Abstract

Daily increase in plastic waste amounts is a serious environmental problem and it is among the major challenges worldwide. Reusing this waste material can be therefore an appropriate solution to overcome this problem. Besides, recycling plastic waste as reinforcing material has become a cheap and viable alternative for soil improvement schemes. In the current study, PET plastic waste strips (water bottles) were randomly mixed with sandy soil to improve the soil strength parameters. Due to the lack of comprehensive seismic studies on soils reinforced with PET strips, a series of 1-g shaking table tests was performed to evaluate the dynamic properties of the sand-PET mixtures with different PET contents (0%, 0.5%, 0.75% and 1% by the sand weight) and aspect ratios (1 and 5). Effect of various parameters, including excitation amplitude, PET strip content and PET strip aspect ratio on response of the mixtures were elaborated. It was found that addition of the PET strips to the sand, could reduce the soil brittleness under low overburden pressures. Therefore, at the inclusion ranges used in this study, increase of the PET strips content or aspect ratio, caused an increase in the damping ratio and decrease in the shear modulus values compared to the plain sand model. Opposite trends of PET strips inclusion contribution were reported under the influence of high overburden pressures through carrying out some cyclic large-scale direct shear tests.

Similar content being viewed by others

Abbreviations

- \(A_{loop}\) :

-

Total loop area in the hysteresis loop

- \(A_{triangle}\) :

-

Area of the triangle in the hysteresis loop

- A R :

-

Aspect ratio

- C c :

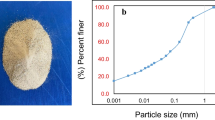

-

Coefficient of curvature

- C u :

-

Coefficient of uniformity

- D :

-

Damping ratio

- D 10 :

-

Diameter of particles at 10% finer

- D 50 :

-

Mean diameter of the particles

- D r :

-

Target relative density

- G :

-

Shear modulus

- G s :

-

Specific gravity

- \(\tau_{max}\) :

-

Maximum shear stress

- \(\tau_{min }\) :

-

Minimum shear stress

- \(\gamma_{d}\) :

-

Dry unit weight

- \(\gamma_{{d_{max} }}\) :

-

Maximum dry unit weight

- \(\gamma_{{d_{min} }}\) :

-

Minimum dry unit weight

- W elastic :

-

Elastic work

- W PET :

-

Dry weight of the PET strips

- W Sand :

-

Dry weight of the sand

- Z :

-

Depth

- ∆W :

-

Net work

- ∆Z :

-

Spacing interval

- ∆τ :

-

Total shear stress variation

- ∆ γ :

-

Total shear strain variation

- τ :

-

Shear stress

- γ :

-

Shear strain

- γ max :

-

Maximum shear strain

- γ min :

-

Minimum shear strain

- \(\rho\) :

-

Density

- η :

-

Weight fraction of PET

- \(\ddot{u}\) :

-

Horizontal acceleration

References

Acharyya R, Lahiri A, Mukherjee SP, Raghu PV (2013) Improvement of undrained shear strength of clayey soil with PET bottle strips. In: Proceedings of Indian Geotechnical Conference, Roorkee

Alaie R, Jamshidi Chenari R (2018) Design and performance of a single axis shake table and laminar soil container. Civil Eng J 4(6):1326–1337

ASTM D2487. Standard practice for classification of soils for engineering purposes (unified soil classification system). ASTM International, West Conshohocken

ASTM D4253. Standard test methods for maximum index density and unit weight of soils using a vibratory table. ASTM International, West Conshohocken

ASTM, D638. Standard test method for tensile properties of plastics. ASTM International, West Conshohocken

ASTM D854. Standard test methods for specific gravity of soil solids by water pycnometer. ASTM International, West Conshohocken

Babu GS, Chouksey SK (2011) Stress–strain response of plastic waste mixed soil. Waste Manag 31(3):481–488

Botero E, Ossa A, Sherwell G, Ovando-Shelley E (2015) Stress–strain behavior of a silty soil reinforced with polyethylene terephthalate (PET). Geotext Geomembr 43(4):363–369

Brennan AJ, Thusyanthan NI, Madabhushi SP (2005) Evaluation of shear modulus and damping in dynamic centrifuge tests. J Geotech Geoenviron Eng 131(12):1488–1497

Consoli NC, Montardo JP, Donato M, Prietto PDM (2004) Effect of material properties on the behavior of sand-cement-fiber composites. Proc Inst Civil Eng Ground Improv 8(2):77–90

Consoli NC, Montardo JP, Prietto PDM, Pasa GS (2002) Engineering behavior of a sand reinforced with plastic waste. J Geotech Geoenviron Eng 128(6):462–472

Consoli NC, Vendruscolo MA, Fonini A, Dalla Rosa F (2009) Fiber reinforcement effects on sand considering a wide cementation range. Geotext Geomembr 27(3):196–203

Consoli NC, Vendruscolo MA, Prietto PDM (2003) Behavior of plate load tests on soil layers improved with cement and fiber. J Geotech Geoenviron Eng 129(1):96–101

de Mello D, Pezzin SH, Amico SC (2009) The effect of post-consumer PET particles on the performance of flexible polyurethane foams. Polym Test 28(7):702–708

Deng A, Xiao Y (2010) Measuring and modeling proportion-dependent stress-strain behavior of EPS-sand mixture 1. Int J Geomech 10(6):214–222

Dhatrak AI, Konmare SD (2015) Performance of randomly oriented plastic waste in flexible pavement. Int J Pure Appl Res Eng Technol (IJPRET) 3(9):193–202

Divya PV, Viswanadham BVS, Gourc JP (2018) Hydraulic conductivity behaviour of soil blended with geofiber inclusions. Geotext Geomembr 46(2):121–130

ECO PET (2007) https://www.ecopet.eu/Domino_english/ecopet.htm. Accessed 13 Sept 2010

Hardin BO, Drnevich VP (1972) Shear modulus and damping in soils. J Soil Mech Found Div ASCE 98(7):667–692

Jamshidi Chenari R, Twoahata I, Ghiassian H, Tabarsa R (2010) Experimental evaluation of dynamic deformation characteristics of sheet pile retaining walls with fiber reinforcement backfill soil. J Soil Dyn Earthq Eng 30:438–446

Jamshidi Chenari R, Bakhshipour S (2016) Laboratory investigation on the effect of waste plastic strips on strength properties of sand materials. In: Proceedings of 3rd National and 1st international conference in applied research on civil engineering, architecture & urban planning, K.N University of Technology, Iran (in Persian)

Kalumba D, Chebet FC (2013) Utilisation of polyethylene (plastic) shopping bags waste for soil improvement in sandy soils. In: Proceedings of the 18th ICSMGE

Mahali KP, Sinha AK (2015) Utilization of stonedust with plastic waste for improving the subgrade in highway pavement construction. Int J Res Eng Technol 4(6):29–35

Malidarreh NR, Shooshpasha I, Mirhosseini SM, Dehestani M (2018) Effects of reinforcement on mechanical behaviour of cement treated sand using direct shear and triaxial tests. Int J Geotech Eng 12(5):491–499

Mondal PK (2012) Behaviour of a clayey soil mixed with plastic waste. Thesis of Civil Engineering Dept. Jadavpur University Kolkata

Nsaif MH (2013) Behavior of soils strengthened by plastic waste materials. J Eng Sustain Dev 17(4):182–194

Peddaiah S, Burman A, Sreedeep S (2018) Experimental study on effect of waste plastic bottle strips in soil improvement. Geotech Geol Eng 36(5):2907–2920

Rao GV, Dutta RK (2004) Ground improvement with plastic waste. In: Proceeding, 5th international conference on ground improvement technique, Kaulalumpur, Malaysia, pp 321–328

Sadek S, Najjar SS, Freiha F (2010) Shear strength of fiber-reinforced sands. J Geotech Geoenviron Eng 136(3):490–499

Santoni RL, Tingle JS, Webster S (2001) Engineering properties of sand fiber mixtures for road construction. J Geotech Geoenviron Eng 127(3):258–268

Seed HB, Idriss IM (1970) Soil moduli and damping factors for dynamic response analysis. In: EERC, University of California, Berkeley, vol 70(10)

Sobhan K, Mashnad M (2002) Tensile strength and toughness of soil–cement–fly-ash composite reinforced with recycled high-density polyethylene strips. J Mater Civ Eng 14(2):177–184

Zeghal M, Elgamal AW, Tang HT, Stepp JC (1995) Lotung downhole array. II: Evaluation of soil nonlinear properties. J Geotech Eng 121(4), 363–378.

Zhu W, Li M, Zhang C, Zhao G (2008) Density and strength properties of sand-expanded polystyrene beads mixture. In: GeoCongress 2008: characterization, monitoring, and modeling of GeoSystems, pp 36–43

Acknowledgements

The authors would like to acknowledge University of Guilan with thanks for the access to its laboratory equipment. The authors also would like to thank the reviewers and the editor for their valuable suggestions to improve the manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fathi, H., Jamshidi Chenari, R. & Vafaeian, M. Shaking Table Study on PET Strips-Sand Mixtures Using Laminar Box Modelling. Geotech Geol Eng 38, 683–694 (2020). https://doi.org/10.1007/s10706-019-01057-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-019-01057-y