Abstract

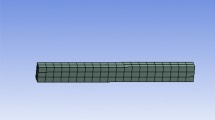

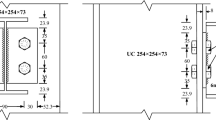

High-strength steel has been extensively used in numerous structures or high-rise buildings because of its high strength, ductility, and weldability. However, high-strength steel structures are vulnerable to fire hazards, so the ability to predict structural behavior is crucial in structural fire safety design. Creep behavior is one of the primary factors influencing the response of steel at high temperatures. This paper presents numerical studies using the fire dynamics simulator (FDS) and finite element method (FEM) coupling models to predict the structural behavior of a protected beam with a cavity for H-SA700 high-strength steel at elevated temperatures, including the creep effect. A comparison between simulation and experiment results demonstrates the validity of the process. In detail, based on a set of tensile tests conducted at six constant temperatures between 23°C and 600°C, the creep model is proposed. Subsequently, because creep is temperature-dependent, the heat transfer model used to predict the temperature distribution of the steel is developed. The effect of the partially damaged protection cover is discussed. Finally, it is found that with the temperature distribution from FDS-FEM integration and the proposed creep models, the collapse time of the beam can be defined. This study provides a practical approach for developing the creep model without creep tests and applying it to complex structures during fires.

Similar content being viewed by others

References

Fu L, Xu G, Yan Y, Yang J, Xie J (2018) The application and research progress of high strength and high performance steel in building structure. IOP Conf Ser Mater Sci Eng 392(2):022008. https://doi.org/10.1088/1757-899X/392/2/022008

Bjorhovde R (2004) Development and use of high performance steel. J Constr Steel Res 60(3–5):393–400. https://doi.org/10.1016/S0143-974X(03)00118-4

Phan QT, Kohno M, Murakami Y, Nguyen HL (2022) Modeling of creep behavior of high strength steel H-SA700 columns at elevated temperature. Fire Sci Technol 41(1):1–20. https://doi.org/10.3210/fst.41.1

Wang WY, Liu B, Kodur VKR (2013) Effect of temperature on strength and elastic modulus of high-strength steel. J Mater Civil Eng 25(2):174–182. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000600

Kodur VK, Aziz EM (2015) Effect of temperature on creep in ASTM A572 high-strength low-alloy steels. Mater Struct 48(6):1669–1677. https://doi.org/10.1617/s11527-014-0262-2

Wang W, Zhang L, He P (2019) A numerical investigation on restrained high strength Q460 steel beams including creep effect. Int J Steel Struct 18:1497–1507. https://doi.org/10.1007/s13296-018-0047-5

Al-azzani H, Yang J, Sharhan A, Wang W (2021) A practical approach for fire resistance design of restrained high-strength Q690 steel beam considering creep effect. Fire Technol 57:1683–1706. https://doi.org/10.1007/s10694-020-01078-7

Wang W, Yan S, Liu J (2017) Studies on temperature induced creep in high strength Q460 steel. Mater Struct 50(1):68. https://doi.org/10.1617/s11527-016-0941-2

EN 1993-1-2 (2005) Eurocode 3: design of steel structures—part 1–2: general rules—structural fire design. British Standard Institution, London

ECCS Technical Committee 3 (1983) European recommendations for the fire safety of steel structures. Elsevier Scientific Publishing Company, Amsterdam

China Association for Engineering Construction Standardization (CECS200) (2006) Technical code for fire safety of steel structure in buildings. China Planning Press, Beijing (in Chinese)

Silva VP, Fakury RH (2002) Brazilian standard for steel structures fire design. Fire Saf J 37(2):217–227

Nguyen HL, Kohno M (2023) Numerical model of heat transfer for protected steel beam with cavity under ISO 834 standard fire. Fire Saf J 140:103876. https://doi.org/10.1016/j.firesaf.2023.103876

Norton FH (1929) The creep of steel at high temperatures. McGraw-Hill Inc., New York

Bailey RW (1930) Creep of steel under simple and compound stress. Engineering 121:265

National Institute of Standards and Technology, Federal building and Fire safety investigation of the World Trade Center Disaster (2005) Mechanical properties of structural steels, Report NIST NCSTAR 1-3D

Fields BA, Fields RJ (1989) Elevated Temperature Deformation of Structural Steel. National Institute of Standards and Technology, NIST

The Iron and Steel Federation of Japan (2012) High strength 780 N/mm2 steel for building construction (H-SA700), Product Specifications MDCR 0015-2012 (in Japanese)

Method of elevated temperature tensile test for steels and heat-resisting alloys, Japan Industrial Standards, Japanese Standards Association

Li GQ, Wang XX, Zhang C, Cai WY (2020) Creep behavior and model of high-strength steels over 500 MPa at elevated temperatures. J Constr Steel Res 168:105989. https://doi.org/10.1016/j.jcsr.2020.105989

Horii R, Suzuki J, Wang Y, Ohmiya Y (2020) Numerical simulation of steel elements with partially damaged fire protection in standard fire. Proceedings of annual meeting, Japan Society of Finishing Technology. pp 177–180 (in Japanese)

Suzuki J, Mizukami T, Hayashi Y, Naruse T, Tominaya R, Wang Y, Ohmiya Y (2017) Temperature Rise Characteristics of Steels elements with partially damaged fire protection in standard fire. Proceedings of JAFSE Annual Symposium: 296–297 (in Japanese)

Lee CH, Chiou YJ, Chung HY, Chen CJ (2011) Numerical modeling of the fire–structure behavior of steel beam-to-column connections. J Constr Steel Res 67(9):1386–1400. https://doi.org/10.1016/j.jcsr.2011.02.014

Li GQ, Chao Z (2017) Integrated fire-structure simulation of localized fire test on a ceiling steel beam. Adv Steel Constr 13(2):132–143. https://doi.org/10.18057/IJASC.2017.13.2.3

Kentec Corporation, Properties of ISOWOOL blanket http://www.ken-tec.co.jp/isowool/ (in Japanese)

Architectural Institute of Japan (2017) Guidebook for fire-resistive performance of structural materials

ALC Association (2013) ALC Panel Structural Design Guidelines and Commentary (in Japanese)

Choi IR, Chung KS, Kim DH (2014) Thermal and mechanical properties of high-strength structural steel HSA800 at elevated temperatures. Mater Des 63:544–551. https://doi.org/10.1016/j.matdes.2014.06.035

Chen J, Young B, Uy B (2006) Behavior of high strength structural steel at elevated temperatures. J Struct Eng 132:1948–1954. https://doi.org/10.1061/(ASCE)0733-9445(2006)132:12(1948)

Abaqus/CAE User's Manual (2014) Dassault systèmes simulation corporation

Tomecek DV, Milke JA (1993) A study of the effect of partial loss of protection on the fire resistance of steel columns. Fire Technol 29:3–21. https://doi.org/10.1007/BF01215355

Milke JA, Ryder NL (2003) Analyses of the impact of loss of spray-applied fire protection on the fire resistance of steel columns. Fire Saf Sci 7:1025–1036. https://doi.org/10.3801/IAFSS.FSS.7-1025

Acknowledgements

We would like to convey our sincere gratitude to the Japan Iron and Steel Federation (Mr. Tachu Terasawa of Nippon Steel Corporation and Mr. Yukio Murakami of JFE Steel Corporation) for providing the test data and to Dr. Jun-ichi Suzuki and Prof. Wang Yu-hsiang for their insightful comments and data. The contributions of Hoai Duc Trinh and Quoc Tuan Phan to this study are also gratefully appreciated.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nguyen, H.L., Kohno, M. A Numerical Investigation of High-Strength Steel H-SA700 of Protected Beam with Cavity Under Elevated Temperature Including Creep Behavior. Fire Technol (2024). https://doi.org/10.1007/s10694-024-01576-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10694-024-01576-y