Abstract

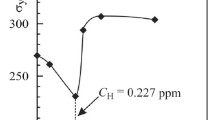

The shock response of anti-hydrogen steel (HR-2) and iron was studied in a series of laser-driven shock wave experiments. A line-imaging optical recording velocity interferometer system for any reflector was used to record the free surface velocity histories of shock loaded samples, 100–300 \(\upmu \hbox {m}\) thick and with an initial temperature ranging from 296 to 1073 K. Based on the recorded free surface velocity profiles, the elastic precursors, dynamic yield and tensile (spall) strengths of HR-2 and iron were calculated. The dependence of the measured HEL stresses on the propagation distance for HR-2 and polycrystalline iron is approximated by a power law relationship.But, that for the single crystal iron with orientation of (110) seems to be constant. Spall strengths \((\upsigma _{\mathrm{sp}})\) of HR-2 estimated from the magnitude of the pull-back signal show that the spall strength dependence on the strain rate \((\dot{\upvarepsilon })\) is approximated by a power law relationship \(\upsigma _{\mathrm{sp}} =0.24\left( \dot{\upvarepsilon } \right) ^{0.24}\,\left( {\hbox {GPa}} \right) \). The spall strength of HR-2 and single crystal iron at the initial temperatures of 296–1073 K decreases slightly with increasing temperature and that of poly crystal iron abnormally increases at a temperature of 873 K. The X-ray diffraction results on the recovered poly crystal samples indicate significant changes in the relative peak intensity and the change in the crystal orientation may be the reason for the abnormal increasing at 873 K. The spall fracture surfaces of HR-2 were observed using a 3D laser scanning confocal microscope. The spall surface contains many dimples, suggesting that the fracture mode is that of ductile fracture. At ambient temperatures, the dimples and crowns were evenly distributed at the fracture surface. At high temperatures, many large crowns appeared and were unevenly distributed at the fracture surface.

Similar content being viewed by others

References

Antoun T, Seaman L, Curran D, Kanel GI, Razorenov SV, Utkin AV (2002) Spall fracture. Springer, New-York

Ashitkov SI, Agranat MB, Kanel GI, Komarov PS, Fortov VE (2010) Behavior of aluminum near an ultimate theoretical strength in experiments with femtosecond laser pulses. JETP Lett 92(8):516–520

Celliers PM, Bradley DK, Collins GW, Hicks DG, Boehly TR, Armstrong WJ (2004) Line-imaging velocimeter for shock diagnostics at the OMEGA laser facility. Rev Sci Instrum 75:4916–4929

Crowhurst JC, Armstrong MR, Knight KB, Zaug JM, Behymer EM (2011) Invariance of the dissipative action at ultrahigh strain rates above the strong shock threshold. Phys Rev Lett 107:144302-1–144302-5

de Ress’eguier T, Hallouin M (2008) Effects of the alpha–epsilon phase transition on wave propagation and spallation in laser shock-loaded iron. Phys Rev B 77:174107-1–174107-7

de Ress’eguier T, Lescoute E, Loison D (2012) Influence of elevated temperature on the wave propagation and spallation in laser shock-loaded iron. Phys Rev B 86:214102-1–214102-7

Deng XM, Liang XC, Chen Z (1986) Uniform illumination of large targets using a lens array. Appl Opt 25:377–381

Gahagan KT, Moore DS, Funk DJ, Rabie RL, Buelow SJ, Nicholson JW (2000) Measurement of shock wave rise times in metal thin films. Phys Rev Lett 85:3205–3208

Germann TC, Tanguy D, Holian BL, Lomdahl PS, Mareschal M, Ravelo R (2004) Dislocation structure behind a shock front in fcc perfect crystals: atomistic simulation results. Metall Mater Trans A 35:2609–2615

Gu ZW, Jin XG, Gao GQ (2000) Shock response of stainless steel at high temperature. J Mat Sci 35:2347–2351

Huang SH, Jin XG (1994) In: Proceedings of the conference on shock waves in condensed matter, p. 1083

Kanel GI (2012) Rate and temperature effects on the flow stress and tensile strength of metals. AIP Conf Proc 1426:939–944

Kanel GI, Razorenov SV, Utkin AV, Fortov VE (1996) Shock-wave phenomena in condensed matter. Yanus-K, Moscow (in Russian)

Kanel GI, Razorenov SV, Garkushin GV, Ashitkov SI, Komarov PS, Agranat MB (2014) Deformation resistance and fracture of iron over a wide strain rate range. Phys Solid State 56(8):1569–1573

Kuksin AY, Stegailov VV, Yanikin AV (2008) Molecular-dynamics simulation of edge-dislocation dynamics in aluminum. Dokl Phys 53(6):287–291

Li J, Ngan AHW, Gumbsch P (2003) Atomistic modeling of mechanical behavior. Acta Mater 51:5711–5742

Olmsted DL, Hecto LG, Curtin WA, Clifton RJ (2005) Atomistic simulations of dislocation mobility in Al, Ni and Al/Mg alloys Model. Simul Mater Sci Eng 13:371–388

Razorenov SV, Kanel GI, Fortov VE (2004) Iron at high negative pressures. JETP Lett 80:348–350

Shu H, Fu SZ, Huang XG, Wu J, Zhou HZ, Ye JJ (2012) A modified illumination system for a line-imaging optically recording velocity interferometer and its application in equation of state measurement. Meas Sci Technol 23:015203-1–015203-5

Shu H, Fu SZ, Huang XG, Dong JQ, Fang ZH, Wang T, Ye JJ, Xie ZY, Guo J, Zhou HZ (2013) A joint diagnostic system for laser-driven shock wave experiments. Eur Phys J Appl Phys 62(3):31001-1–31001-4

Shu H, Fu SZ, Huang XG, Pan H, Zhang F, Xie ZY, Ye JJ, Jia G (2014) Plastic behavior of aluminum in high strain rate regime. J Appl Phys 116:033506-1–033506-6

Whitley VH, McGrane SD, Eakins DE, Bolme CA, Moore DS, Bingert JF (2011) The elastic–plastic response of aluminum films to ultrafast laser-generated shocks. J Appl Phys 109:013505-1–013505-4

Wise JL, Mikkola DE (1988) In: Proceedings of the conference on shock waves in condensed Matter, p. 261

Zaretsky EB, Kanel GI (2012) Effect of temperature, strain, and strain rate on the flow stress of aluminum under shock-wave compression. J Appl Phys 112:073504-1–073504-9

Zaretsky EB, Kanel GI (2013) Response of copper to shock-wave loading at temperatures up to the melting point. J Appl Phys 114:083511-1–083511-11

Zaretsky EB, Kanel GI (2015) Yield stress, polymorphic transformation, and spall fracture of shock-loaded iron in various structural states and at various temperatures. J Appl Phys 117:195901-1–195901-10

Zhakhovsky VV, Budzevich MM, Inogamov NA, Oleynik II, White CT (2011) Two-zone elastic–plastic single shock waves in solids. Phys Rev Lett 107:135502-1–135502-4

Acknowledgements

This work has been supported by 863 National High-tech Plan of the People’s Republic of China. Also, the authors gratefully acknowledge the valuable support during the experiments by the “Shenguang-II” technical crews.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shu, H., Huang, X., Pan, H. et al. Plastic behavior of steel and iron in high strain rate regime. Int J Fract 206, 81–93 (2017). https://doi.org/10.1007/s10704-017-0202-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-017-0202-6