Abstract

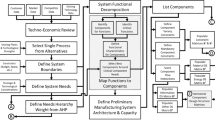

The standard approach for design of a layout for a high-variety low-volume (HVLV) manufacturing facility has been to use either a from-to chart or a multi-product process chart to design a process layout or a cellular layout, respectively, for the facility. Considerable research has focused on making a go-no go decision to implement any one of these two traditional layouts as the preferred layout for an HVLV manufacturing facility. This paper introduces a variety of Hybrid Cellular Layouts (HCLs) which integrate the attributes of the traditional functional, cellular and flowline layouts. The mathematical models and methods for design of two HCLs—cascading flowline layout and modular layout—are discussed in detail. Unlike the standard models in the literature, the design of the cascading flowline layout introduces a novel string-to-graph aggregation and planar graph embedding method that allows machine duplication in the layout. Similarly, the design of the Modular layout introduces a substring clustering method instead of the standard method of cluster analysis to form part families using the complete routings of the parts. For each HCL, results from an industry project are presented to demonstrate the real-world viability of the concepts, methods and software developed to support the design of HCLs for high-variety low-volume manufacturing facilities.

Similar content being viewed by others

References

Arvindh B, Irani SA (1994) Cell formation: The need for integrated solution of the subproblems. International Journal of Production Research 32(5):1197–1218

Askin RG, Lundgren NH, Ciarallo F (1996) A material flow based evaluation of layout alternatives for agile manufacturing. In (Graves RJ et. al.), Progress in material handling research, Ann Arbor, MI: Material Handling Institute, Braun-Brumfield Inc., 71–90

Askin RG, Zhou M (1998) Formation of independent flowline cells based on operation requirements and machine capabilities. IIE Transactions 30:319–329

Benjaafar S, Sheikhzadeh M (2000) Design of flexible plant layouts. IIE Transactions 32:309–322

Drolet JR, Moodie CL, Montreuil B (1989) An expansion of the virtual cell concept for scheduling computer integrated manufacturing systems. In Proceedings of the IFAC International Workshop on Decisional Structures in Automated Manufacturing, pp. 9–24

Foulds LR, Giffin JW (1985) A graph theoretic heuristic for minimizing total transport cost in facilities layout. International Journal of Production Research 23(6):1247–1257

Gusfield D (1997) Algorithms on strings, trees and sequences: Computer science and computational biology, Cambridge University Press, London, UK

Huang H, Irani SA (2003) An enhanced systematic layout planning (SLP) process for high-variety low-volume (HVLV) manufacturing facilities. In Proceedings of the Seventeenth International Conference on Production Research, Virginia Polytechnic Institute and State University, Blacksburg, VA [CD-ROM]

Irani SA, Huang H (2000) Custom design of facility layouts for multi-product facilities using layout modules. IEEE Transactions on Robotics and Automation (Special Issue on Manufacturing Systems Design) 16(3):259–267

Irani SA, Zhang H, Zhou J, Huang H, Tennati KU, Subramanian S (2000) Production flow analysis and simplification toolkit (PFAST). International Journal of Production Research 38(8):1855–1874

Irani SA, Cohen PH, Cavalier TM (1992) Design of cellular manufacturing systems. Journal of Engineering for Industry 114(3):352–361

Irani SA, Cavalier T M, Cohen PH (1993) Virtual manufacturing cells: Exploiting layout design and intercell flows for the machine sharing problem. International Journal of Production Research 31(4):791–810

Irani SA, Huang H (2000) Custom design of facility layouts for multi-product facilities using Layout Modules. IEEE Transactions on Robotics and Automation 16(3):259–267

Jensen JB, Malhotra MK, Philipoom PR (1996) Machine dedication and process flexibility in a group technology environment. Journal of Operations Management 14:19–39

Kochhar JS, Heragu SS (1999) Facility layout design in a changing environment. International Journal of Production Research 37(11):2429–2446

McCormick WT, Schweitzer PJ, White TW (1972) Problem decomposition and data reorganization by a clustering technique. Operations Research 20(5):993–1009

Meller RD (2000) Multi-channel manufacturing. White Paper, Department of Industrial and Systems Engineering, Auburn University, Auburn, AL

Montreuil B (2000) Design of agile factory networks for fast-growing companies. In The 6th International Colloquium on Material Handling Research, York, PA

Montreuil B, Lefrancois P (1996) Organizing factories as responsibility networks. Graves R.J. et al., In Progress in Material Handling Research Ann Arbor, MI: Material Handling Institute, Braun-Brumfield Inc., pp. 375–411

Mulvey JM, Crowder H (1979) Cluster analysis: An application of Lagrangian relaxation. Management Science 25(4):329–340

Parker RG, Rardin RL (1982) An overview of complexity theory in discrete optimizations (Part I): Concepts. IIE Transactions 14(1):3–10

Sankoff D, Kruskal JB (1983) Time Warps, String Edits and Macromolecules: The Theory and Practice of Sequence Comparison, Reading, Addison-Wesley, MA

Sherali HD, Fraticelli BMP, Meller RD (2003) Enhanced model formulations for optimal facility layout. Operations Research 51(4):629–644

Suresh NC, Slomp J (2005) Performance comparison of virtual cellular manufacturing with functional and cellular layouts in DRC settings. International Journal of Production Research 43(5):945–979

Tarjan RE (1973) Depth-first search and linear graph algorithms. SIAM Journal on Computing 1:146–160

Tompkins JA, White JA, Bozer YA, Tanchoco JMA (2003) Facilities Planning, NY: John Wiley, New York.

Vakharia AJ, Moily JP, Huang Y (1999) Evaluating virtual cells and multistage flow shops: an analytical approach. The International Journal of Flexible Manufacturing Systems 11:291–314

Vakharia AJ, Wemmerlov U (1990) Designing a cellular manufacturing system: A materials flow approach based on operation sequences. IIE Transactions 22(1):84–97

Venkatadri U, Rardin R, Montreuil B (1997) A design methodology for fractal layout organization. IIE Transactions 29:911–924

Zhou J, Irani SA (2003) A new flow diagramming scheme for mapping and analysis of multi-product flows in a facility. Journal of Integrated Design and Process Science 7(1):25–58

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Irani, S.A., Huang, H. Cascading flowlines and layout modules: Practical strategies for machine duplication in facility layouts. Int J Flex Manuf Syst 17, 119–149 (2005). https://doi.org/10.1007/s10696-006-8124-z

Issue Date:

DOI: https://doi.org/10.1007/s10696-006-8124-z