(12):2146–2152

Liu Y, Liu QM, Li WP et al (2019) Height of water-conducting fractured zone in coal mining in the soil-rock composite structure overburdens. Environ Geol 78(7):1–13

Lu P, Yuan L, Cheng H et al (2010) Theory and experimental studies of enhanced gas drainage in the high-gas face of low permeability coal multi-seams. J China Coal Soc 35(4):580–585

Ning JG, Wang J, Tan YL et al (2020) Mechanical mechanism of overlying strata breaking and development of fractured zone during close-distance coal seam group mining. Int J Min Sci Technol 30(2):207–215

Qian MG, Miao XX, Xu JL (1996) Theoretical study of key stratum in ground control. J China Coal Soc 21(3):225–230

Wang JC, Wu RL, Zhang P (2015) Characteristics and applications of gas desorption with excavation disturbances in coal mining. Int J Coal Sci Technol 2(1):30–37

Wu RL (2013) Effect of key stratum on the scope of the three zones of gas pressure relief and migration in coal seam group mining. J China Coal Soc 38(6):924–929

Wu RL, Wang JL, She ZL et al (2017) Effects of mining height on range of three zones of gas pressure relief and migration in overlying strata. J Min Saf Eng 34(6):1223–1231

Xie HP, Gao F, Zhou HW et al (2013) On theoretical and modeling approach to mining-enhanced permeability for simultaneous exploitation of coal and gas. J China Coal Soc 38(7):1101–1108

Xu JL, Qian MG, Jin HW (2004) Study on coal and coal-bed methane simultaneous extraction technique on the basis of strata movement. J China Coal Soc 33(2):129–132

Xu JL, Zhu WB, Wang XZ (2012) New method to predict the height of fractured water-conducting zone by location of key strata. J China Coal Soc 37(5):762–769

Xue DJ, Zhou HW, Kong L et al (2012) Mechanism of unloading-induced permeability increment of protected coal seam under mining. Chin J Geotech Eng 34(10):1910–1916

Yuan L, Guo H, Shen BT et al (2011) Circular overlying zone at longwall panel for efficient methane capture of mutiple coal seams with low permeability. J China Coal Soc 36(3):357–365

Zhang L, Jiang Y (1999) Effect of yield strength on the plastic rotational factor of three-point bend specimen. J Harbin Univ Sci Technol 4(4):105–107

Zhang Y, Cao SG, Guo S et al (2018) Mechanisms of the development of water-conducting fracture zone in overlying strata during shortwall block backfill mining: a case study in Northwestern China. Environ Earth Sci 77(14):1–17

Zhao X, Han ZL, Han SQ et al (2013) Mining protection scope determination of low protective seam in contiguous seams. Coal Sci Technol 41(10):53–56

Zhu X (1996) The calculating method about the plastic rotational factor of beam during the process of dynamic plastic fracture. Struct Environ Eng 24(4):28–36

Acknowledgements

A general Project supported by the National Natural Science Foundation of China (51974117); a project supported by an open-end fund of the Work Safety Key Lab on Prevention and Control of Gas and Roof Disasters for Southern Coal Mines (E21822); and, a youth Project supported by the National Natural Science Foundation of China (51804114).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhao, X., Feng, T., Li, S. et al. Development Range Determination of Gas Conducting Fissure Zones for Lower Protective Seam Mining in JINJIA Coal Mine. Geotech Geol Eng 39, 397–409 (2021). https://doi.org/10.1007/s10706-020-01499-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-020-01499-9