Abstract

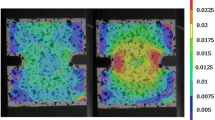

The effect of transformation-induced plasticity (TRIP) on the fracture response of polycrystalline shape memory alloys is analyzed in the prototype infinite center-cracked plate subjected to thermal cycling under constant mechanical loading in plain strain. Finite element calculations are carried out to determine the mechanical fields and the crack-tip energy release rate using the virtual crack closure technique. Similar to phase transformation, TRIP is found to affect both the driving force for crack growth and the crack growth kinetics by promoting crack advance when occurring in a fan in front of the crack tip and providing a “shielding” effect when occurring behind that fan. Accumulation of TRIP strains over the cycles results in higher energy release rates from one cycle to another and may result in crack growth if the crack-tip energy release rate reaches a material “specific” critical value after a sufficient number of cycles. During crack advance, the shielding effect of the TRIP strains left in the wake of the growing crack dominates and therefore TRIP is found to both promote the initiation of crack growth and extend the stable crack growth regime.

Similar content being viewed by others

References

Abaqus (2015) Analysis user’s, manual. Dassault Systèmes of America Corp, Woodlands Hills

Ardakani S, Hatefi AH, Mohammadi S (2015) Thermo-mechanically coupled fracture analysis of shape memory alloys using the extended finite element method. Smart Mater Struct 24:045031

Baxevanis T, Lagoudas DC (2012) A mode I fracture analysis of a center-cracked infinite shape memory alloy plate under plane stress. Int J Fract 175(2):151–166

Baxevanis T, Chemisky Y, Lagoudas DC (2012) Finite element analysis of the plane-strain crack-tip mechanical fields in pseudoelastic shape memory alloys. Smart Mater Struct 21(9):094012

Baxevanis T, Landis CM, Lagoudas DC (2013a) On the fracture toughness of pseudoelastic shape memory alloys. J Appl Mech 81(4):041005

Baxevanis T, Parrinello AF, Lagoudas DC (2013b) On the fracture toughness enhancement due to stress-induced phase transformation in shape memory alloys. Int J Plast 50:158–169

Baxevanis T, Landis CM, Lagoudas DC (2014) On the effect of latent heat on the fracture toughness of pseudoelastic shape memory alloys. J Appl Mech 81(10):101006

Baxevanis T, Parrinello AF, Lagoudas DC (2016) On the driving force for crack growth during thermal actuation of shape memory alloys. J Mech Phys Solids 89:255–271

Birman V (1998) On mode I fracture of shape memory alloy plates. Smart Mater Struct 7:433–437

Bo Z, Lagoudas DC (1999a) Thermomechanical modeling of polycrystalline SMAs under cyclic loading, Part II: material characterization and experimental results for a stable transformation cycle. Int J Eng Sci 37:1141–1173

Bo Z, Lagoudas DC (1999b) Thermomechanical modeling of polycrystalline SMAs under cyclic loading, Part III: evolution of plastic strains and two-way shape memory effect. Int J Eng Sci 37:1175–1203

Bo Z, Lagoudas DC (1999c) Thermomechanical modeling of polycrystalline SMAs under cyclic loading, Part IV: modeling of minor hysteresis loops. Int J Eng Sci 37:1205–1249

Bo Z, Lagoudas DC (1999d) Thermomechanical modeling of polycrystalline SMAs under cyclic loading, Part I: theoretical derivations. Int J Eng Sci 37:1089–1140

Boyd J, Lagoudas DC (1996) A thermodynamical constitutive model for shape memory materials, Part I: the monolithic shape memory alloy. Int J Plast 12(6):805–842

Budiansky B, Hutchinson JW, Lambropoulos JC (1983) Continuum theory of dilatant transformation toughening in ceramics. Int J Solids Struct 19(4):337–355

Cherkaoui M, Berveiller M, Sabar H (1998) Micromechanical modeling of martensitic transformation induced plasticity (TRIP) in austenitic single crystals. Int J Plast 14:597–626

Creuziger A, Bartol LJ, Gall K, Crone W (2008) Fracture in single crystal NiTi. J Mech Phys Solids 56:2896–2905

Daly S, Miller A, Ravichandar G, Bhattacharya K (2007) An experimental investigation of crack initiation in thin sheets of nitinol. Acta Mater 55:6322–6330

Daymond MR, Young ML, Almer JD, Dunand DC (2007) Strain and texture evolution during mechanical loading of a crack tip in martensitic shape-memory NiTi. Acta Mater 55:3929–3942

Desindes S, Daly S (2010) The small-scale yielding of shape memory alloys under mode III fracture. Int J Solids Struct 47:730–737

Entchev P, Lagoudas DC (2004) Modeling of transformation-induced plasticity and its effect on the behavior of porous shape memory alloys, Part I: constitutive model for fully dense SMAs. Mech Mater 36:865–892

Fischer F, Reisner G, Werner K, Tanaka E, Cailletaud T, Antretter G (2000) A new view on transformation induced plasticity (TRIP). Int J Plast 16:723–748

Freed Y, Banks-Sills L (2007) Crack growth resistance of shape memory alloys by means of a cohesive zone model. J Mech Phys Solids 55:2157–2180

Gall K, Yang N, Sehitoglu H, Chumlyakov Y (2001) Fracture of precipitated NiTi shape memory alloys. Int J Fract 109:189–207

Gollerthan S, Young ML, Baruj A, Frenzel J, Schmahl WW, Eggeler G (2009) Fracture mechanics and microstructure in NiTi shape memory alloys. Acta Mater 57:1015–1025

Hartl DJ, Lagoudas DC (2007) Aerospace applications of shape memory alloys. In: Proceedings of the institution of mechanical engineers. Part G: journal of aerospace engineering, SAGE pp 535–552

Hazar S, Zaki W, Moumni Z, Anlas G (2015) Modeling of steady-state crack growth in shape memory alloys using a stationary method. Int J Plast 67:26–39

Iliopoulos AP, Steuben JC, Kirk T, Baxevanis T, Michopoulos JG, Lagoudas DC, Thermomechanical failure response of notched NiTi coupons. Int J Solids Struct–In Press

Irwin GR (1958) Handbuch der Physik VI. Spinger, Berlin, pp 558–590 Ch. Fracture I

Jape S, Baxevanis T, Lagoudas DC (2014) Stable crack growth during actuation in shape memory alloys. In: SPIE smart structures and materials + nondestructive evaluation and health monitoring. International Society for Optics and Photonics pp 905802(1–9)

Jape S, Baxevanis T, Lagoudas DC (2016) Stable crack growth during thermal actuation of shape memory alloys. Shape Memory Superelast 2:104113

Jape S, Baxevanis T, Parrinello AF, Lagoudas DC (2015) On the fracture response of shape memory alloy actuators. In: Proceedings of the TMS middle east: Mediterranean materials congress on energy and infrastructure systems (MEMA 2015). Wiley, pp 165–180

Krueger R (2004) Virtual crack closure technique: History, approach, and applications. Appl Mech Rev 57(2):109–143

Kumar PK, Lagoudas DC (2008) Shape memory alloys: modeling and engineering applications. Springer, New-York, pp 1–51 Ch. Introduction to Shape Memory Alloys

Lambropoulos JC (1986) Shear, shape and orientation effects in transformation toughening. Int J Solids Struct 22:1083–1106

Lexcellent C, Laydi MR, Taillebot V (2011) Analytical prediction of the phase transformation onset zone at a crack tip of a shape memory alloy exhibiting asymmetry between tension and compression. Int J Fract 169(1):1–13

Liu Y, McCormick P (1994) Thermodynamic analysis of the martensitic transformation in Ti-Ni-I, effect of heat treatment on transformation behaviour. Acta Metall Mater 42:2401–2406

Maletta C, Furgiuele F (2010) Analytical modeling of stress-induced martensitic transformation in the crack tip region of nickel-titanium alloys. Acta Mater 58:92–101

Maletta C, Furgiuele F (2011) Fracture control parameters for NiTi based shape memory alloys. Int J Solids Struct 48:1658–1664

Maletta C, Sgambitterra E, Fabrizio N (2016) Temperature dependent fracture properties of shape memory alloys: novel findings and a comprehensive model. Sci Rep 6:1–11

Nespoli A, Besseghini S, Pittaccio S, Villa E, Viscuso S (2010) The high potential of shape memory alloys in developing miniature mechanical devices: a review on shape memory alloy mini-actuators. Sens Actuators, A 158(1):149–160

Perkins J, Bobowiec P (1986) Microstructural effects of martensitic transformation cycling of a Cu–Zn–Al alloy: vestigial structures in the parent phase. Metall Trans A 17A:195–203

Robertson SW, Metha A, Pelton AR, Ritchie RO (2007) Evolution of crack-tip transformation zones in superelastic Nitinol subjected to in situ fatigue: a fracture mechanics and synchrotron X-ray micro-diffraction analysis. Acta Mater 55:6198–6207

Rybicki E, Kanninen M (1977) A finite element calculation of stress intensity factors by a modified crack closure integral. Eng Fract Mech 9:931–938

Sreekumar M, Nagarajan T, Singaperumal M, Zoppi M, Molfino R (2007) Critical review of current trends in shape memory alloy actuators for intelligent robots. Ind Robot 34(4):285–294

Stam G, van der Giessen E (1995) Effect of reversible phase transformations on crack growth. Mech Mater 21:51–71

Ungár T, Frenzel J, Gollerthan S, Ribárik G, Balogh L, Eggeler G, (2017) On the competition between the stress-induced formation of martensite and dislocation plasticity during crack propagation in pseudoelastic NiTi shape memory alloys. J Mater Res 1–10. doi:10.1557/jmr.2017.267

Wang XM, Wang YF, Baruj A, Eggeler G, Yue ZF (2005) On the formation of martensite in front of cracks in pseudoelastic shape memory alloys. Mater Sci Eng A 394:393–398

Xie D, Biggers S (2006) Progressive crack growth analysis using interface element based on the virtual crack closure technique. Finite Elem Anal Des 42:977–984

Yan W, Mai Y (2006) IUTAM symposium on mechanics and reliability of actuating materials. Springer, Berlin, pp 217–226 Ch. Theoretical Consideration on the Fracture of Shape Memory Alloys

Yi S, Gao S (2000) Fracture toughening mechanism of shape memory alloys due to martensite transformation. Int J Solids Struct 37:5315–5327

Yi S, Gao S, Shen L (2001) Fracture toughening mechanism of shape memory alloys under mixed-mode loading due to martensite transformation. Int J Solids Struct 38:4463–4476

Acknowledgements

This material is based upon work supported by the Air Force Office of Scientific Research under Grant Number FA9550-15-1-0287.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jape, S., Baxevanis, T. & Lagoudas, D.C. On the fracture toughness and stable crack growth in shape memory alloy actuators in the presence of transformation-induced plasticity. Int J Fract 209, 117–130 (2018). https://doi.org/10.1007/s10704-017-0245-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-017-0245-8