Abstract

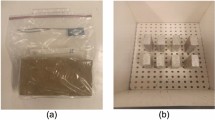

Tolerance gaps in wood connections are unavoidable, for reasons of constructability and the effects of natural shrinkage in timber elements with changing moisture content. During a fire, these gaps may lead to a substantial heat transfer to the metal connectors that are considered heat protected being embedded by the wooden components of the connection. Aluminium connectors are popular due to their ease of production and assembly, but they are particularly vulnerable to elevated temperatures. This study investigates the effects of tolerance gaps on the fire performance of aluminium connectors in beam-to-column/wall shear connections. Reduced-scale experiments were designed to study the temperature evolution of aluminium connectors during standard fire exposure for 1 mm and 6 mm tolerance gaps, as well the mitigation effects of additional intumescent fire protection in a 6 mm tolerance gap connection. For the 6 mm gap, the temperature of the connector increased much faster, reaching 286 ± 36°C after 80 min, at which time the connector with a 1 mm gap had only reached 97 ± 1°C. The addition of intumescent protection in a 6 mm gap case led to lower temperatures in the connection, in comparison to an equivalent tolerance gap without protection. Subsequently, two additional loaded fire tests were performed, for 6 mm and 22 mm tolerance gaps without fire protection, to investigate the critical failure mode of the connectors. In these cases, the failure occurred in the connectors at 87 min and 32 min, respectively, when their average temperatures reached approximately 315°C. This study demonstrates the critical influence of gap size on the fire performance of aluminium-wood joints.

Similar content being viewed by others

References

Smith RE, Griffin G, Rice T, Hagehofer-Daniell B (2018) Mass timber: evaluating construction performance. Archit Eng Des Manag 14:127–138. https://doi.org/10.1080/17452007.2016.1273089

Churkina G, Organschi A, Reyer CPO et al (2020) Buildings as a global carbon sink. Nat Sustain 3:269–276. https://doi.org/10.1038/s41893-019-0462-4

Barber D (2017) Determination of fire resistance ratings for glulam connectors within US high rise timber buildings. Fire Saf J 91:579–585. https://doi.org/10.1016/j.firesaf.2017.04.028

Barber D, Gerard R (2015) Summary of the fire protection foundation report - fire safety challenges of tall wood buildings. Fire Sci Rev 4:5. https://doi.org/10.1186/s40038-015-0009-3

McKenzie WMC, Zhang B (2007) Design of structural timber: to eurocode 5. Palgrave Macmillan

Buchanan A, Östman B (2022) Fire safe use of wood in buildings: global design guide, 1st edn. CRC Press, Boca Raton

Rijsdijk JF, Laming PB (1994) Physical and related properties of 145 timbers: information for practice. Kluwer Academic Publishers, Dordrecht, Boston

Maraveas C, Miamis K, Matthaiou ChE (2015) Performance of timber connections exposed to fire: a review. Fire Technol 51:1401–1432. https://doi.org/10.1007/s10694-013-0369-y

Palma P, Frangi A, Hugi E, et al (2014) Fire resistance tests on beam-to-column shear connections. In: Proceedings of the 8th international conference on structures in fire (SiF 2014). ETH Zurich, Shanghai, China

Palma P, Frangi A, Hugi E et al (2016) Fire resistance tests on timber beam-to-column shear connections. J Struct Fire Eng 7:41–57. https://doi.org/10.1108/JSFE-03-2016-004

Du Plessis M, Sulon D, Streicher D, Walls R (2023) Experimental testing on timber connections considering the influence of gap size and intumescent sealants. Fire Mater. https://doi.org/10.1002/fam.3164

CEN (2007) EN 1999-1-2 Eurocode 9. Design of aluminium structures—part 1–2: structural fire design. European Committee for Standardisation, Brussels

CEN (2016) EN 755-2 aluminium and aluminium alloys—extruded rod/bar, tube and profiles—part 2: mechanical properties. European Committee for Standardisation, Brussels

Friðriksdóttir HM (2022) Fire resistance of aluminum wood joints with tolerance gaps. Master’s Thesis, Technical University of Denmark

Friðriksdóttir HM, Larsen F, Pope I, et al (2022) Fire behaviour of aluminium-wood joints with tolerance gaps. In: Proceedings of the 12th international conference on structures in fire (SiF 2022). The Hong Kong Polytechnic University, Hong Kong, pp 635–646

Lange D, Sjöström J, Schmid J et al (2020) A comparison of the conditions in a fire resistance furnace when testing combustible and non-combustible construction. Fire Technol 56:1621–1654. https://doi.org/10.1007/s10694-020-00946-6

Rothoblaas intumescent thermo-inflatable flexible gasket: fire stripe. Rothoblaas. https://www.rothoblaas.com/products/airtightness-and-waterproofing/tapes-and-sealants/tapes-and-profiles/fire-stripe. Accessed 18 Oct 2022

CEN (2018) EN 13501-1:2018 fire classification of construction products and building elements—part 1: classification using data from reaction to fire tests. European Committee for Standardisation, Brussels

ISO (1999) ISO 834–1:1999 fire-resistance tests—elements of building construction—part 1: general requirements. International Organization for Standardization, Geneva

Servomex SERVOPRO 4900 Multigas Product brochure. Servomex. In: Servomex. https://www.servomex.com/. Accessed 18 Oct 2022

Keysight 34970A Data acquisition/data logger switch unit. In: Keysight. https://www.keysight.com/us/en/product/34970A/34970a-data-acquisition-control-mainframe-modules.html. Accessed 18 Oct 2022

Pope I, Hidalgo JP, Hadden RM, Torero JL (2022) A simplified correction method for thermocouple disturbance errors in solids. Int J Therm Sci 172:107324. https://doi.org/10.1016/j.ijthermalsci.2021.107324

CEN (2004) EN 1995-1-2 Eurocode 5. Design of timber structures—Part 1–2: General—Structural fire design. European Committee for Standardisation, Brussels

Gernay T, Zehfuß J, Brunkhorst S et al (2022) Experimental investigation of structural failure during the cooling phase of a fire: Timber columns. Fire Mater fam. https://doi.org/10.1002/fam.3110

Wiesner F, Hadden R, Deeny S, Bisby L (2022) Structural fire engineering considerations for cross-laminated timber walls. Constr Build Mater 323:126605. https://doi.org/10.1016/j.conbuildmat.2022.126605

Horne P, Abu A, Palermo A, Moss P (2023) Thermal response of timber connections in the cooling phase. Fire Mater 47:479–497. https://doi.org/10.1002/fam.3136

Acknowledgements

The authors would like to thank Rothoblaas for supplying the connectors and fire-stripes, and Stora Enso, for supplying the wood materials. The authors are also grateful to Lennart Schou Jensen, Kim S. Bergquist, Niklas Overgaard, and Aline Uldry from DBI for their assistance with the tests.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no financial or non-financial competing interests related to the work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sauca, A., Pope, I., Friðriksdóttir, H.M. et al. The Influence of Tolerance Gaps on the Fire Performance of Aluminium-Wood Joints. Fire Technol (2023). https://doi.org/10.1007/s10694-023-01504-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10694-023-01504-6