Abstract

A mixed-model assembly line requires the solution of a short-term sequencing problem, which decides on the succession of different models launched down the line. A famous solution approach stemming from the Toyota Production System is the so-called Level Scheduling (LS), which aims to distribute the part consumption induced by a model sequence evenly over the planning horizon. LS attracted a multitude of different researchers, who, however, invariably treat initial sequence planning where all degrees of freedom in assigning models to production cycles exist. In the real-world, conflicting objectives and restrictions of preceding production stages, i.e., body and paint shop, simultaneously need to be considered and perturbations of an initial sequence will regularly occur, so that the sequencing problem often becomes a resequencing problem. Here, a given model sequence is to be reshuffled with the help of resequencing buffers (denoted as pull-off tables). This paper shows how to adapt famous solution approaches for alternative LS problems, namely the Product-Rate-Variation (PRV) and the Output-Rate-Variation (ORV) problem, if the (re-)assignment of models to cycles is restricted by the given number of pull-off tables. Furthermore, the effect of increasing re-sequencing flexibility is investigated, so that the practitioner receives decision support for buffer dimensioning, and the ability of the PRV in reasonably approximating the more detailed ORV in a resequencing environment is tested.

Similar content being viewed by others

References

Bautista J, Companys R, Corominas A (1996) Heuristics and exact algorithms for solving the Monden problem. Eur J Operat Res 88:101–113

Boysen N, Fliedner M, Scholl A (2009a) Sequencing mixed-model assembly lines: survey, classification and model critique. Eur J Operat Res 192:349–373

Boysen N, Fliedner M, Scholl A (2009b) The product rate variation problem and its relevance in real world mixed-model assembly lines. Eur J Operat Res 197:818–824

Brauner N, Crama Y (2004) The maximum deviation just-in-time scheduling problem. Discrete Appl Math 134:25–50

Dhamala TN, Kubiak W (2005) A brief survey of just-in-time sequencing for mixed-model systems. International Journal of Operations Research 2: 38–47

Ding F-Y, Cheng L (1993a) A simple sequencing algorithm for mixed-model assembly lines in just-in-time production systems. Operat Res Lett 13:27–36

Ding F-Y, Cheng L (1993b) An effective mixed-model assembly line sequencing heuristic for just-in-time production systems. J Operat Manag 11:45–65

Ding F-Y, Sun H (2004) Sequence alteration and restoration related to sequenced parts delivery on an automobile mixed-model assembly line with multiple departments. Int J Product Res 42:1525–1543

Fliedner M, Boysen N, Scholl A (2010) Solving symmetric mixed-model multi-level just-in-time scheduling problems. Discrete Appl Math 158:222–231

Gusikhin O, Caprihan R, Stecke KE (2008) Least in-sequence probability heuristic for mixed-volume production lines. Int J Product Res 46:647–673

Hopcroft J, Karp R (1973) An n2.5 algorithm for maximum matching in bipartite graphs. SIAM J Comput 2:225–231

Inman RR, Bulfin RL (1991) Sequencing JIT mixed-model assembly lines. Manag Sci 37:901–904

Inman RR, Bulfin RL (1992) Quick and dirty sequencing for mixed-model multi-level JIT systems. Int J Product Res 30:2011–2018

Inman RR, Schmeling DM (2003) Algorithm for agile assembly-to-order in the automotive industry. Int J Product Res 41:3831–3848

Kubiak W (1993) Minimizing variation of production rates in just-in-time systems: a survey. Eur J Operat Res 66:259–271

Kubiak W (2003) Cyclic just-in-time sequences are optimal. J Global Optim 27:333–347

Kubiak W, Sethi SP (1991) A note on “level schedules for mixed-model assembly lines in just-in-time production systems”. Manag Sci 37:121–122

Kubiak W, Sethi SP (1994) Optimal just-in-time schedules for flexible transfer lines. Int J Flexible Manuf Syst 6:137–154

Kubiak W, Steiner G, Yeomans JS (1997) Optimal level schedules for mixed-model, multi-level just-in-time assenbly systems. Ann Operat Res 69:241–259

Lahmar M, Benjaafar S (2007) Sequencing with limited flexibility. IIE Trans 39:937–955

Lahmar M, Ergan H, Benjaafar S (2003) Resequencing and feature assignment on an automated assembly line. IEEE Trans Robotics 19:89–102

Lim A, Xu Z (2009) Searching optimal resequencing and feature assignment on an automated assembly line. J Operat Res Soc 60:361–371

Lowerre BT (1976) The HARPY speech recognition system. Ph.D. thesis, Carnegie-Mellon University, USA, April

Miltenburg J (1989) Level Schedules for mixed-model assembly lines in just-in-time production systems. Manag Sci 35:192–207

Monden Y (1998) Toyota production system: an integrated approach to just-in-time. 3rd edn, Norcross

Ow PS, Morton TE (1988) Filtered beam search in scheduling. Int J Product Res 26:297–307

Sabuncuoglu I, Gocgun Y, Erel E (2008) Backtracking and exchange of information: methods to enhance a beam search algorithm for assembly line scheduling. Eur J Operat Res 186:915–930

Spieckermann S, Gutenschwager K, Voss S (2004) A sequential ordering problem in automotive paint shops. Int J Product Res 42:1865–1878

Steiner G, Yeomans JS (1993) Level schedules for mixed-model, just-in-time processes. Manag Sci 39:728–735

Author information

Authors and Affiliations

Corresponding author

Appendix proof of feasibility condition

Appendix proof of feasibility condition

Proposition

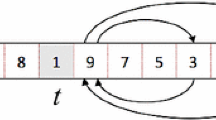

A sequence π = < 1,…,T > can be resequenced to a new sequence represented by mapping \(\sigma:\{1,\ldots,T\}\rightarrow \{1,\ldots,T\}\) by use of K pull-off tables if and only if\(\sigma(i) {\geq} i - K \quad \forall i=1,\ldots,T\).

Proof

Necessity of the condition follows directly from the fact that if σ(i) < i − K for any model i then i − σ(i) > K, which means that more than K models would need to be stored simultaneously in order for model i to arrive at its position in σ.

In order to prove sufficiency, we will use a recursive argument to show that a feasible mapping for any sequence π can be readily constructed on the basis of a shorter sequence for which a feasible mapping is known. Specifically, we show that σ is a feasible mapping of π if \(1 {\geq}\sigma^{-1}(1)-K\), with σ−1(1) denoting the model assigned to the first position of the new sequence, and it further holds that \(\sigma'\{1,\ldots,\sigma^{-1}(1)-1,\sigma^{-1}(1)+1,\ldots,T\}\rightarrow\{1,\ldots,T-1\}\) constitutes a feasible mapping of the reduced sequence \(\pi'=<1,\ldots,\sigma^{-1}(1)-1,\sigma^{-1}(1)+1,\ldots,T>\) with \(\sigma'(i)=\sigma(i)-1 {\quad}{\forall}i=1,{\ldots,T}{\land}i\,{\neq}\,\sigma^{-1}(1)\).

Suppose that σ′ is a feasible mapping for π′ then it follows from \(K+1 {\geq}\sigma^{-1}(1)\) that the first σ−1(1) − 1 models of sequence π′ can be stored in K pull-off tables. Since models from pull-off tables can be accessed in arbitrary order, there in fact has to exist a feasible resequencing strategy which stores the first σ−1(1) − 1 models of π′ in pull-off tables and then inserts them in accordance with their sequence position in σ′.

With regard to π, assigning model σ−1(1) to the first position in the new sequence cannot cause infeasibility as long as \(1 {\geq}\sigma^{-1}(1)-K\) holds. A feasible mapping of π thus exists, if there is a resequencing strategy which assigns the remaining models to the T − 1 remaining sequencing positions under the condition that the first σ−1(1) − 1 models of π have to be pulled off-line. Since the first σ−1(1) − 1 models of π and π′(i) are identical, it follows that we can readily construct a feasible mapping for π from σ′ by a simple relabeling of sequence positions for all remaining models with \(\sigma(i)=\sigma'(i)+1 \quad \forall i=1,\ldots,T \land i\,{\neq}\,\sigma^{-1}(1)\). The feasibility of σ′ is thus sufficient for the feasibility of σ if \(1 {\geq}\sigma^{-1}(1)-K\).

The same argument can now be applied to π′ and σ'-1(1) and then repeatedly to any reduced sequence of positive length which after relabeling yields the required conditions \(\sigma(i) {\geq} i - K \quad \forall i=1,\ldots,T\). \(\square\)

Rights and permissions

About this article

Cite this article

Boysen, N., Fliedner, M. & Scholl, A. Level scheduling under limited resequencing flexibility. Flex Serv Manuf J 22, 236–257 (2010). https://doi.org/10.1007/s10696-010-9065-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10696-010-9065-0