Abstract

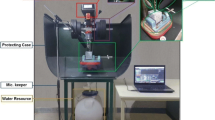

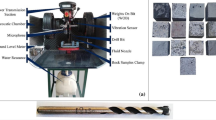

The drilling process is one of the significant stages of rock mechanic and mining engineering. Monitoring this operation can help researchers to have accurate perspective about drilling process, physical and mechanical features of rocks and drill bit characteristics. Drilling operation generates acoustic signals as an unwanted byproduct, which could be helpful for analyzing the nature of this process. Determining the features of rock has an undeniable importance in all downstream steps of designation in mining projects. Definition of rock properties by using direct measurement tests is a time-consuming and costly process and requires high precision. Development a novel frequency based method in this research, for determining physical and rock-mechanical features of rock could be helpful for solving problems of time consumption, cost, and precision. None of the direct and indirect conventional methods is able, to provide an accessible and efficient way (in the viewpoint of cost, time consumption, and precision) for accelerating this process. This study attempts to present mathematical relations between rock mass features and dominant acoustic frequencies emitted during drilling process using Fast Fourier Transform (FFT). A novel rotary drilling machine, with the ability to record acoustic frequencies, is designed and constructed by investigators for providing this goal. All influencing parameters of drilling regime (vertical thrust force, drill bit rotational speed, diameter and material of drill bit, sound recording ability etc.) are manageable using this machine. For drilling tests and determining physical and rock mechanical characteristics, 11 volcanic rock samples are gathered in a wide range of features. After drilling tests and by analyzing acoustic signals, five dominant frequencies are extracted for each sample. Results demonstrate almost all physical–mechanical properties of volcanic rocks (uniaxial compressive strength, tensile strength, S and P-wave velocity, porosity percentage and Schmidt Rebound Number) are predictable using diverse dominant frequencies of acoustic signals. Overall, the results present novel linear models, which are able to predict rock features.

Similar content being viewed by others

References

Byerlee J (1978) Friction of rocks. Pure Appl Geophys 116(4–5):615–626

Flegner P, Kačur J, Durdán M, Leššo I, Laciak M (2014) Measurement and processing of vibro-acoustic signal from the process of rock disintegration by rotary drilling. Measurement 56:178–193

Gradl C, Eustes AW, Thonhauser G (2008) An analysis of noise characteristics of drill bits. In: ASME 2008 27th international conference on offshore mechanics and arctic engineering, 2008. American Society of Mechanical Engineers, pp 681–687

Gradl C, Eustes AW, Thonhauser G (2012) An analysis of noise characteristics of drill bits. J Energy Res Technol 134(1):013103

Hardy HR (1972) Application of acoustic emission techniques to rock mechanics research. In: Acoustic emission. ASTM International, West Conshohocken, A.A. Balkema publishers

Hatherly P (2002) Rock strength assessment from geophysical logging. In: Proceedings of the 8th international symposium on borehole geophysics for minerals, geotechnical and groundwater applications, Toronto, Ontario, Canada

Hsu K-L, Gao X, Sorooshian S, Gupta HV (1997) Precipitation estimation from remotely sensed information using artificial neural networks. J Appl Meteorol 36(9):1176–1190

Kivade SB, Murthy CSN, Vardhan H (2015) ANN models for prediction of sound and penetration rate in percussive drilling. J Inst Eng India Ser D 96(2):93–103

Knill J, Franklin J, Malone A (1968) A study of acoustic emission from stressed rock. Int J Rock Mech Min Sci Geomech Abstr 5(1):87–88

Kostur K, Futo J (2007) Optimization of rock disintegration based on acoustic background of drilling machine. Mech AGH Univ Sci Technol 26(1):1–7

Kumar BR, Vardhan H, Govindaraj M (2010) Estimating rock properties using sound level during drilling: field investigation. Int J Min Miner Eng 2(3):169–184

Kumar BR, Vardhan H, Govindaraj M (2011a) Sound level produced during rock drilling vis-à-vis rock properties. Eng Geol 123(4):333–337

Kumar BR, Vardhan H, Govindaraj M (2011b) Prediction of uniaxial compressive strength, tensile strength and porosity of sedimentary rocks using sound level produced during rotary drilling. Rock Mech Rock Eng 44(5):613–620

Marceau J, Moji Y (1973) Application of fracture mechanics testing to process control for adhesive bonding. Document D6–41145, Boeing Commercial Airplane Company

McNally G (1990) The prediction of geotechnical rock properties from sonic and neutron logs. Explor Geophys 21(1/2):65–71

Miklusova V, Usalova L, Ivanicova L, Krepelka F (2006) Acoustic signal-new feature in monitoring of rock disintegration process. Contrib Geophys Geod 36:125–133

Obert L (1941) Use of subaudible noises for prediction of rock bursts. US Department of the Interior, Bureau of Mines, Washington

Obert L, Duvall W (1942) Use of subaudible noises for the prediction of rock bursts, part II. US Bur Mines Rep 4:365

Roy S, Adhikari G (2007) Worker noise exposures from diesel and electric surface coal mining machinery. Noise Control Eng J 55(5):434–437

Vardhan H, Bayar RK (2013) Rock engineering design: properties and applications of sound level. CRC Press, Boca Raton

Vardhan H, Murthy CS (2007) An experimental investigation of jack hammer drill noise with special emphasis on drilling in rocks of different compressive strengths. Noise Control Eng J 55(3):282–293

Vardhan H, Adhikari G, Raj MG (2009) Estimating rock properties using sound levels produced during drilling. Int J Rock Mech Min Sci 46(3):604–612

Ward B (1998) German Creek Mines Rock strength from velocity logs. Unpublished report for Capricorn Coal Management Pty Ltd

Williams E, Hagan P (2006) Monitoring acoustic emission levels with changes in rock cutting conditions. Pub, University of New South Wales, www.mining.unsw.edu.au/Publications/publications_staff/Paper_WilliamsHogan_AE_2006_web.htm. Accessed July 2006

Zang A, Wagner CF, Dresen G (1996) Acoustic emission, microstructure, and damage model of dry and wet sandstone stressed to failure. J Geophys Res Solid Earth 101(B8):17507–17521

Zborovjan M (2001) Identification of minerals during drilling process via acoustic signal. Metall Foundry 26:367–374

Zborovjan M, Lesso I, Dorcak L (2003) Acoustic identification of rocks during drilling process. J Acta Montan Slovaca 8(4):91–93

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yari, M., Bagherpour, R. Implementing Acoustic Frequency Analysis for Development the Novel Model of Determining Geomechanical Features of Igneous Rocks Using Rotary Drilling Device. Geotech Geol Eng 36, 1805–1816 (2018). https://doi.org/10.1007/s10706-017-0433-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-017-0433-3