Abstract

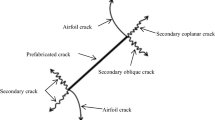

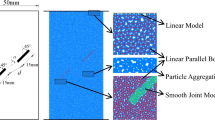

In order to obtain the mechanical strength and failure characteristics of fractured rock masses with prefabricated closed crack, Based on the indoor uniaxial compression test, the parameters of the prefabricated closed crack specimens were calibrated. The PFC3D software was used to perform the uniaxial compression simulation test on the prefabricated closed crack rock-like material. The change rules of mechanical parameters of fractured specimens with different prefabricated closed cracks and the failure morphology of rock specimens were obtained. The results showed that: most of the parameters such as elastic modulus, secant modulus, deformation modulus, peak strength and peak strain of the specimen showed a downward trend with the increase of crack diameter and inclination. Among all the parameters, the change of crack inclination angle and diameter had the greatest impact on the Peak strength, and the least influence on Secant modulus; Micro cracks mainly occurred around the prefabricated crack, and when the diameter of prefabricated cracks was small, micro cracks outside the prefabricated cracks were more likely to appear; With the increase of crack diameter and inclination angle, the stress at the moment when the first micro crack appears first decreased and then increased; The growth process of the number of micro cracks had gone through three stages: the stage of no micro cracks, the stage of unstable growth of micro cracks and the stage of rapid growth of micro crack.

Similar content being viewed by others

References

Atkinson KB (1984) Subcritical crack growth in geological materials. J Geophys Res 89(B6):4077–4114

Bobet A, Einstein HH (1998) Fracture coalescence in rock-type material under uniaxial and biaxial compression. Int J Rock Mech Min Sci 35(7):863–888

Brace WF, Bombolakis EG (1963) A note on brittle crack growth in compression. J Geophys Res 68(12):3709–3713

Cen DF, Huang D (2014) Mesoscopic displacement modes of crack propagation of rock mass under uniaxial compression with high strain rate. J China Coal Soc 39(03):436–444 (in Chinese)

Chen PY (2015) Characteristics analysis of slop structure and stability study on high rock slope: a case study of the high rock slopes in longsi mine, Jiaozuo city. China University of Geosciences, Wuhan (in Chinese)

Fang Z, Harrison JP (2003) Development of local degradation approach to the modelling of brittle fracture in heterogeneous rocks. Int J Rock Mech Min Sci 39(4):443–457

Fu JW, Zhu WS, Xie FD, Xue WQ, Zhang DF, Li Y (2013) Experimental studies and elasto-brittle simulation of propagation and coalescence process of two three-dimensional flaws in rocks. Rock Soil Mech 34(09):2489–2495 (in Chinese)

Goodman RE, Taylor RL, Brekke TL (1968) A model for the mechanics of jointed rock. J Soil Mech Found Div 94:637–660

Jiang MJ, Chen H, Zhang N, Fang R (2014) Distinct element numerical analysis of crack evolution in rocks containing pre-existing double flaw. Rock Soil Mech 35(11):3259–3268 (in Chinese)

Liu HW, Yang C (2016) Micro-analysis of uniaxial compression of cracked rock containing open or closing fissure based on PFC. Water Resour Power 34(01):131–135 (in Chinese)

Nolen-Hoeksema RC, Gordon RB (1987) Optical detection of crack patterns in the opening-mode fracture of marble. Int J Rock Mech Min Sci Geomech 24(2):135–144

Park CH, Bobet A (2010) Crack initiation, propagation and coalescence from frictional flaws in uniaxial compression. Eng Fract Mech 77(14):2727–2748

Pu CZ, Cao P, Chen Y, Yi YL, Zhang XY (2011) Fracture test and failure mechanism of rock-like material of relatively different fracture apertures. J Central South Univ (Sci Technol) 42(08):2394–2399 (in Chinese)

Tang CA, Zhao W (1997) RFPA2D system for rock failure process analysis. Chin J Rock Mech Eng 016(005):507–508 (in Chinese)

Tang C (1997) Numerical simulation of progressive rock failure and associated seismicity. Int J Rock Mech Min Sci 34(2):249–261

Xie QT, Guo JZ, Wang JL, Chen YG (2011) A study of crack propagation measurement on sandstone with a single inclined flaw under uniaxial compression. Rock Soil Mech 32(10):2917–2921 (in Chinese)

Yang TH, Tu XL, Yu B, Zhang YB, Li LC, Tang CA, Tan GH (2005) A micro mechanical model for simulating the coupling of fracture and flow of rock. Chin J Solid Mech 026(003):333–337 (in Chinese)

Zhong BB, Zhang YB, Li H (2014) Study of mechanisms of crack propagation of rock based on RFPA2D. J Wuhan Univ Technol 36(02):82–88 (in Chinese)

Zhang B, Li SC, Zhang DF, Li MT, Shao DL (2012) Uniaxial compression mechanical property test, fracture and damage analysis of similar material of jointed rock mass with filled cracks. Rock Soil Mech 33(06):1647–1652 (in Chinese)

Zhao C, Tian JS, Hiroshi MATSUDA et al (2015) Crack propagation and damage of rock under uniaxial compression based on global strain field analysis. Chin J Rock Mech Eng 34(04):763–769 (in Chinese)

Zhang GK, Li HB, Wang MY, Li XF (2019) Crack propagation characteristics in rocks containing single fissure based on acoustic testing and camera technique. Rock Soil Mech 40(S1):63–72 (in Chinese)

Zhang WQ, Wang ZC (2018) Research and application of mechanism of water inrush in fault (secondary fault) activation after coal extraction. China University of Mining and Technology press (Monograph) (in Chinese)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (51774199).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, L., Zhu, J. Analysis of Mechanical Strength and Failure Morphology of Prefabricated Closed Cracked Rock Mass Under Uniaxial Compression. Geotech Geol Eng 38, 4905–4915 (2020). https://doi.org/10.1007/s10706-020-01335-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-020-01335-0