Abstract

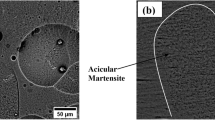

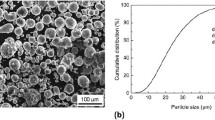

Al–Mg–Sc–Zr alloys manufactured using selective laser melting (SLM) possess outstanding static mechanical properties and thus have great potential application in the aerospace industry. However, their fatigue performance has not been clearly investigated and understood. In this work, the high cycle fatigue properties of an Al–Mg–Sc–Zr alloy manufactured via SLM with optimised process parameters (relative density over 99%) was studied with focus on the defects, whose size, shape and distribution were determined through X-ray tomography. Microstructure analysis results show that the Al–Mg–Sc–Zr alloy produced using SLM presents a periodic, inhomogeneous structure consisting of equiaxed grains at the boundary and columnar grains at the centre of one molten pool, which causes a significant difference in deformational mismatch under the fabrication conditions. Furthermore, X ray-CT results show that the defects, mainly porosity, are randomly distributed with the critical flaw size to initiate fatigue crack, thereby reducing fatigue life. When the stress ratio (R) is 0.1, the annealed sample presents good fatigue strength (σf) reaching 100.5 MPa, which is close to that of high-strength wrought 7075Al. Finally, a fatigue crack propagation mode connected with defect microstructure characteristics was established for prediction of fatigue properties.

Similar content being viewed by others

References

Aboulkhair NT, Simonelli M, Parry L et al (2019) 3D printing of aluminium alloys: additive Manufacturing of aluminium alloys using selective laser melting. Prog Mater Sci 106:100578

Balachandramurthi AR, Moverare J, Dixit N, Pederson R (2018) Influence of defects and as-built surface roughness on fatigue properties of additively manufactured Alloy 718. Mater Sci Eng A 735:463–474

Bayoumy D, Schliephake D, Dietrich S et al (2021) Intensive processing optimization for achieving strong and ductile Al-Mn-Mg-Sc-Zr alloy produced by selective laser melting. Mater Des 198:15–17

Beretta S, Romano S (2017) A comparison of fatigue strength sensitivity to defects for materials manufactured by AM or traditional processes. Int J Fatigue 94:178–191

Bi J, Lei Z, Chen Y et al (2020) Densification, microstructure and mechanical properties of an Al-14.1Mg-0.47Si-0.31Sc-0.17Zr alloy printed by selective laser melting. Mater Sci Eng A 774:138931

Brandl E, Heckenberger U, Holzinger V, Buchbinder D (2012) Additive manufactured AlSi10Mg samples using selective laser melting (SLM): microstructure, high cycle fatigue, and fracture behavior. Mater Des 34:159–169

Croteau JR, Griffiths S, Rossell MD et al (2018) Microstructure and mechanical properties of Al-Mg-Zr alloys processed by selective laser melting. Acta Mater 153:35–44

Galy C, Le Guen E, Lacoste E, Arvieu C (2018) Main defects observed in aluminum alloy parts produced by SLM: from causes to consequences. Addit Manuf 22:165–175

GB/T 3075–2008 (2008) Metal material axial loading fatigue test method. Metallic materials-tensile testing-part 1: method of test at room temperature. China National Standard GB/T 228.1–2010

Herzog D, Seyda V, Wycisk E, Emmelmann C (2016) Additive manufacturing of metals. Acta Mater 117:371–392

Jesus JS, Borrego LP, Ferreira JAM et al (2020) Fatigue crack growth behaviour in Ti6Al4V alloy specimens produced by selective laser melting. Int J Fract 223:123–133

Kitagawa H (1976) Applicability of fracture mechanics to very small cracks or the cracks in the early stage. In: Proceedings of the 2nd ICM 31

Kumar P, Ramamurty U (2020) High cycle fatigue in selective laser melted Ti-6Al-4V. Acta Mater 194:305–320

Liu F, He C, Chen Y et al (2020) Effects of defects on tensile and fatigue behaviors of selective laser melted titanium alloy in very high cycle regime. Int J Fatigue 140:105795

Murakami Y (1985) Analysis of stress intensity factors of modes I, II and III for inclined surface cracks of arbitrary shape. Stress Int J Biol Stress 22:101–114

Murakami Y (2002) Metal fatigue: effects of small defects and nonmetallic inclusions. Elsevier, London

Olakanmi EO, Cochrane RF, Dalgarno KW (2015) A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: processing, microstructure, and properties. Prog Mater Sci 74:401–477

Ren YM, Lin X, Guo PF et al (2019) Low cycle fatigue properties of Ti-6Al-4V alloy fabricated by high-power laser directed energy deposition. Exp Predict 127:58–73

Rometsch PA, Zhong H, Nairn KM et al (2014) Characterization of a laser-fabricated hypereutectic Al-Sc alloy bar. Scr Mater 87:13–16

Sanaei N, Fatemi A (2020) Defects in additive manufactured metals and their effect on fatigue performance: a state-of-the-art review. Prog Mater Sci 117:100724

Schmidtke K, Palm F, Hawkins A, Emmelmann C (2011) Process and mechanical properties: Applicability of a scandium modified Al-alloy for laser additive manufacturing. Phys Procedia 12:369–374

Shi Y, Yang K, Kairy SK, Palm F, Wu X, Rometsch PA (2018) Effect of platform temperature on the porosity, microstructure and mechanical properties of an Al–Mg–Sc–Zr alloy fabricated by selective laser melting. Mater Sci Eng A 732(May):41–52

Spierings AB, Dawson K, Dumitraschkewitz P et al (2018) Microstructure characterization of SLM-processed Al-Mg-Sc-Zr alloy in the heat treated and HIPed condition. Addit Manuf 20:173–181

Spierings AB, Dawson K, Heeling T et al (2017a) Microstructural features of Sc- and Zr-modified Al-Mg alloys processed by selective laser melting. Mater Des 115:52–63

Spierings AB, Dawson K, Kern K et al (2017b) SLM-processed Sc- and Zr- modified Al-Mg alloy: mechanical properties and microstructural effects of heat treatment. Mater Sci Eng A 701:264–273

Tang M, Pistorius PC (2017) Oxides, porosity and fatigue performance of AlSi10Mg parts produced by selective laser melting. Int J Fatigue 94:192–201

Tsukrov I, Kachanov M (1997) Stress concentrations and microfracturing patterns in a brittle-elastic solid with interacting pores of diverse shapes. Int J Solids Struct 34:2887–2904

Xie C, Wu S, Yu Y et al (2021) Defect-correlated fatigue resistance of additively manufactured Al-Mg4.5Mn alloy with in situ micro-rolling. J Mater Process Technol 291:117039

Wang P, Lei H, Zhu X et al (2019) Influence of manufacturing geometric defects on the mechanical properties of AlSi10Mg alloy fabricated by selective laser melting. J Alloys Compd 789:852–859

Wang Z, Lin X, Kang N et al (2020) Strength-ductility synergy of selective laser melted Al-Mg-Sc-Zr alloy with a heterogeneous grain structure. Addit Manuf 34:101260

Wang Z, Lin X, Kang N et al (2021) Laser powder bed fusion of high-strength Sc/Zr-modified Al–Mg alloy: phase selection, microstructural/mechanical heterogeneity, and tensile deformation behavior. J Mater Sci Technol 95:40–56

Yadollahi A, Shamsaei N (2017) Additive manufacturing of fatigue resistant materials: challenges and opportunities. Int J Fatigue 98:14–31

Yap CY, Chua CK, Dong ZL et al (2015) Review of selective laser melting: materials and applications. Appl Phys Rev 2:041101

Acknowledgements

This work was supported by National Key Research and Development Plan of China (2016YFB1100102) and National Natural Science Foundation of China (52005411) and the Research Fund of the State Key Laboratory of Solidification Processing (NPU) (2020-tz-02).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Qin, Z., Kang, N., Zhang, F. et al. Role of defects on the high cycle fatigue behavior of selective laser melted Al–Mg–Sc–Zr alloy. Int J Fract 235, 129–143 (2022). https://doi.org/10.1007/s10704-021-00593-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-021-00593-0