Abstract

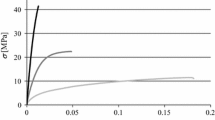

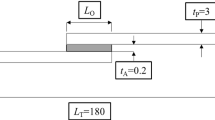

The failure of adhesively-bonded joints, consisting of metallic adherends and epoxy-based structural adhesive with a relatively low toughness ~200 J/m2, has been studied. The failure was via quasi-static mode I, steady-state crack propagation and has been modelled numerically. The model implements a ‘top-down approach’ to fracture using a dedicated steady-state, finite-element formulation. The damage mechanisms responsible for fracture are condensed onto a row of cohesive zone elements with zero thickness, and the responses of the bulk adhesive and of the adherends are represented by continuum elements spanning the full geometry of the joint. The material parameters employed in the model are first quantitatively identified for the particular epoxy adhesive of interest, and their validity is verified by comparison with experimental results. The model is then used to conduct a detailed study on the effects of (a) large variations in the geometrical configuration of the different types of specimens and (b) the adherend stiffness on the predicted value of the adhesive fracture energy, G a . These numerical modelling results reveal that the adhesive fracture energy is a strong nonlinear function of the thickness of the adhesive layer, the other variables being of secondary importance in influencing the value of G a providing the adhesive does not contribute significantly to the bending stiffness of the joint. These results which fully agree with experimental observations are explained in detail by identifying, and quantifying, the different sources of energy dissipation in the bulk adhesive contributing to the value of G a . These sources are the locked-in elastic energy, crack tip plasticity, reverse plastic loading and plastic shear deformation at the adhesive/adherend interface. Further, the magnitudes of these sources of energy dissipation are correlated to the degree of constraint at the crack tip, which is quantified by considering the opening angle of the cohesive zone at the crack tip.

Similar content being viewed by others

References

Bascom WD, Cottington RL, Jones RL, Peyser P (1975) The fracture of epoxy- and elastomer-modified epoxy polymers in bulk and as adhesives. J Appl Polym Sci 19: 2545–2562

Blackman BRK, Hadavinia H, Kinloch AJ, Paraschi M, Williams JG (2003a) The calculation of adhesive fracture energies in mode I: revisiting the tapered double cantilever beam (TDCB) test. Eng Fract Mech 70: 233–248

Blackman BRK, Hadavinia H, Kinloch AJ, Williams JG (2003b) The use of a cohesive zone model to study the fracture of fibre composites and adhesively-bonded joints. Int J Fract 119: 25–46

Blackman BRK, Kinloch AJ, Paraschi M, Teo WS (2003c) Measuring the mode I adhesive fracture energy, G IC , of structural adhesive joints: the results of an international round-robin. Int J Adhes Adhes 23: 293–305

Chai H (1986) Bond thickness effect in adhesive joints and its significance for mode I interlaminar fracture of composites. In: Composite materials testing and design, ASTM-STP 893, pp 209–231

Chai H (1988) Fracture work of thin bondline adhesive joints. J Mater Sci Lett 7: 399–401

Chai H, Chiang MYM (1998) Finite element analysis of interfacial crack propagation based on local shear, Part II—fracture. Int J Solids Struct 35: 815–829

Cooper V, Ivankovic A, Karac A, Murphy N (2009) The effect of constraint on the fracture toughness of adhesively bonded joints. In: Proceedings of the 32nd annual meeting of the Adhesion Society, Savannah, pp 33–35

Cui J, Wang R, Sinclair AN, Spelt JK (2003) A calibrated finite element model of adhesive peeling. Int J Adhes Adhes 23: 199–206

Dean RH, Hutchinson JW (1980) Quasi-static steady crack growth in small-scale yielding. In: Fracture mechanics, ASTM-STP 700, pp 383–405

Drugan WJ, Rice JR, Sham TL (1982) Asymptotic analysis of growing plane strain tensile cracks in elastic-ideally plastic solids. J Mech Phys Solids 30: 447–473

Ferracin T (2003) Mechanics of failure in adhesively bonded steel assemblies. PhD Thesis, Université catholique de Louvain, Belgium

Ferracin T, Landis CM, Delannay F, Pardoen T (2003) On the determination of the cohesive zone properties of an adhesive layer from the analysis of the wedge-peel test. Int J Solids Struct 40: 2889–2904

Hadavinia H, Kawashita L, Kinloch AJ, Moore DR, Williams JG (2006) A numerical analysis of the elastic-plastic peel test. Eng Fract Mech 73: 2324–2335

Hunston DL, Kinloch AJ, Wang SS (1989) Micromechanics of fracture in structural adhesive bonds. J. Adhes. 28: 103–114

Hutchinson JW, Evans AG (2000) Mechanics of materials: top-down approaches to fracture. Acta Mater 48: 125–135

Kafkalidis MS, Thouless MD, Yang QD, Ward SM (2000) Deformation and fracture of adhesive layers constrained by plastically-deforming adherends. J Adhes Sci Technol 14: 1593–1607

Kawashita LF, Moore DR, Williams JG (2008) The influence of bond line thickness and peel arm thickness on adhesive fracture toughness of rubber toughened epoxy-aluminium alloy laminates. Int J Adhes Adhes 28: 199–210

Kinloch AJ (1987) Adhesion and adhesives: science and technology, 1st edn. Chapman & Hall, London

Kinloch AJ, Shaw SJ (1981) The fracture resistance of a toughened epoxy adhesive. J Adhes 12: 59–77

Landis CM, Pardoen T, Hutchinson JW (2000) Crack velocity dependent toughness in rate dependent materials. Mech Mater 32: 663–678

Martiny Ph, Lani F, Kinloch AJ, Pardoen T (2008) Numerical analysis of the energy contributions in peel tests: a steady-state multilevel finite element approach. Int J Adhes Adhes 28: 222–236

McAuliffe D, Karac A, Murphy N, Ivankovic A (2011) Transferability of adhesive fracture toughness measurements between peel and TDCB test methods for a nano-toughened epoxy. In: Proceedings of the 34th annual meeting of the Adhesion Society, Savannah (USA)

Minamo (2010) Web page: http://www.cenaero.be/Minamo

Needleman A (1987) A continuum model for void nucleation by inclusion debonding. J Appl Mech 54: 525–531

Pardoen T, Marchal Y, Delannay F (1999) Thickness dependence of cracking resistance in thin aluminium plates. J Mech Phys Solids 47: 2093–2123

Pardoen T, Ferracin T, Landis CM, Delannay F (2005) Constraint effects in adhesive joint fracture. J Mech Phys Solids 53: 1951–1983

Rice JR (1967) Fatigue crack propagation. In: Fatigue crack propagation, ASTM-STP 415, p 247

Salomonsson K, Andersson T (2008) Modeling and parameter calibration of an adhesive layer at the meso level. Mech Mater 40: 48–65

Siegmund T, Brocks W (1998) Local fracture criteria: lengthscales and applications. In: Proceedings of the 2nd Euromech-Mecamat conference, Magdeburg, pp 347–354

Tvergaard V (1990) Effect of fiber debonding in a whisker-reinforced metal. Mater Sci Eng A 125: 203–213

Tvergaard V, Hutchinson JW (1992) The relation between crack growth resistance and fracture process parameters in elastic-plastic solids. J Mech Phys Solids 40: 1377–1397

Tvergaard V, Hutchinson JW (1994) Toughness of an interface along a thin ductile layer joining elastic solids. Phil Mag A 70: 641–656

Tvergaard V, Hutchinson JW (1996) Effect of strain-dependent cohesive zone model on predictions of crack growth resistance. Int J Solids Struct 33: 3297–3308

Wei Y, Hutchinson JW (1997) Nonlinear delamination mechanics for thin films. J Mech Phys Solids 45: 1137–1159

Yang QD, Thouless MD, Ward SM (1999) Numerical simulations of adhesively-bonded beams failing with extensive plastic deformation. J Mech Phys Solids 47: 1337–1353

Yang QD, Thouless MD, Ward SM (2000) Analysis of the symmetrical 90°-peel test with extensive plastic deformation. J Adhes 72: 115–132

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Martiny, P., Lani, F., Kinloch, A.J. et al. A multiscale parametric study of mode I fracture in metal-to-metal low-toughness adhesive joints. Int J Fract 173, 105–133 (2012). https://doi.org/10.1007/s10704-011-9667-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-011-9667-x