Abstract

An analytic model has been developed for a Compact Tension specimen subjected to a controlled displacement and corresponding load within a cohesive model framework. The model is able to capture the material response while the Fracture Process Zone is being developed, obtaining the evolution of multiple variables such as the crack opening and the cohesive stresses, for an arbitrary Cohesive Law shape. The crack growth prediction based on the \({\mathcal {R}}\)-curve and the nominal strength prediction based on Bažant’s Size Effect Law have been implemented using the output variables available from the proposed analytic model. The minimum specimen size has been found in order to properly apply \({\mathcal {R}}\)-curve based methods. The study has concluded that only the cohesive model is able to properly capture the changes of the Specimen Geometry and Specimen Size, as unlike in other theories, no Linear Elastic Fracture Mechanics assumptions are made.

Similar content being viewed by others

References

Andersson T, Stigh U (2004) The stress-elongation relation for an adhesive layer loaded in peel using equilibrium of energetic forces. Int J Solids Struct 41:413–434

ASTM (1997) E399-90, Standard test method for plane-strain fracture toughness of metallic materials. In: 1991 Annual book of ASTM standards, vol 3, pp 451–485 (Reapproved)

ASTM (1999) D5045–99. Standard test methods for plane-strain fracture toughness and strain energy release rate of plastic materials. ASTM, West Conshohocken

ASTM (2001) ASTM E1820–01. American society for testing and materials, standard test method for measurement of fracture toughness. American Society for Testing and Materials, West Conshohocken

ASTM (2006) ASTM E399–06e2. Standard test method for linear-elastic plane-strain fracture toughness \({K}_{Ic}\) of metallic materials. ASTM International, West Conshohocken, PA. doi:10.1520/E0399-06E02

Bao G, Suo Z (1992) Remarks on crack-bridging concepts. Appl Mech Rev 45(8):355–366

Barenblatt GI (1959) The formation of equilibrium cracks during brittle fracture: general ideas an hypotheses, axially-symmetric cracks. J Appl Math Mech 23:622–636

Barenblatt GI (1962a) The mathematical theory of equilibrium cracks in brittle fracture. Adv Appl Mech 7:55–129

Barenblatt GI (1962b) The mathematical theory of equilibrium cracks in brittle fracture. Adv Appl Mech 7:55–129

Bažant ZP (1985) Comment on Hillerborg’s size effect law and fictitious crack model. In: Cedolin L (ed) Dei Poli Anniversary Volume, Politecnico di Milano, pp 335–338

Bažant ZP (1992) Fracture mechnaics of concrete. In: First international conference on fracture mechanics of concrete structures

Bažant ZP (1997) Scaling of quasibrittle fracture: asymptotic analysis. Int J Fract 83:19–40

Bažant ZP, Oh BH (1983) Deformation of cracked net-reinforced concrete walls. J Struct Eng 109(2):93–108

Bažant ZP, Planas J (1998) Fracture and size effect in concrete and other quasibrittle materials. CRC Press, Boca Raton, London

Bažant ZP, Kim J-K, Pfeiffer P (1985) Continuum model for progressive cracking and identification of nonlinear fracture parameters. In: Shah SP (ed) Application of fracture mechanics to cementitious composites. Martinus Nijhoff Publishers, Dordrecht, pp 197–246

Bergan AC, Dávila CG, Leone FA, Awerbuch J, Tan TM (2014) Mode I cohesive law characterization of through-crack propagation in a multidirectional laminate. In: Proceedings of the American society for composites 2014-twenty-ninth technical conference on composite materials

Bloyer DR, Venkateswara Rao KT, Ritchie RO (1998) Fracture toughness and R-curve behavior of laminated brittle-matrix composites. Metall Mater Trans A Phys Metall Mater Sci 29(10):2483–2496

Bolzon G, Fedele R, Maier G (2002) Parameter identification of a cohesive crack model by Kalman filter. Comput Methods Appl Mech Eng 191(25–26):2847–2871

Bouville F, Maire E, Meille S, Van de Moortèle B, Stevenson AJ, Deville S (2014) Strong, tough and stiff bioinspired ceramics from brittle constituents. Nat Mater 13(5):508–514

Brocks W, Cornec a, Scheider I (2002) Computational aspects of nonlinear fracture mechanics. GKSS Forschungszentrum—technical note (July), pp 2–187

Catalanotti G, Camanho PP, Xavier J, Dávila C, Marques A (2010) Measurement of resistance curves in the longitudinal failure of composites using digital image correlation. Compos Sci Technol 70(13):1986–1993

Demetriou MD, Launey ME, Garrett G, Schramm JP, Hofmann DC, Johnson WL, Ritchie RO (2011) A damage-tolerant glass. Nat Mater 10(2):123–128

Dugdale D (1960) Yielding of steel sheets containing slits. J Mech Phys Solids 8:100–104

Elices M, Planas J (1993) The equivalent elastic crack: 1. Load-Y equivalences. Int J Fract 61(2):159–172

Elices M, Guinea GV, Gómez J, Planas J (2002) The cohesive zone model: advantages, limitations and challenges. Eng Fract Mech 69(2):137–163

Gutkin R, Laffan ML, Pinho ST, Robinson P, Curtis PT (2011) Modelling the R-curve effect and its specimen-dependence. Int J Solids Struct 48(11–12):1767–1777

Hillerborg A, Modéer M, Petersson PE (1976) Analysis of crack formation and crack growth in concrete by means of fracture mechanics and finite elements. Cem Concr Res 6:773–781

Irwin GR (1960) Fracture mechanics. In: Goodier N, Hoff NJ (eds) Structural mechanics. Pergamon Press, London

Jacobsen TK, Sørensen BF (2001) Mode I intra-laminar crack growth in composites modelling of R-curves from measured bridging laws. Compos Part A Appl Sci Manuf 32:1–11

Koester KJ, Ager JW, Ritchie RO (2008a) The effect of aging on crack-growth resistance and toughening mechanisms in human dentin. Biomaterials 29:1318–1328

Koester KJ, Ager JW, Ritchie RO (2008b) The true toughness of human cortical bone measured with realistically short cracks. Nat Mater 7(8):672–677

Krafft JM, Sullivan AM, Boyle RW (1961) Effect of dimensions of fast fracture instability of notched sheets. In: Proceedings of cranfield crack propagation symposium, pp 8–28

Mai YW (2006) Cohesive zone and crack-resistance (R)-curve of cementitious materials and their fibre-reinforced composites. Eng Fract Mech 69(2002):219–234

Mai YW, Hakeem MI (1984) Slow crack growth in bleached cellulose fibre cements. J Mater Sci Lett 3(2):127–130

Maimí P, Trias D, González E, Renart J (2012) Nominal strength of quasi-brittle open hole specimens. Compos Sci Technol 72(10):1203–1208

Maimí P, González EV, Gascons N, Ripoll L (2013) Size effect law and critical distance theories to predict the nominal strength of quasibrittle structures. Appl Mech Rev 65:1–16

Mall S, Newman JC (1985) The Dugdale model for compact specimen. In: Fracture mechanics: sixteenth symposium, pp 113–128

Naglieri V, Gludovatz B, Tomsia AP, Ritchie RO (2015) Developing strength and toughness in bio-inspired silicon carbide hybrid materials containing a compliant phase. Acta Mater 98:141–151

Newman C Jr (1983) A nonlinear fracture mechanics approach to the growth of small cracks In: Zocher H (ed) Behaviour of short cracks in airframe components, AGARD CP-328. pp 6.1–6.26

Newman J, Yamada Y, James MA (2010) Stress-intensity-factor equations for compact specimen subjected to concentrated forces. Eng Fract Mech 77(6):1025–1029

Olsson P, Stigh U (1989) On the determination of the constitutive properties of thin interphase layers—an exact inverse solution. Int J Fract 41(1):71–76

Ortega A, Maimí P, González E, Ripoll L (2014) Compact tension specimen for orthotropic materials. Compos Part A Appl Sci Manuf 63:85–93

Ortega A, Maimí P, González EV (2015) Characterization of the intralaminar fracture cohesive law. In: 7th International conference on composite testing and model identification COMPTEST 2015

Ortega A, Maimí P, González EV, Trias D (2016) Characterization of the translaminar fracture cohesive law. Compos Part A Appl Sci Manuf 91:501–509

Ouyang C, Shah S (1993) Toughening mechanisms in quasi-brittle materials. J Eng Mater Technol 115:300

Paris AJ, Paris PC (1988) Instantaneous evaluation of J and C*. Int J Fract 38:19–21

Planas J, Elices M, Ruiz G (1993) The equivalent elastic crack: 2. X-Y equivalences and asymptotic analysis. Int J Fract 61:231–246

Que NS, Tin-Loi F (2002) An optimization approach for indirect identification of cohesive crack properties. Comput Struct 80:1383–1392

Rice JR (1968) A path independent integral and the approximate analysis of strain concentration by notches and cracks. ASME J Appl Mech 35(2):379–386

Ritchie RO (2011) The conflict between strength and toughness. Nat Mater 10:817–822

Roelfstra PE, Wittmann FH (1986) Numerical method to link strain softening with failure of concrete. In: Wittmann FH (ed) Fracture toughness and fracture energy of concrete. Elsevier Science Publishers, B. V., Amsterdam, pp 163–175

Silva FG, Xavier J, Pereira FA, Morais JJ, Dourado N, Moura MF (2014) Determination of cohesive laws in wood bonded joints under mode II loading using the ENF test. Int J Adhes Adhes 51(8):54–61

Sørensen BF, Jacobsen TK (1998) Large-scale bridging in composites: R-curves and bridging laws. Compos Part A Appl Sci Manuf 29(11):1443–1451

Sørensen BF, Jacobsen TK (2003) Determination of cohesive laws by the J integral approach. Eng Fract Mech 70:1841–1858

Sørensen BF, Jørgensen K, Jacobsen TK, Østergaard RC (2006) DCB-specimen loaded with uneven bending moments. Int J Fract 141:163–176

Sørensen BF, Gamstedt EK, Østergaard RC, Goutianos S (2008) Micromechanical model of cross-over fibre bridging—prediction of mixed mode bridging laws. Mech Mater 40(4–5):220–234

Steiger T, Sadouki H, Wittmann FH (1995) Simulation and observation of the fracture process zone. In: Proceedings of fracture mechanics of concrete structures, FRAMCOS II, vol II, pp 157–168

Suo Z, Bao G, Fan B (1992) Delamination R-curve phenomena due to damage. J Mech Phys Solids 40(1):1–16

Tada H, Paris PC, Irwin GR (2000) The stress analysis of cracks handbook. ASME Press, New York

Williams TN, Newman JC Jr, Gullett PM (2011) Crack-surface displacements for cracks emanating from a circular hole under various loading conditions. Fatigue Fract Eng Mater Struct 34(4):250–259

Yan J, Mecholsky JJ, Clifton KB (2007) How tough is bone? Application of elastic-plastic fracture mechanics to bone. Bone 40(2):479–484

Zobeiry N, Vaziri R, Poursartip A (2014) Characterization of strain-softening behaviour and failure mechanisms of composites under tension and compression. Compos Part A Appl Sci Manuf 68:29–41

Acknowledgements

This work has been partially funded by the Spanish Government through the Ministerio de Economía y Competitividad, under contracts MAT2013-46749-R (subprogram MAT) and MAT2015-69491-C3-1-R.

Author information

Authors and Affiliations

Corresponding author

Additional information

Daniel Trias: Serra Húnter Fellow.

Appendices

Appendix 1: Stress intensity factors equations

The Stress Intensity Factor \(\bar{K}^P\) due the load P is defined (Tada et al. 2000)

The Stress Intensity Factor \(K_i^Q\) due a point load Q at a distance of \(\bar{a}_i\) measured from the load line, positioned at the crack surface, is defined (Newman et al. 2010)

The non-dimensional stress intensity factor \(\bar{K}_i^\sigma \) caused by a constant cohesive stress of normalized width \(\varDelta \bar{a}\) and centered at \(a_i\) (Mall and Newman 1985):

The crack opening at a distance \(\bar{a}_i\) caused by the load P is obtained

The crack opening at a distance \(\bar{a}_i\) caused by a constant cohesive stress of normalized length \(\varDelta \bar{a}\) and centred at \(\bar{a}_j\) is obtained

Appendix 2: Elastic CT compliance

The dimensionless elastic compliance for an isotropic material is defined (Tada et al. 2000)

Appendix 3: Cohesive solution extended for orthotropic materials

The differential equation that defines the stress state of an orthotropic material with the principal directions aligned normal to the crack growth direction depends on the roots of the polynomial (Ortega et al. 2014):

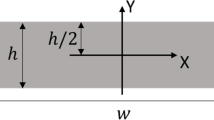

Defining the principal directions as in Fig. 2, in the plane stress case, \(\lambda \) and \(\rho \) are expressed as:

where \(E_{11}\) and \(E_{22}\) are the elastic moduli, \(G_{12}\) is the shear modulus, and \(\nu _{12}\) is the Poisson’s ratio. In the plane strain case, \(\lambda \) and \(\rho \) are obtained by replacing \(E_{11}\), \(E_{22}\) and \(\nu _{12}\) in Eq. (31) by:

To ensure the positive definiteness of the strain energy, it must be ensured that:

The anisotropy of the material is easily described by the parameters \(\lambda \) and \(\rho \). For an isotropic material, the parameters take the values \(\lambda =\rho =1\). However, for a cubic material, it only needs to be ensured that \(\lambda =1\) and that \(\rho \ne 1\).

In order to solve the cohesive model for an orthotropic material, the SIF, and therefore, the other variables defined in Sect. 2 need to be expressed as a function of the geometry, \(\lambda \) and \(\rho \).

The equation \(\bar{K}^P\left( \bar{a},\lambda ,\rho \right) \) is found in Ortega et al. (2014), as for the rest of the Eqs. 34 and 35, they can be obtained using the finite elements or equivalent method.

Rights and permissions

About this article

Cite this article

Ortega, A., Maimí, P., González, E.V. et al. Specimen geometry and specimen size dependence of the \({\mathcal {R}}\)-curve and the size effect law from a cohesive model point of view. Int J Fract 205, 239–254 (2017). https://doi.org/10.1007/s10704-017-0195-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-017-0195-1