Abstract

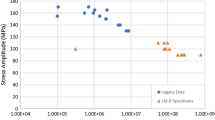

This paper discusses the relationship between striation spacing, i.e., the microscopic crack propagation rate, as measured in postmortem fractographic inspection of fatigue fractured surfaces, and the macroscopic crack propagation rate, i.e., da/dN, as monitored during fatigue crack growth tests. Compact tensile specimens C(T) in prevalent plane-strain conditions were extracted in LT orientation from the center of a 2-in. thick rolled plate of a SAE-AMS 7475-T7351 Al alloy. Testpieces were fatigue tested according to ASTM-E647 standard, at room temperature in a servo-hydraulic closed-loop MTS testing machine operating with the unloading elastic compliance technique. da/dN-ΔK data points were collected in the Paris’ law validity region, with crack growth rates typically ranging from 0.18 to 2.02 µm/cycle. Topographical survey was conducted on the test specimen fracture surfaces in a scanning electronic microscope in order to determine striation spacing created during the fatigue test. Macro- and micro-crack growth rates were compared and good correlation have been obtained for the data within the range of ΔK assessed in the study. Results of crack growth rates have been quantitatively evaluated in terms of fatigue life estimation.

Similar content being viewed by others

References

ASM Handbook (1996) Fatigue and Fracture, vol. 19. ASM International, Materials Park, OH

ASTM E-8M (2000) Standard test method for tension testing of metallic materials [metric], Annual Book of ASTM Standards. pp. 1–22. 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States

ASTM E-647 (2005) Standard test method for measurement of fatigue crack growth rates, Annual Book of ASTM Standards. pp. 1–45. 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States

Broek D (1969) The effect of intermetallic particles on crack propagation in aluminium alloys. In: Proceedings of the 2nd International Conference on Fracture, Fracture 1969, Chapman and Hall, pp. 754–764

Davidson DL, Lankeford J (1992) Fatigue crack growth in metals and alloys: mechanisms and micromechanics. Int Mater Rev 37:45–76

Miller GA (1968) The dependence of fatigue-crack growth rate on the stress intensity factor and the mechanical properties of some high-strength steels. Trans ASM. 61, 442–448

Murakami Y, Shiraishi N, Furukawa K (1990) Estimation of service loading from the width an height of fatigue striations of 2017-T4 Al Alloy. Fatigue and fracture of engineering materials and structures. vol. 14, no. 9, pp. 897–906. 1991

Nedbal I, Siegl J, Kunz J (1994) Relation between striation spacing and fatigue crack growth rate in Al-Alloy Sheets. In: Salama K et al., (eds) Advances in fracture research (Proc. ICF 7, Houston), vol 5. Pergamon Press, Oxford, pp. 3483–3491

Paris PC, Erdogan F (1963) Trans. ASME. J Basic Eng 85:528

Society of Automotive Engineers - SAE-AMS 4202C (1989) Aerospace material specification for 7475-T7351 aluminum alloy, American National Standard. The engineering society for advancing mobility land and sea air and space. pp. 1–9

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ruckert, C.O.F.T., Tarpani, J.R., Filho, W.W.B. et al. On the relation between micro- and macroscopic fatigue crack growth rates in aluminum alloy AMS 7475-T7351. Int J Fract 142, 233–240 (2006). https://doi.org/10.1007/s10704-006-9029-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-006-9029-2