Abstract

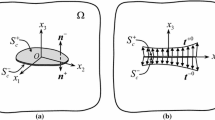

Theoretical and experimental studies have revealed that at small length scales, surface effects contribute significantly to overall elastic deformation. In this paper, we analyze a torsional problem for a nanosized penny-shaped crack in an infinite homogeneous isotropic elastic medium with surface elasticity on the boundary of the crack. The resulting model of deformation leads to a nonclassical mixed boundary value problem which is analyzed using the Hankel transform technique leading to a pair of dual integral equations. The latter are solved numerically with the solution demonstrating excellent convergence. We examine the contribution of surface elasticity by comparing the calculated torsional displacement and bulk stresses to their counterparts in the absence of surface elasticity. The influence of surface and bulk shear modulus on the torsional stress intensity factors is analyzed and displayed graphically. Our results show that stress intensity factors are dependent on both the crack size and the bulk/surface material properties, revealing that the presence of surface elasticity may hinder or promote crack growth, depending on whether the surface shear modulus takes positive or negative values. As a check, we also note that our results indeed reduce to the corresponding classical results in the absence of surface elasticity.

Similar content being viewed by others

References

Almasri AH, Voyiadjis GZ (2009) Nano-indentation in FCC metals: experimental study. Acta Mech 209(1):1–9

Cammarata RC (1994) Surface and interface stress effects in thin films. Prog Surf Sci 46(1):1–38

Charitidis Costas A, Dragatogiannis Dimitrios A (2013) Finite element analysis, stress strain distribution and size effects rise during nanoindentation of welded aluminum alloy. Inter J Struct Integr 4(1):78–90

Chen T, Chiu MS, Weng CN (2006) Derivation of the generalized Young–Laplace equation of curved interfaces in nanoscaled solids. J Appl Phys 100(7):074308

Chhapadia P, Mohammadi P, Sharma P (2011) Curvature-dependent surface energy and implications for nanostructures. J Mech Phys Solids 59(10):2103–2115

Dingreville R, Qu JM, Cherkaoui M (2005) Surface free energy and its effect on the elastic behavior of nano-sized particles, wires and films. J Mech Phys Solids 53(8):1827–1854

Eisner R (1955) Tensile tests on silicon whiskers. Acta Metall 3(4):414–415

Espinosa H (2004) Plasticity size effects in free-standing submicron polycrystalline FCC films subjected to pure tension. J Mech Phys Solids 52(3):667–689

Fu XL, Wang GF, Feng XQ (2010) Surface effects on mode-i crack tip fields: a numerical study. Eng Fract Mech 77(7):1048–1057

Gorbushin N, Eremeyev VA, Mishuris G (2020) On stress singularity near the tip of a crack with surface stresses. Int J Eng Sci 146:103183

Grekov MA, Yazovskaya AA (2014) The effect of surface elasticity and residual surface stress in an elastic body with an elliptic nanohole. J Appl Math Mech 78(2):172–180

Gurtin ME, Murdoch AI (1975) A continuum theory of elastic material surfaces. Arch Ration Mech Anal 57(4):291–323

Gurtin ME, Murdoch AI (1978) Surface stress in solids. Int J Solids Struct 14(6):431–440

Hirakata H, Nishijima O, Fukuhara N, Kondo T, Yonezu A, Minoshima K (2011) Size effect on fracture toughness of freestanding copper nano-films. Mater Sci Eng A 528(28):8120–8127

Hu ZL, Li XF (2018) A rigid line inclusion in an elastic film with surface elasticity. Z Angew Math Phys 69(4):92

Hu ZL, Lee KY, Li XF (2018) Crack in an elastic thin-film with surface effect. Int J Eng Sci 123:158–173

Hu ZL, Yang Y, Li XF (2021a) Bending fracture of ultra-thin plates with surface elasticity containing a thickness-through crack. Int J Solids Struct 226–227:111093

Hu ZL, Yang Y, Li XF (2021b) Singular elastic field induced by a rigid line inclusion in a thin nanoplate with surface elasticity. Int J Mech Sci 198:106386

Intarit P, Senjuntichai T, Rungamornrat J, Rajapakse RKND (2017) Penny-shaped crack in elastic medium with surface energy effects. Acta Mech 228(2):617–630

Kim CI, Schiavone P, Ru CQ (2011a) Analysis of plane-strain crack problems mode-I/mode-II in the presence of surface elasticity. J Elast 104(1):397–420

Kim CI, Schiavone P, Ru CQ (2011b) The effect of surface elasticity on a mode-III interface crack. Arch Mech 63(3):267–286

Kim W, Cho M (2010) Surface effect on the self-equilibrium state and size-dependent elasticity of FCC thin films. Modell Simul Mater Sci Eng 18(8):085006

Kim YC, Gwak EJ, Ahn SM, Jang JI, Han HN, Kim JY (2017) Indentation size effect in nanoporous gold. Acta Mater 138:52–60

Lee C, Wei X, Kysar JW, Hone J (2008) Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 321(5887):385–388

Li XF (2019) Effect of surface elasticity on stress intensity factors near mode-III crack tips. J Mech Mater Struct 14(1):43–60

Magnus W, Oberhettinger F, Soni RP (1966) Formulas and theorems for the special functions of mathematical physics. Springer, Berlin

Meyer J, Paillet M, Roth S (2005) Materials science: single-molecule torsional pendulum. Science 309:1539–1541

Miller RE, Shenoy VB (2000) Size-dependent elastic properties of nanosized structural elements. Nanotechnology 11(3):139–147

Nguyen T, Rungamornrat J, Senjuntichai T, Wijeyewickrema A (2015) FEM-SGBEM coupling for modeling of mode-I planar cracks in three-dimensional elastic media with residual surface tension effects. Eng Anal Bound Elem 55:40–51

On BB, Altus E, Tadmor EB (2010) Surface effects in non-uniform nanobeams: continuum vs. atomistic modeling. Int J Solids Struct 47(9):1243–1252

Pearson G, Read W, Feldmann W (1957) Deformation and fracture of small silicon crystals. Acta Metall 5(4):181–191

Saxena HS, Dhaliwal RS, He W, Rokne JG (1993) Penny-shaped interface crack between dissimilar nonhomogeneous elastic layers under axially symmetric torsion. Acta Mech 99:201–211

Shodja HM, Enzevaee C (2019) Surface characterization of face-centered cubic crystals. Mech Mater 129:15–22

Sylwestrowicz WD (1962) Mechanical properties of single crystals of silicon. Philos Mag 7(83):1825–1845

Tada Hiroshi, Paris Paul C, Irwin George R (1973) The stress analysis of cracks handbook. ASME Press, New York

Walton JR (2012) A note on fracture models incorporating surface elasticity. J Elast 109(1):95–102

Wang X (2015) A mode III arc-shaped crack with surface elasticity. Z Angew Math Phys 66(4):1987–2000

Wang X, Schiavone P (2016) Bridged cracks of mode III with surface elasticity. Mech Mater 95:125–135

Wu CH (1999) The effect of surface stress on the configurational equilibrium of voids and cracks. J Mech Phys Solids 47:2469–2492

Xu JY, Dong CY (2016) Surface and interface stress effects on the interaction of nano-inclusions and nano-cracks in an infinite domain under anti-plane shear. Int J Mech Sci 111:12–23

Yang Y, Lee KY, Li XF (2018) Surface effects on delamination of a thin film bonded to an elastic substrate. Int J Fract 210(1–2):81–94

Yang Y, Hu ZL, Li XF (2020) Nanoscale mode-III interface crack in a bimaterial with surface elasticity. Mech Mater 140:103246

Zhang T, Li X, Gao H (2015) Fracture of graphene: a review. Int J Fract 196(1–2):1–31

Acknowledgements

This work was supported by the National Natural Science Foundation of China under Grant Nos. 12072374 and 11672336 and the Natural Science Foundation of Hunan Province under Grant No. 2020JJ4106. Gharahi and Schiavone thank the Natural Sciences and Engineering Research Council of Canada for support via a Discovery Grant (Grant No: RGPIN - 2017 - 03716115112). Yang acknowledges the State Scholarship Fund from the China Scholarship Council (CSC).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, Y., Hu, ZL., Gharahi, A. et al. Torsion of an elastic medium containing a nanosized penny-shaped crack with surface effects. Int J Fract 231, 189–199 (2021). https://doi.org/10.1007/s10704-021-00575-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-021-00575-2