Abstract

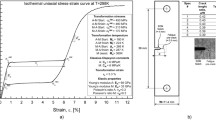

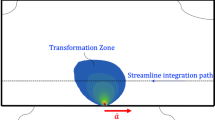

The high values of local stresses arising near the crack tip in Nickel–Titanium based shape memory alloys (SMAs) causes a stress-induced martensitic transformation. Previous studies have demonstrated that this micro-structural evolution plays a significant role in the fracture and fatigue properties of SMAs, as it significantly changes the crack tip stress distribution with respect to common engineering metals. In this investigation a novel analytical model is proposed, which is based on the small scale yielding condition and on modified elastic-plastic fracture mechanics concepts, to predict the extent of the crack tip transformation region together with the resulting stress distribution. In particular, based on the general framework of a recent literature approach, a new model has been developed in order to overcome one of the major limitation of the previous one, i.e. the assumption of constant stress during phase transformation. In fact, the proposed approach uses a trilinear stress–strain constitutive behavior, i.e. it is able to analyze SMAs with not constant transformation stress. The model has been applied to some case studies, in order to analyze the effects of several thermo-mechanical parameters and loading conditions on the crack tip transformation region and stress distribution.

Similar content being viewed by others

Abbreviations

- \({\sigma^{AM}_s}\) :

-

Martensite start stress

- \({\sigma^{AM}_f}\) :

-

Martensite finish stress

- \({\sigma^{MA}_s}\) :

-

Austenite start stress

- \({\sigma^{MA}_f}\) :

-

Austenite finish stress

- \({\varepsilon_L}\) :

-

Uniaxial transformation strain

- E A :

-

Young’s modulus of Austenite

- E M :

-

Young’s modulus of Martensite

- \({E_T=(\sigma^{AM}_f-\sigma^{AM}_s)/\varepsilon_L}\) :

-

Slope of the stress–strain transformation plateau

- α M = E M /E A :

-

Young’s modulus ratio

- α T = E T /E A :

-

Young’s modulus ratio

- ν :

-

Poisson ratio

- σ e :

-

Equivalent von-Mises stress

- σ ij :

-

Elastic stress component

- \({\varepsilon_{ij}}\) :

-

Elastic strain component

- S ij :

-

Deviatoric stress component

- δ ij :

-

Kronecker delta

- a :

-

Crack length

- a e :

-

Effective crack length

- σ ∞ :

-

Applied remote stress

- K I :

-

Mode I stress intensity factor (SIF)

- K Ie :

-

Effective mode I stress intensity factor

- σ Aij :

-

Stress component in the austenitic region

- σ Tij :

-

Stress component in the transformation region

- σ Mij :

-

Stress component in the martensitic region

- \({\varepsilon_{Aij}}\) :

-

Strain component in the austenitic region

- \({\varepsilon_{Tij}}\) :

-

Strain component in the transformation region

- \({\varepsilon_{Mij}}\) :

-

Strain component in the martensitic region

- r A :

-

Austenitic radius

- r M :

-

Martensitic radius

- r T :

-

Transformation radius

- b M :

-

Clausius–Clapeyron constant

- T :

-

Temperature

- (r, ϑ):

-

Polar coordinates

References

Baxevanis T, Lagoudas D (2012) A mode I fracture analysis of a center-cracked in niti shape memory alloy panel under plane stress. Int J Fract 175(2): 151–166

Birman V (1998) On mode I fracture of shape memory alloy plates. Smart Mater Struct 7(4): 433–437

Bouvet C, Calloch S, Lexcellent C (2004) A phenomenological model for pseudoelasticity of shape memory alloys under multiaxial proportional and nonproportional loadings. Eur J Mech A Solids 23: 37–61

Chen JH, Sun W, Wang GZ (2005) Investigation on the fracture behavior of shape memory alloy NiTi. Metall Mater Trans A Phys Metall Mater Sci 36(4): 941–955

Daly S, Miller A, Ravichandran G, Bhattacharya K (2007) An experimental investigation of crack initiation in thin sheets of Nitinol. Acta Mater 55: 6322–6330

Daymond MR, Young ML, Almer JD, Dunand DC (2007) Strain and texture evolution during mechanical loading of a crack tip in martensitic shape-memory NiTi. Acta Mater 55: 3929–3942

Dayananda GN, Rao MS (2008) Effect of strainrate on properties of superelastic NiTi thin wires. Mater Sci Eng A 486(1–2): 96–103

Desindes S, Daly S (2010) The small-scale yielding of shape memory alloys under mode III fracture. Int J Solids Struct 47: 730–737

Dugdale D (1960) Yielding of steel sheets containing slits. J Mech Phys Solids 8: 100

Duva JM (1998) Singularity at the apex of a rigid wedge embedded in a nonlinear material. J Appl Mech Trans ASME 55(2): 361–364

Freed Y, Banks-Sills L (2001) Crack growth resistance of shape memory alloys by means of a cohesive zone model. J Mech Phys Solids 55: 2157–2180

Gall K, Yang N, Sehitoglu H, Chumlyakov YI (2001) Fracture of precipitated NiTi shape memory alloys. Int J Fract 109(2): 189–207

Gall K, Tyber J, Wilkesanders G, Robertson SW, Ritchie RO, Maier HJ (2008) Effect of microstructure on the fatigue of hot-rolled and cold-drawn NiTi shape memory alloys. Mat Sci Eng A 486(1–2): 389–403

Gollerthan S, Herberg D, Baruj S, Eggeler G (2008) Compact tension testing of martensitic/pseudoplastic NiTi shape memory alloys. Materials Science and Engineering A 481–482(1–2): 156–159

Gollerthan S, Young ML, Baruj A, Frenzel J, Schmahl WW, Eggeler G (2009a) Fracture mechanics and microstructure in NiTi shape memory alloys. Acta Mater 57(4): 1015–1025

Gollerthan S, Young ML, Neuking K, Ramamurty U, Eggeler G (2009b) Direct physical evidence for the back transformation of stress-induced martensite in the vicinity of cracks in pseudoelastic NiTi shape memory alloys. Acta Mater 57: 5892–5897

Irwin GR (1960) Plastic zone near a crack and fracture toughness. In: Proceedings of seventh Sagamore Ordnance materials conference. Syracuse University Press, Syracuse, pp 63–78

Lexcellent C, Thiebaud F (2008) Determination of the phase transformation zone at a crack tip in a shape memory alloy exhibiting asymmetry between tension and compression. Scr Mat 59: 321–323

Lexcellent C, Laydi MR, Taillebot V (2011) Analytical prediction of the phase transformation onset zone at a crack tip of a shape memory alloy exhibiting asymmetry between tension and compression. Int J Fract 169(1): 1–13

Liu Y, Xiang H (1998) Apparent modulus of elasticity of near-equiatomic NiTi. J Alloys Compd 270: 154–159

Maletta C, Falvo A, Furgiuele F, Barbieri G, Brandizzi M (2009a) Fracture behaviour of nickel–titanium laser welded joints. J Mater Eng Perform 18(5–6): 569–574

Maletta C, Falvo A, Furgiuele F, Leonardi A (2009b) Stress-induced martensitic transformation in the crack tip region of a NiTi alloy. J Mater Eng Perform 18(5–6): 679–685

Maletta C, Furgiuele F (2010) Analytical modeling of stress-induced martensitic transformation in the crack tip region of nickeltitanium alloys. Acta Mater 58: 92–101

Maletta C, Furgiuele F (2011) Fracture control parameters for NiTi based shape memory alloys. Int J Solids Struct 48(11–12): 1658–1664

Maletta C, Young ML (2011) Stress-induced martensite in front of crack tips in NiTi shape memory alloys: modeling versus experiments. J Mat Eng Perform 20(4–5): 597–604

Nemat-Nasser S, Guo W-G (2006) Superelastic and cyclic response of NiTi SMA at various strain rates and temperatures. Mech Mater 38: 463–474

Otsuka K, Ren X (2005) Physical metallurgy of Ti-Ni-based shape memory alloys. Prog Mater Sci 50(5): 511–678

Otsuka K, Wayman CM (1998) Shape memory materials. Cambridge University Press, Cambridge

Paiva A, Savi MA (2006) An overview of constitutive models for shape memory alloys. Math Probl Eng, Article No. 56876

Rajagopalan S, Little AL, Bourke MAM, Vaidyanathan R (2005) Elastic modulus of shape-memory NiTi from in situ neutron diffraction during macroscopic loading, instrumented indentation, and extensometry. Appl Phys Lett 86(8) Article No. 081901

Raniecki B, Lexcellent C (1998) Thermodynamics of isotropic pseudoelasticity in shape memory alloys. Eur J Mech A Solids 17(2): 185–205

Robertson SW, Ritchie RO (2007) In vitro fatigue-crack growth and fracture toughness behavior of thin-walled superelastic Nitinol tube for endovascular stents: a basis for defining the effect of crack-like defects. Biomaterials 28(4): 700–709

Robertson SW, Ritchie RO (2008) A fracture-mechanics-based approach to fracture control in biomedical devices manufactured from superelastic nitinol tube. J Biomed Mater Res Part B Appl Biomater 84(1): 26–33

Robertson SW, Mehta A, Pelton AR, Ritchie RO (2007) Evolution of crack-tip transformation zones in superelastic Nitinol subjected to in situ fatigue: a fracture mechanics and synchrotron X-ray microdiffraction analysis. Acta Mater 55(18): 6198–6207

Wang GZ (2007) Effect of martensite transformation on fracture behavior of shape memory alloy NiTi in a notched specimen. Int J Fract 146(1–2): 93–104

Wang XM, Wang YF, Baruj A, Eggeler G, Yue ZF (2005) On the formation of martensite in front of cracks in pseudoelastic shape memory alloys. Mater Sci Eng A 394(1–2): 393– 398

Wang GZ, Xuan FZ, Tu ST, Wang ZD (2010) Effects of triaxial stress on martensite transformation, stressstrain and failure behavior in front of crack tips in shape memory alloy NiTi. Mater Sci Eng A 527: 1529–1536

Xiong F, Liu Y (2007) Effect of stress-induced martensitic transformation on the crack tip stress-intensity factor in Ni-Mn-Ga shape memory alloy. Acta Mater 55(16): 5621–5629

Yi S, Gao S (2000) Fracture toughening mechanism of shape memory alloys due to martensite transformation. Int J Solids Struct 37(38): 5315–5327

Yi S, Gao S, Shen L (2001) Fracture toughening mechanism of shape memory alloys under mixed-mode loading due to martensite transformation. Int J Solids Struct 38(24–25): 4463–4476

Young ML, Wagner MFX, Frenzel J, Schmahl WW, Eggeler G (2010) Phase volume fractions and strain measurements in an ultrafine-grained NiTi shape-memory alloy during tensile loading. Acta Mater 58: 2344–2354

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Maletta, C. A novel fracture mechanics approach for shape memory alloys with trilinear stress–strain behavior. Int J Fract 177, 39–51 (2012). https://doi.org/10.1007/s10704-012-9750-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-012-9750-y