Abstract

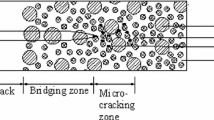

The mechanical reason for rock and concrete failure is trans-scale fracture, which can be divided into three phases: (1) microcrack evolution, (2) macrocrack nucleation, (3) macrocrack growth and run-through. Using the idea that a microcrack could be regarded as a well-organized aggregation of nucleated microdefects, the size growth model of the largest microcrack based on the accumulated number of microdefect nucleation is established. In order to test the validity of the model, trans-scale fracture of a plate made of heterogeneous material is numerically simulated to display the microcrack’s evolution. Statistical analysis of the number and sizes of the microcracks indicates that the predicted size of the largest microcrack according to the model is in close agreement with the measured crack size prior to peak stress, but not at all close to the measured values after the peak. At the end of the paper, some remaining problems are proposed for the further work.

Similar content being viewed by others

References

Ashby MF, Hallam SD (1986) The failure of brittle solids containing small cracks under compressive stress states [J]. Acta Metall 34(3):497–510

Bai YL, Ke FJ, Xia MF (1991) Formulation of statistical evolution of microcracks in solids. Acta Mech Sin 23(3):290–298

Carpinteri A, Chiaia B, Cornetti P (2003) On the mechanics of quasi-brittle materials with a fractal microstructure. Eng Fract Mech 70:2321–2349

Currau DR, Seaman L, Shockey DA (1987) Dynamic failure of solids Phys Rept 147(5–6):253–388

Horii H, Nemat-Nasser S (1986) Brittle failure in compression: splitting, faulting and brittle-ductile transition. Philos Trans R Soc Lond Ser A Math Phys Sci 319(1549):337–374

Huang JF, Chen GL, Zhao YH (1990) An experimental study of the strain field development prior to failure of a marble plate under compression[J]. Tectonhpysics 175:269–284

Kawakata H, Cho A, Yanagidani T et al (1997) The observations of faulting in Westerly granite under triaxial compression by X-ray CT scan. Int J Rock Mech Min Sci 34(3–4):151–162

Ke FJ, Bai YL, Xia MF (1990) The evolution characteristics of the ideal microcracks system[J]. China Sci 40(6):621–631

Kemeny JM, (1991) The micromechanics of deformation and failure in rocks. In: Proceedings of the International symposium on assessment and prevention of failure phenomena in rock engineering, Balkema, Rotterdam, pp 23–33

Lei X, Masuda K, Nishizawa O et al (2004) Detailed analysis of acoustic emission activity during catastrophic fracture of faults in rock[J]. J Struct Geol 26(2):247–258

Li L, Tsui Y, Lee PKK et al (2001) Progressive cracking of granite plate under uniaxial compression [J]. Chin J Rock Mech Eng 21(7):940–947

Li SY, He TM, Yin XC (2010) Introduction of rock fracture mechanics. China Science and Technology University Press, Hefei

Lockner DA, Byerlee JD, Kuksenko V et al (1991) Quasi-static fault growth and shear fracture energy in granite [J]. Nature 350:39–42

Meyer D, Van Mier JGM (2007) Influence of different PVA fibres on the crack behavious of foamed cement paste. In: Carpinteri A, Gambarova P, Ferro G, Plizzari G (eds) Proceedings of sixth international conference on ‘fracture mechanics of concrete structures’. Taylor & Francis Group/Balkema, Catania, Italy, London, pp 1359–1365

Niu ZR, Shi XJ (1992) Statistical theory of rock fractal fracture. Acta Feophys Sin 35(5):595–603

Park CH, Bobet A (2010) Crack initiation, propagation and coalescence from frictional flaws in uniaxial compression [J]. Eng Fract Mech 77:2727–2748

Peng CB, Chen Y (1989) On the fractal structure of earthquakes. Earthq Res China 5(2):19–26

Ponomarev AV, Zavyalov AD, Smirnov VB et al (1997) Physical modelingof the formation and evolution of seismically active fault zones [J]. Tectonophysics 277:57–81

Sammis CG, Ashby MF (1986) The failure of brittle porous solids under compressive stress states. Acta Metall 34(3):511–526

Shah SG, Chandra Kishen JM (2012) Use of acoustic emission in flexural faituge crack growth studies on concrete[J]. Eng Fract Mech (87):36–47

Shi C, Jiang XX, Zhu Z et al (2011) Study of rock damage constitutive model and discussion of its parameters based on Hoek-Brown criterion. Chin J Rock Mech Eng 30(s1):2647–2652

Silva FE, Goncalve LL, Fereira DBB et al (2005) Characterization of failure mechanism in composite materials through fractal analysis of acoustic emission signals [J]. Chaos Solitons Fractals 26(2):481–494

Simha KRY, Fourney WL, Barker DB et al (1986) Dynamic photoelastic investigation of two pressyrized cracks approaching one another. Eng Fract Mech 23(1):237–249

Van Mier JGM (2008) Framework for a generalized four-stage fracture model of cement-based materials [J]. Eng Fract Mech 75:5072–5086

Vilhelm J, Rudajev V, Lokajicek T et al (2008) Application of autocorrelation analysis for interpreting acoustic emission in rock[J]. Rock Mech Min Sci 45(7):1068–1081

Wang JA, Xie HP, Tian XY et al (1999) Direct fractal measurement of fracture surfaces. J Univ Sci Technol Beijing 21(3):6–9

Wang Li, Li SB (2011) Numerical simulation of damage pattern growth in quasi-brittle materials. Eng Mech 28(4):238–245

Xia MF, Ke FJ, Lv YH et al (1991) The effect of random growth in ideal microcracks system[J]. China Sci 23(3):276–284

Xie HP, Chen ZD (1988) Fractal geometry and fracture of rock. Acta Mech Sin 20(3):264–271

Xie HP, Gao F (1991) The fractal features of the damage evolution of rock materials. Chin J Rock Mech Eng 10(1):74–82

Xie HP, Feng ZG, Chen ZD (1999) On star product fractal surfaces and their dimensions. Appl Math Mech 20(11):1101–1106

Xie HP, Liu JF, Ju F et al (2011) Fractal property of spatial distribution of acoustic emission during the failure process of bedded rock salt [J]. Int J Rock Mech Min Sci 48(8):1344–1351

Xing XS (1986) Nonequilibrium statistical theory of brittle fracture. Eng Fract Mech 24:45

Zhang M, Lu YJ, Yang Q (2010) Failure probability and strength size effect of quasi-brittle materials. Chin J Rock Mech Eng 29(9):1782–1789

Zhou HW, Xie HP, Kwasniewski MA (2000) Fractal dimension of rough surface estimated by the cubic covering method. Tribology 20(6):445–455

Acknowledgments

The authors express their deep sense of gratitude to the anonymous reviewers who helped in bringing this paper to its current form. The work in this paper was supported by the National Natural Science Foundation of China (41172317/D0218) and the Foundation of Henan provincial Key Discipline of Engineering Mechanics.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, L., Ye, J., Mao, Y. et al. Microcracks size growth prediction based on microdefects nucleation number. Int J Fract 182, 239–249 (2013). https://doi.org/10.1007/s10704-013-9870-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-013-9870-z