Abstract

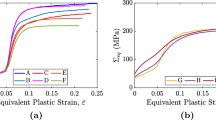

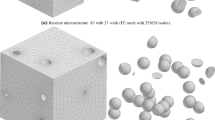

The fracture of porous ductile materials subjected to simple shear loading is numerically investigated using three-dimensional unit cells containing voids of various shapes and lengths of the inter-void ligament (void spacing). In shear loading, the porosity reduction is minimal while the void rotates and elongates within the shear band. The strain at coalescence was revealed to be strongly related to the initial void spacing and void shape. It is observed that a transitional spacing ratio for shear coalescence exists with coalescence being unlikely at spacing ratios lower than 0.35. Initially prolate voids are particularly prone to shear coalescence while initially oblate (flat) voids are most resistant to shear failure. The cell geometry becomes sensitive to shear coalescence for increasing void aspect and spacing ratios. In addition, the macroscopic shear stress response becomes independent of the void shape at high spacing ratios while showing a weak dependence on the void shape when the voids are far apart.

Similar content being viewed by others

References

ABAQUS version 6.10 (2010) User’s Manual, Hibbit, Karlsson & Sorensen, Inc., Providence (RI,US)

Barsoum I, Faleskog J (2007) Rupture mechanisms in combined tension and shear-micromechanics. Int J Solids Struct 44: 5481–5498

Benzerga AA (2002) Micromechanics of coalescence in ductile fracture. J Mech Phys Solids 50: 1331–1362

Brocks W, Sun DZ, Hon̈ig A (1995) Verification of the transferability of micromechanical parameters by cell model calculations with visco plastic materials. Int J Plast 11: 971–989

Butcher C, Chen ZT (2009) A void coalescence model for combined tension and shear. Model Simul Mater Sci Eng 17: 1–15

Danas K (2008) Porous materials with evolving microstructure: constitutive modeling, numerical implementation and applications. PhD Thesis, École Poletechnique, France

Fleck NA, Hutchinson JW (1986) Void growth in shear. Proc R Soc A 407: 435–458

Gao X, Kim J (2006) Modeling of ductile fracture: significance of void coalescence. Int J Solids Struct 43: 6277–6293

Gologanu M, Leblond J, Perrrin G, Devaus J (1997) Recent extensions of Gurson’s model for porous ductile metals. In: Suquet P (ed) Continuum micromechanics, CISM lectures series. Springer, New York, pp 61–130

Gurson AL (1977) Continuum theory of ductile rupture by void nucleation and growth—Part I. Yield criteria and flow rules for porous ductile media. J Eng Mater Technol 99: 2–15

Kaisalam M, Ponte Castañeda P (1998) A general constitutive theory for linear and nonlinear particulate media with microstructure evolution. J Mech Phys Solids 46: 427–465

Koplik J, Needleman A (1988) Void growth and coalescence in porous plastic solids. Int J Solids Struct 24: 835–853

Kuna M, Sun DZ (1996) Three-dimensional cell model analyses of void growth in ductile materials. Int J Fract 81: 235–258

Lassance D, Scheyvaerts F, Pardoen T (2006) Growth and coalescence of penny-shaped voids in metallic alloys. Eng Fract Mech 73: 1009–1034

Leblond JB, Mottet G (2008) A theoretical approach of strain localization within thin planer bands in porous ductile materials. Comptes Rendus Mécanique 336: 176–189

McClintock FA, Kaplan SM, Berg CA (1966) Ductile fracture by hole growth in shear bands. Int J Fract 2: 614–627

McVeigh C, Vernerey F, Liu WK, Moran B, Olson G (2007) An interactive micro-void shear localization mechanism in high strength steels. J Mech Phys Solids 55: 225–244

Nahshon K, Hutchinson JW (2008) Modification of the Gurson model for shear failure. Eur J Mech A Solids 27: 1–17

Pardoen T, Hutchinson JW (2000) An extended model for void growth and coalescence. J Mech Phys Solids 48: 2467–2512

Scheyvaerts F (2009) Multiscale modeling of ductile fracture in heterogeneous metallic alloys. Ph.D. Thesis, Université catholique de Louvain

Scheyvaerts F, Onck P, Pardoen T (2010) A new model for void coalescence by internal necking. Int J Damage Mech 19: 95–126

Scheyvaerts F, Onck P, Tekog̃lu C, Pardoen T (2011) The growth and coalescence of ellipsoidal voids in plane strain under combined shear and tension. J Mech Phys Solids 59: 373–397

Tekog̃lu C, Leblond JB, Pardoen T (2012) A criterion for the onset of void coalescence under combined tension and shear. J Mech Phys Solids 60: 1363–1381

Thomason P (1990) Ductile fracture of metals, 1st edn. Pergamon Press, Oxford

Tvergaard V (1981) Influence of voids on shear band instabilites under plane strain conditions. Intern J Fract 17: 389–407

Tvergaard V (2008) Shear deformation of voids with contact modelled by internal pressure. Int J Mech Sci 50: 1459–1465

Tvergaard V, Nielsen KL (2010) Relations between a micro-mechanical model and a damage model for ductile failure in shear. J Mech Phys Solids 58: 1243–1252

Worswick MJ, Pick RJ (1990) Void growth and constitutive softening in a periodically voided solid. J Mech Phys Solids 38: 601–625

Xue L (2007) Constitutive modeling of void shearing effect in ductile fracture of porous materials. Eng Fract Mech 75: 3343–3366

Zhang KS, Bai JB, François D (2001) Numerical analysis of the influence of the Lode parameter on void growth. Int J Solids Struct 38: 5836–5847

Zhang ZL, Niemi E (1994) Analyzing ductile fracture using dual dilational constitutive equations. Fatigue Fract Eng Mater Struct 17: 695–707

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rahman, M.A., Butcher, C. & Chen, Z. Void evolution and coalescence in porous ductile materials in simple shear. Int J Fract 177, 129–139 (2012). https://doi.org/10.1007/s10704-012-9759-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-012-9759-2