Abstract

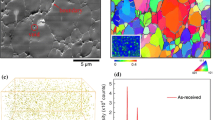

Investigation of the dynamic properties of aluminum targets with helium bubbles is presented. The targets were obtained by melting pure aluminum with 0.15% wt.10B powder. The solid targets were neutron irradiated to get homogeneous helium atoms inside the aluminum boron 10 matrix according to the reaction 10B + n → 7Li+4He. Helium atoms further accumulated into bubbles by diffusion in the bulk aluminum. Shock wave experiments were performed by accelerating the aluminum impactor into different targets: (1) pure aluminum, (2) Al-10B, and (3)Al-10B with different radii and concentrations of helium bubbles. The spall strength was calculated and analyzed from the free surface velocity measurements. It was found that the addition of 10B in pure aluminum reduces the spall strength of the material by 25–32%. However, irradiated sample with helium bubbles was found to have higher spall strength compared to samples without bubbles. This finding was reconstructed by numerical simulations. The impacted targets were collected after the impact experiments and examined by TEM. These targets were compared to TEM pictures before the impact. The number of helium atoms in the bubbles was calculated from the electron energy loss spectrum (EELS). TEM comparison between the pre-impacted and the impacted targets shows bubbles coalescence and EELS measurements demonstrate a reduction of the helium atoms concentration in the bubbles from ~1028 m−3 before the impact to ~1027 m−3 after the impact.

Similar content being viewed by others

References

Chen X, Asay JR, Dwivedi SK, Field DP (2006) Spall behavior of aluminum with varying microstructures. J Appl Phys 99: 023528

Chhabildas LC, Asay JR (1979) Rise-time measurements of shock transitions in aluminum, copper, and steel. J Appl Phys 50: 2749–2756

Eliezer S, Gilath I, Bar-Noy T (1990) Laser-induced spall in metals: experiment and simulation. J Appl Phys 67: 715–724

Foeman AJE, Singh BN (1985) Bubble nucleation in grain interior and its influence on helium accumulation at grain boundaries. J Nucl Mat 133: 451–454

Fortov VE, Kostin VV, Eliezer S (1991) Spallation of metals under laser irradiation. J Appl Phys 70: 4524–4531

Glam B, Moreno D, Eliezer S, Eliezer D (2009a) Experimental investigation of the helium migration in an fcc aluminum matrix. J Nuc Mat 393: 230–234

Glam B, Eliezer S, Moreno D, Eliezer D (2009b) Helium bubbles formation in aluminum: bulk diffusion and near-surface diffusion using TEM observations. J Nuc Mat 392: 413–419

Glyde HR, Mayne KL (1965) Helium diffusion in aluminum. J Nucl Mat 15: 997–1002

Grady DE (1988) The spall strength of condensed matter. J Mech Phys Solids 36(3): 353–384

Hansen PM (1958) Constitution of binary alloys. 2nd edn. McGraw-Hill, New York

Johnson JN (1981) Dynamic fracture and spallation in ductile solids. J Appl Phys 52(4): 2812–2824

Kubota A, Reisman DB, Wolfer WG (2006) Dynamic strength of metals in shock deformation. Appl Phys Lett 88: 241924

Marian J, Wirth BD, Perlado M (2002) Mechanism of formation and growth of 〈100〉 interstitial loops in ferritic materials. Phys Rev Lett 88: 255507

Moreno D, Eliezer D (1996) Stractural changes in a copper alloy due to helium implantation. Scrip Mat 35(12): 1385–1389

Pati SR, Barrad P (1969) The influence of precipitates on the formation of helium bubbles in irradiated copper-boron alloys. J Nucl Mat 31: 117–120

Preieto FE, Renero C (1973) Steady shock profile in solids. J Appl Phys 44: 4013–4016

Raicher E, Glam B, Henis Z, Pecker Z, Eliezer S, Moreno D (2009) Equation of State for aluminum containing helium bubbles. J Appl Phys 106: 083519

Razorenov SV, Kanel GI, Herrmann B, Zaretsky EB, Ivanchihina GE (2007) Influence of nano-size inclusions on spall fracture of copper single crystals. Shock compression of condensed matter—2007. APS Conf Proc 955: 581–584

Satou M, Koide H, Hasegawa A, Abe K, Kayano H, Matsui H (1996) Tensile behavior of helium charged V—Ti—Cr—Si type alloys. J Nucl Mat 234: 447–451

Trinkaus H, Singh BN (2003) Helium accumulation in metals during irradiation-where do we stand?. J Nucl Mat 323: 229–242

Trivedi PE, Asay JR, Gupta YM, Field DP (2007) Influence of grain size on the tensile response of aluminum under plate-impact loading. J Appl Phys 102: 083513

Wang Y, He H, Qi M, Shen L, Bai B (2007) Time-resolved dynamic compaction and tensile fracture of low-porosity aluminum under impact loading. J Appl Phys 102: 073518

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Glam, B., Eliezer, S., Moreno, D. et al. Dynamic fracture and spall in aluminum with helium bubbles. Int J Fract 163, 217–224 (2010). https://doi.org/10.1007/s10704-009-9437-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-009-9437-1