Abstract

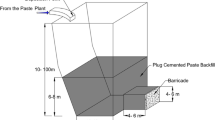

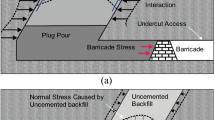

Paste backfill used to provide ground support in underground mining is generated from full-stream tailings and is almost always placed underground with cement. For the backfill, both the rate of strength development and the final strength are important considerations for design, particularly when the backfill is subsequently exposed in the stope-mining sequence. There is strong evidence that strengths measured on specimens obtained from coring the in situ cemented backfill are much greater than laboratory-cured specimens with the same cement content. The paper reviews some of the experimental evidence showing that one of the major reasons for the different strength is the difference in effective stress acting on the backfill during curing. Laboratory specimens are (almost) always cured under zero total stress, so no effective stress develops. In contrast, backfill in a stope may cure under high effective stress, which develops due to either “conventional” consolidation in free-draining backfills, or to the so-called “self-desiccation” mechanism in fine-grained fills. Evidence is presented showing how the final strength is affected by applying stress to specimens at different stages of curing and at different rates. It is shown that a fully-coupled analysis of the filling behaviour is required to determine the appropriate effective stress regime to apply in curing laboratory specimens, where “fully-coupled” in this context means taking account of the interaction of consolidation/drainage rate, filling rate and cement hydration rate. Curing protocols for laboratory specimens are proposed, which would ensure that the strengths obtained are representative of in situ conditions.

Similar content being viewed by others

Abbreviations

- C c :

-

Cement content: weight of dry cement per unit dry weight of solids (tailings and cement)

- c v :

-

Coefficient of consolidation

- K o :

-

Coefficient of earth pressure “at rest” (=σ′ h/σ′ v)

- q u :

-

Unconfined compressive strength

- ε a :

-

Axial strain

- σa :

-

Axial stress in an unconfined compression test

- σ b :

-

Stress on the barricade

- σh, σ′h :

-

Total and effective horizontal stress

- σv, σ′v :

-

Total and effective vertical stress

References

Belem T, Benzaazoua M, Bussière B, Dagenais AM (2002) Effects of settlement and drainage on strength development within mine paste backfill. Proceedings of the 9th international conference on tailings and mine waste, vail, fort collins, colorado, AA Balkema, Rotterdam, 139–148

Belem T, El Aatar O, Bussiere B, Benzaazoua M, Fall M, and Yilmaz E (2006) Characterisation of self-weight consolidated paste backfill. Proceedings of the international conference paste’06, Limerick, Ireland, 333–345

Blight GE, Spearing AJS (1996) The properties of cemented silicated backfill for use in narrow, hard-rock, tabular mines. J S Afr Inst Min Metall 96(1):17–28

Cayouette J (2003) Optimization of paste backfill plant at Louvicourt mine. Bull Can Inst Min Metall Petrol (CIM) 96(1075):51–57

Charles BJ (2009) The effect of stress application on the strength of cemented mine backfill. Final year undergraduate thesis, School of Civil & Resource Engineering, The University of Western Australia, Perth, Australia

Consoli NC, Rotta GV, Prietto PDM (2000) Influence of curing under stress on the triaxial response of cemented soils. Géotechnique 50(1):99–105

Dalla Rosa F, Consoli NC, Baudet BA (2008) Experimental investigation of the behaviour of artificially cemented soil cured under stress. Géotechnique 58(8):675–679

Fahey M, Helinski M, Fourie A (2010) Consolidation in accreting sediments: Gibson’s solution applied to backfilling of mine stopes. Géotechnique 60(11):877–882. doi:10.1680/geot.9.P.078

Fall M, Nasir O, Célestin J (2007) Paste backfill responses in deep mine temperature conditions. Minefill’07: Proceedings of the 9th international symposium on mining with backfill, Montreal, Paper # 2522 (published on CD only)

Gibson RE (1958) The progress of consolidation in a clay layer increasing in thickness with time. Géotechnique 8(4):171–183

Helinski M, Fahey M, Fourie A (2007a) Numerical modelling of cemented mine backfill deposition. J Geotech Geoenviron Eng ASCE 133(10):1308–1319

Helinski M, Fourie AB, Fahey M, Ismail M (2007b) The self desiccation process in cemented mine backfill. Can Geotech J 44(10):1148–1156

Helinski M, Fahey M, Fourie A (2010) Coupled two-dimensional finite element modelling of mine backfilling with cemented tailings. Can Geotech J 47(11):1187–1200. doi:10.1139/T10-020

Helinski M, Fahey M, Fourie A (2011a) Behaviour of cemented paste backfill in two mine stopes—measurements and modelling. J Geotech Geoenviron Eng ASCE. doi:10.1061/(ASCE)GT.1943-5606.0000418 (accepted 21 July 2010; to appear February 2011)

Helinski M, Fourie A, Fahey M (2011b) A framework for designing and managing cemented mine backfill. Proceedings of the 10th international conference on mining with backfill, Cape Town, South Africa, March 21–25

Le Roux KA, Bawden WF, Grabinski MWF (2002) Assessing the interaction between hydration rate and fill rate for a cemented paste backfill. Proceedings on the 55th Canadian geotechnical and 3rd joint IAH-CNC groundwater specialty conference, Niagara Falls, Ontario, 427–432

Page DT (2009) Damage to cement bonds during hydration of paste fill. Final year undergraduate thesis, School of Civil & Resource Engineering, The University of Western Australia, Perth, Australia

Potvin Y, Thomas E, Fourie A (2005) Handbook on mine fill. Australian Centre for Geomechanics. ISBN 0-9756756-2-1

Revell MB (2004) Paste—how strong is it? Proceedings of the 8th international symposium on mining with backfill, September, Beijing, The Nonferrous Metals Society of China, 286–294

Rotta GV, Consoli NC, Prietto PDM, Coop MR, Graham J (2003) Isotropic yielding in an artificially cemented soil cured under stress. Géotechnique 53(5):493–501

Simms P, Grabinski M (2009) Direct measurement of matric suction in triaxial tests on early-age cemented paste backfill. Can Geotech J 46(1):93–101

Acknowledgments

The authors wish to thank the project sponsors Panoramic Resources, Barrick, and BHP Billiton for their support of this research. Financial support for the first author for his PhD work at UWA was provided by the UWA Gledden Postgraduate Scholarships Foundation, the Shaw Memorial Postgraduate Scholarship Foundation, and MERIWA (the Minerals and Energy Research Institute of Western Australia) for their financial contribution to this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fahey, M., Helinski, M. & Fourie, A. Development of Specimen Curing Procedures that Account for the Influence of Effective Stress During Curing on the Strength of Cemented Mine Backfill. Geotech Geol Eng 29, 709–723 (2011). https://doi.org/10.1007/s10706-011-9412-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-011-9412-2