Abstract

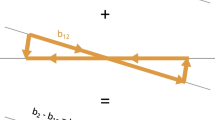

A interaction model between discrete dislocation emission and the grain boundary at the crack tip of microscale grain is described. When the dislocation emission condition is satisfied, dislocations will be emitted from the crack tip and will move along a slip plane to the grain boundary. Dislocations will pile at the grain boundary and create stress concentration. At this time dislocation penetration and crack nucleation at the grain boundary may occur. The distribution and penetration of dislocations at the crack tip will have a new effect on the crack. In this paper, different grain boundary angles and grain sizes are studied to find the relationship between dislocations and cracks. The results show that the main crack tends to propagate in large grain boundary angle and in small grain size crystalline materials. And wedge crack in the grain boundary tends to initiate with large grain boundary angle and in large grain size crystalline materials.

Similar content being viewed by others

References

Bilby BA, Swinden AHCH (1963) The spread of plastic yield from a Notch. Proc R Soc Lond 272(1350):304–314. https://doi.org/10.1098/rspa.1963.0055

Chang S, Ohr SM (1981) Dislocation-free zone model of fracture. J Appl Phys 52(12):7174–7181

Cotterill RMJ (1977) Does dislocation density have a natural limit? Phys Lett A 60(1):61–62

Dai S, Li JCM (1982) Dislocation-free zone at the crack tip. Scr Metall 16(2):183–188

Das ESP, Marcinkowski MJ (1972) Accommodation of the stress field at a grain boundary under heterogeneous shear by initiation of microcracks. J Appl Phys 43(11):4425–4434

Fedorov AA, Gutkin MY, Ovid’ko IA (2003) Transformations of grain boundary dislocation pile-ups in nano- and polycrystalline materials. Acta Mater 51(4):887–898

Hirth JP (1983) Theory of dislocations, 2nd edn. Wiley, New York

Kacher J, Robertson IM (2012) Quasi-four-dimensional analysis of dislocation interactions with grain boundaries in 304 stainless steel. Acta Mater 60(19):6657–6672

Kobayashi S, Ohr SM (1980) In situ fracture experiments in b.c.c metals. Philos Mag A 42(6):763–772

Kobayashi S, Ohr SM (1981) In-situ observations of the formation of plastic zone ahead of a crack tip in copper. Scr Metall 15(3):343–348

Kumar KS, Swygenhoven HV, Suresh S (2003) Mechanical behavior of nanocrystalline metals and alloys. Acta Mater 51(19):5743–5774

Lee D, Vermilyea DA (1971) The initiation of intergranular failure in inconel-600. Metall Trans 2(9):2565–2571

Lee TC, Robertson IM, Birnbaum HK (1990) TEM in situ deformation study of the interaction of lattice dislocations with grain boundaries in metals. Philos Mag A 62(1):131–153

Li Z, Hou C, Huang M et al (2009) Strengthening mechanism in micro-polycrystals with penetrable grain boundaries by discrete dislocation dynamics simulation and Hall-Petch effect. Comput Mater Sci 46(4):1124–1134. https://doi.org/10.1016/j.commatsci.2009.05.021

Lin IH, Thomson R (1986) Cleavage, dislocation emission, and shielding for cracks under general loading. Acta Metall 34(2):187–206

Ma M, Kang S, Zhang H, et al (2015) First-principle study on hydrogen embrittlement phenomenon of α-Fe. Hot Work Technol

Mara NA, Sergueeva AV, Mara TD et al (2007) Superplasticity and cooperative grain boundary sliding in nanocrystalline Ni3Al. Mater Sci Eng A 463(1–2):238–244. https://doi.org/10.1016/j.msea.2006.08.123

Meyers MA (2009) Mechanical behavior of materials, 2nd edn. Cambridge University Press, Cambridge

Miller KJ (1987) The behaviour of short fatigue cracks and their initiation part II—a general summary. Fatigue Fract Eng Mater Struct 10(2):93–113. https://doi.org/10.1111/j.1460-2695.1987.tb01153.x

Ohr SM (1985) An electron microscope study of crack tip deformation and its impact on the dislocation theory of fracture. Mater Sci Eng 72(1):1–35. https://doi.org/10.1016/0025-5416(85)90064-3

Ovid’ko IA, Sheinerman AG (2004) Triple junction nanocracks in deformed nanocrystalline materials. Acta Mater 52(5):1201–1209

Ovidko IA, Sheinerman AG (2009) Grain size effect on crack blunting in nanocrystalline materials. Scr Mater 60(8):627–630

Ovid’ko IA, Sheinerman AG (2010) Ductile vs. brittle behavior of pre-cracked nanocrystalline and ultrafine-grained materials. Acta Mater 58(16):5286–5294

Ran F, Long QY, Zhang TY et al (1989) Cleavage crack-tip deformation in single-crystal zinc. J Phys D 22(7):991

Shen Z, Wagoner RH, Clark WAT (1986) Dislocation pile-up and grain boundary interactions in 304 stainless steel. Scr Metall 20(6):921–926

Shen Z, Wagoner RH, Clark WAT (1988) Dislocation and grain boundary interactions in metals. Acta Metall 36(12):3231–3242

Smith E, Barnby JT (1967) Crack nucleation in crystalline solids. Metal Sci Journal 1(1):56–64. https://doi.org/10.1179/msc.1967.1.1.56

Suresh S (1998) Fatigue of materials, 2nd edn. Cambridge University Press, Cambridge

Wang L, Teng J, Liu P et al (2014) Grain rotation mediated by grain boundary dislocations in nanocrystalline platinum. Nat Commun 5:4402

Acknowledgements

The work is supported by the National Natural Science Foundation of China (11472230).

Funding

The work is supported by the National Natural Science Foundation of China (11472230).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sheng, Y., Yang, H., Ma, W. et al. Interaction of dislocations and cracks in grains based on discrete dislocations. Int J Fract 239, 135–147 (2023). https://doi.org/10.1007/s10704-022-00668-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-022-00668-6