Abstract

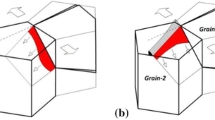

In ferritic steels a propagating cleavage microcrack changes its propagation direction as it advances from grain to grain. This is due to differences in the orientation of the cleavage planes of two neighboring grains. In order to reach a cleavage plane in a new grain, a microcrack must first penetrate the grain boundary. Grain boundaries therefore act as natural barriers in cleavage fracture. The influence of a grain boundary and the associated misorientation in cleavage planes on crack arrest is here examined using a 3D finite element model with axisymmetric periodicity, representing two grains whose cleavage planes are tilted and twisted relative to each other. The temperature dependent mechanical properties of ferrite are modeled using a temperature dependent viscoplastic response. The development of the crack front as the microcrack penetrates through a grain boundary is here presented. The influence of the twist misorientation on the critical grain size, defined as the largest grain size that can arrest a rapidly propagating microcrack, is examined in a temperature range corresponding to the ductile to brittle transition (DBT) region. It is shown that when both tilt and twist misorientation are present, the influence of tilt and twist, respectively, on crack growth resistance can be decoupled.

Similar content being viewed by others

References

ABAQUS (2006) Standard-user's manual, version 6.6. Hibbit, Karlsson and Sorensen Inc., Providence, RI

Anderson T, Stienstra D, Dodds RH Jr (1994) A theoretical framework for addressing fracture in the ductile-brittle transition region. In: Landes JD, McCabe DE, Boulet JAM (eds) Fracture mechanics 24:th volume ASTM STP 1207. American Society for Testing of Materials, Philadelphia, pp 186–214

Campbell JD, Ferguson WG (1970) The temperature and strain-rate dependence of the shear strength of mild steel. Philos Mag Lett 21: 63–82

Clatterbuck DM, Chrzan DC, Morris JW Jr (2003) The ideal strength of iron in tension and shear. Acta Materialia 51: 2271–2283

Crocker A, Smith G, Flewitt P, Moskovic R (1996) Grain boundary fracture in the cleavage regime of polycrystalline metals. In: Proceedings of the 11th European conference on fracture (EFC 11) Eng Mater Advis Serv, Warley, vol 1, pp 233–238

Faleskog J, Kroon M, Öberg H (2004) A probabilistic model for cleavage fracture with a length scale—parameter estimation and predictions of stationary crack experiments. Eng Fract Mech 71: 57–79

Faleskog J, Stec M (2009) Micromechanics and probabilistic modeling of cleavage microcrack nucleation and growth caused by particle cracking. Report 466, KTH Engineering Sciences, Solid Mechanics, Royal Institute of Technology. Submitted for publication

Flewitt PEJ, Wild RK (2001) Grain boundaries. Their microstructure and chemistry. John Wiley & Sons, Ltd, Chichester

François D, Pineau A, Zaoui A (1998) Mechanical behavior of materials. Volume II: viscoplasticity, damage, fracture and contact mechanics. Kluwer Academic Publisher, Dordrecht

Gell M, Smith E (1967) The propagation of cracks through grain boundaries in polycrystalline 3% silicon-iron. Acta Metallurgica 15: 253–258

Hamphreys FJ, Hatherly M (2004) Recrystallization and related annealing phenomena. 2nd edn. Elsevier Ltd, Oxford

Hahn GT (1984) The influence of microstructure on brittle fracture toughness. Metallurg Trans 15A: 947–959

Klopp RW, Clifton RJ, Shawki TG (1985) Pressure-shear impact and the dynamic viscoplastic response of metals. Mech Mater 4: 375–385

Kong X, Qiao Y (2005) Crack trapping effect of persistent grain boundary islands. Fatigue Fract Eng Mater Struct 28: 753–758

Kroon M, Faleskog J (2005) Micromechanics of cleavage fracture initiation in ferritic steels by carbide cracking. J Mech Phys Solids 53: 171–196

Kroon M, Faleskog J (2008) Influence of crack deflection into the carbide/ferrite interface on cleavage fracture initiation in ferritic steels. Mech Mater 40: 695–707

Lee S, Kim S, Hwang B, Lee BS, Lee CG (2002) Effect of carbide distribution on the fracture toughness in the transition temperature region of an SA 508 steel. Acta Materialia 50: 4755–4762

Linaza MA, Rodriguez Ibabe, Urcola JJ (1997) Determination of the energetic parameters controlling cleavage fracture initiation in steels. Fatigue Fract Eng Mater Struct 20: 619–632

Martín-Meizoso A, Ocaña-Arizcorreta I, Gil-Sevillano J, Fuentes-Pérez M (1994) Modelling of cleavage fracture of bainitic steels. Acta Metallurgica et Materialia 42: 2057–2068

McMahon CJ, Cohen M (1965) Initiation of cleavage in polycrystalline iron. Acta Metallurgica 13: 591–604

Ortiz M, Pandolfi A (1999) Finite-deformation irreversible cohesive elements for three-dimensional crack-propagation analysis. Int J Numer Methods Eng 44: 1267–1282

Qiao Y, Argon AS (2003a) Cleavage crack-growth-resistance of grain boundaries in polycrystalline Fe-2%Si alloy: experiments and modeling. Mech Mater 35: 129–154

Qiao Y, Argon AS (2003b) Cleavage cracking resistance of high angle grain boundaries in Fe-3% Si alloy. Mech Mater 35: 313–331

Qiao Y, Kong X (2004) An energy analysis of the grain boundary behavior in cleavage cracking in Fe-3wt.%Si alloy. Mater Lett 58: 3156–3160

Roychowdhury S, Roy YDA, Dodds RH Jr (2002) Ductile tearing in thin aluminum panels: experiments and analysis using large-displacement, 3-D surface cohesive elements. Eng Fract Mech 69: 983–1002

Smith G, Crocker A, Flewitt P (2004) Brittle fracture of polycrystals: development of a new three-dimensional model. In: Proceedings of the 15th European conference on fracture (ECF15), CD-ROM, KTH, Stockholm

Stec M, Faleskog J (2009) Influence of grain size on arrest of a dynamically propagating cleavage crack in ferritic steels—micromechanics. Int J Fract 158: 51–71

Tanguy B, Piques R, Laiarinandrasana L, Pineau A (1994) Mechanical behavior of a A508 steel based on a double nonlinear viscoplastic constitutive equation. In: Miannay D, Costa P, Francois D, Pineau A (eds) Euromat 2000, advances in mechanical behavior, plasticity and damage. Elsevier, Amsterdam, pp 499–504

Wallin K (1991) Fracture toughness transition curve shape for ferritic structural steels. In: Teoh ST, Lee KH (eds) Fracture of engineering materials and structures. Elsevier Applied Science, Oxford pp 83–88

Wallin K, Laukkanen A (2006) Aspects of cleavage fracture initiation —relative influence of stress and strain. Fatigue & Fracture of Engineering Materials and Structures 29: 788–798

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Stec, M., Faleskog, J. Micromechanical modeling of grain boundary resistance to cleavage crack propagation in ferritic steels. Int J Fract 160, 151–167 (2009). https://doi.org/10.1007/s10704-009-9415-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-009-9415-7