Abstract

Façade fires in tall buildings are currently occurring more than once a month globally that are responsible for many casualties and billions of dollars in losses. In particular, the tragic Grenfell Tower fire in London with more than 70 fatalities raised the profile of façade fire hazard. This work used well-controlled irradiation up to 60 kW/m2 to re-assess the fire hazard of typical flame-retardant aluminum composite panels (ACPs) with a dimension of 10 cm × 10 cm × 0.5 cm. We found that the vertically oriented ACPs with the “non-combustible” A2-grade and “limited-combustible” B-grade cores could still be ignited above 35 kW/m2 and 25 kW/m2, after the front aluminum layer peeled off. The peak heat release rate per unit area of these ACPs could be higher than common materials like timber and PVC. Moreover, compared to the B-core panel, the A2-core panel showed a greater fire hazard in terms of a shorter ignition delay time, a higher possibility of the core peel-off, and a longer flaming duration under current test size and fixing condition. Because the ACP is a complex system, its fire hazard is not simply controlled by the core material. The structural failure of ACP in fire, including peel-off, bending, softening and cracking, may further increase the fire hazard depending on the scale effect, boundary and fixing conditions. This research improves our understanding of the systematic fire behaviors of façade panels and helps rethink the fire risk and test methods of the building façade.

Graphical Abstract

Similar content being viewed by others

Notes

Flammable generally means that the material can support a flaming fire.

The test standard does not explicitly define what are “non-combustible,” “limited combustible,” “flammable” etc., but these simple terminologies are widely interpreted and used in the market, sometimes in a wrong way.

References

Knaack U, Klein T, Bilow M, Auer T (2014) Façades: principles of construction. Birkhäuser, Basel

Srivastava G, Nakrani D, Ghoroi C (2020) Performance of combustible facade systems with glass ACP and firestops in Full-scale real fire experiments. Fire Technol. https://doi.org/10.1007/s10694-019-00943-4

Hajduković M, Knez N, Knez F, Kolšek J (2017) Fire performance of external thermal insulation composite system (ETICS) facades with expanded polystyrene (EPS) insulation and thin rendering. Fire Technol 53:173–209

Hidalgo JP, McLaggan MS, Osorio AF et al (2019) Protocols for the Material Library of Cladding Materials—Part I: Framework. School of Civil Engineering, The University of Queensland

McLaggan MS, Hidalgo JP, Osorio AF et al (2019) Protocols for the Material Library of Cladding Materials—Part II: Sample preparation and testing methodologies. School of Civil Engineering, The University of Queensland

Heitzmann M, McLaggan MS, Hidalgo JP et al (2019) Protocols for the Material Library of Cladding Materials—Part III: Sensitivity studies. School of Civil Engineering, The University of Queensland

Hidalgo JP, McLaggan MS, Osorio AF et al (2019) Protocols for the Material Library of Cladding Materials—Part IV: Use and interpretation. School of Civil Engineering, The University of Queensland

McLaggan MS, Hidalgo JP, Carrascal J et al (2020) Flammability trends for a comprehensive array of cladding materials. Fire Saf J. https://doi.org/10.1016/j.firesaf.2020.103133

Nishio Y, Yoshioka H, Noguchi T et al (2016) Fire spread caused by combustible facades in Japan. Fire Technol 52:1081–1106. https://doi.org/10.1007/s10694-015-0535-5

Bonner M, Rein G (2018) Flammability and multi-objective performance of building façades: Towards optimum design. Int J High-Rise Build 7:363–374. https://doi.org/10.21022/IJHRB.2018.7.4.363

Bo T, Chen Y, Chun A, et al (2019) Safety awareness of firefighters and their perception of fire risks in cladding fires. In: AFAC19 powered by INTERSCHUTZ—Bushfire and Natural Hazards CRC Research Forum. Australian Institute for Disaster Resilience, pp. 93–102

Sun X, Hu L, Yang Y et al (2020) Evolutions of gas temperature inside fire compartment and external facade flame height with a casement window. J Hazard Mater 381:120913. https://doi.org/10.1016/j.jhazmat.2019.120913

Schulz J, Kent D, Crimi T et al (2020) A Critical Appraisal of the UK’s regulatory regime for combustible façades. Fire Technol. https://doi.org/10.1007/s10694-020-00993-z

Torero JL (2018) Grenfell Tower: Phase 1 Report. Grenfell Tower Inquiry

Bisby L (2018) Phase 1—Final Expert Report. Grenfell Tower Inquiry

Purser D Grenfell Tower Public Inquiry. In: 2018. https://www.grenfelltowerinquiry.org.uk/hearings/expert-evidence-professor-purser. Accessed 29 Nov 2018

McKenna ST, Jones N, Peck G et al (2019) Fire behaviour of modern façade materials—Understanding the Grenfell Tower fire. J Hazard Mater 368:115–123. https://doi.org/10.1016/j.jhazmat.2018.12.077

BRE Global Ltd (2020) Fire Performance of Cladding Materials Research. MHCLG Fire Performance of Cladding Materials Research: Final Report 1–14

Anderson J, Boström L, Chiva R et al (2020) European approach to assess the fire performance of façades. Fire Mater. https://doi.org/10.1002/fam.2878

EN-13823:2010+A1: 2014 (2014) Reaction to fire tests for building products—Building products excluding floorings exposed to the thermal attack by a single burning item. European Committee for Standardization

DIN:4102–1 (1998) Fire behaviour of building materials and elements, Part 1: Classification of building materials Requirements and testing. Building and Civil Engineering Standards Committee

Boström L, Hofmann-Böllinghaus A, Colwell S, et al (2018) Development of a European approach to assess the fire performance of facades. European Commission

Grayson S (2018) Letter to fire journal editors on materials identification in comparison of results among fire scaling and flammability studies. Fire Mater 42:581–582. https://doi.org/10.1002/fam.2642

Ren F, Hu L, Sun X (2019) Experimental investigation on lateral temperature profile of window-ejected facade fire plume with ambient wind. Fire Technol 55:903–913. https://doi.org/10.1007/s10694-018-0809-9

Koohkan M, Dréan V, Girardin B et al (2020) Reconstruction of the grenfell tower fire—thermomechanical analysis of window failure during the grenfell tower disaster. Fire Technol. https://doi.org/10.1007/s10694-020-00980-4

Nam S, Bill RG (2009) A new intermediate-scale fire test for evaluating building material flammability. J Fire Prot Eng 19:157–176. https://doi.org/10.1177/1042391508101994

Agarwal G (2017) Evaluation of the Fire Performance of Aluminum Composite Material (ACM) Assemblies using ANSI/FM 4880

White N, Delichatsios M, Ahrens M, Kimball A (2013) Fire hazards of exterior wall assemblies containing combustible components. MATEC Web Confer. https://doi.org/10.1051/matecconf/20130902005

Huang X (2018) Critical drip size and blue flame shedding of dripping ignition in fire. Sci Rep 8:16528. https://doi.org/10.1038/s41598-018-34620-3

Sun P, Lin S, Huang X (2020) Ignition of thin fuel by thermoplastic drips: an experimental study for the dripping ignition theory. Fire Saf J 115:103006. https://doi.org/10.1016/j.firesaf.2020.103006

Guillaume E, Fateh T, Dréan V et al (2019) Reconstruction of Grenfell Tower fire Part 1: lessons from observations and determination of work hypotheses. Fire Materi. https://doi.org/10.1002/fam.2766

Guillaume E, Dréan V, Girardin B et al (2019) Reconstruction of Grenfell Tower fire. Part 2: a numerical investigation of the fire propagation and behaviour from the initial apartment to the façade. Fire Mater fam. https://doi.org/10.1002/fam.2765

Guillaume E, Dréan V, Girardin B et al (2019) Reconstruction of Grenfell Tower fire Part 3—numerical simulation of the Grenfell Tower disaster: contribution to the understanding of the fire propagation and behaviour during the vertical fire spread. Fire Mater fam. https://doi.org/10.1002/fam.2763

Chen T, Yuen A, Yeoh G et al (2019) Fire risk assessment of combustible exterior cladding using a collective numerical database. Fire 2:11. https://doi.org/10.3390/fire2010011

Herzog T, Krippner R, Lang W (2012) Facade construction manual. Walter de Gruyter

Giunta d’Albani AW, de Kluiver LL, de Korte ACJ et al (2017) Mass loss and flammability of insulation materials used in sandwich panels during the pre-flashover phase of fire. Fire Mater 41:779–796. https://doi.org/10.1002/fam.2418

Collier PCR, Baker GB (2013) The influence of construction detailing on the fire performance of polystyrene insulated panels. Fire Technol 49:195–211. https://doi.org/10.1007/s10694-011-0238-5

Crewe RJ, Hidalgo JP, Sørensen MX et al (2018) Fire Performance of sandwich panels in a modified ISO 13784-1 small room test: the influence of increased fire load for different insulation materials. Fire Technol 54:819–852. https://doi.org/10.1007/s10694-018-0703-5

Morikawa T, Yanai E, Okada T et al (1993) Toxic gases from house fires involving natural and synthetic polymers under various conditions. Fire Saf J 20:257–274. https://doi.org/10.1016/0379-7112(93)90047-T

Čolić A, Pečur IB (2020) Influence of Horizontal and Vertical Barriers on Fire Development for Ventilated Façades. Fire Technol 56:1725–1754. https://doi.org/10.1007/s10694-020-00950-w

EN-13501 (2009) Fire classification of construction products and building elements. European Commission

Sandak A, Sandak J, Brzezicki M, Kutnar A (2019) Portfolio of Bio-Based Façade Materials. In: Bio-based Building Skin. Springer, Singapore, pp 155–177

Babrauskas V (2017) Engineering variables to replace the concept of ‘noncombustibility.’ Fire Technol 53:353–373. https://doi.org/10.1007/s10694-016-0570-x

Babrauskas V (2016) The Cone Calorimeter. In: Hurley M (ed) SFPE Handbook of Fire Protection Engineering. Springer, London, pp 952–980

Quintiere JG, Harkleroad MF (1984) New concepts for measuring flame spread properties. In: Fire Safety: Science and Engineering. ASTM International

Quintiere JG (2006) Fundamental of fire phenomena. Wiley, New York

Hidalgo JP, Torero JL, Welch S (2017) Experimental characterisation of the fire behaviour of thermal insulation materials for a performance-based design methodology. Fire Technol 53:1201–1232. https://doi.org/10.1007/s10694-016-0625-z

Simms DL (1963) On the pilot ignition of wood by radiation. Combust Flame 7:253–261. https://doi.org/10.1016/0010-2180(63)90190-1

Drysdale D (2011) An Introduction to Fire Dynamics, vol 3. Wiley, Chichester, UK

Luche J, Rogaume T, Richard F, Guillaume E (2011) Characterization of thermal properties and analysis of combustion behavior of PMMA in a cone calorimeter. Fire Saf J 46:451–461. https://doi.org/10.1016/j.firesaf.2011.07.005

Spearpoint MJ (1999) Predicting the ignition and burning rate of wood in the cone calorimeter using an integral model. University of Maryland, Maryland

Gollner MJ, Miller CH, Tang W, Singh AV (2017) The effect of flow and geometry on concurrent flame spread. Fire Saf J 91:68–78. https://doi.org/10.1016/j.firesaf.2017.05.007

Babrauskas V, Peacock DR (1992) Heat release rate: the single most important parameter in fire hazard. Fire Saf J 18:255–272

Huggett C (1980) Estimation of rate of heat release by means of oxygen consumption measurements. Fire Mater 4:61–65. https://doi.org/10.1002/fam.810040202

Krämer RH, Zammarano M, Linteris GT et al (2010) Heat release and structural collapse of flexible polyurethane foam. Polym Degrad Stab 95:1115–1122. https://doi.org/10.1016/j.polymdegradstab.2010.02.019

Lin S, Sun P, Huang X (2019) Can peat soil support a flaming wildfire? Int J Wildland Fire 28:601–613. https://doi.org/10.1071/WF19018

Chung YJ, Spearpoint M (2008) Combustion properties of native Korean wood species. Int J Eng Perform Based Fire Codes 9:118–125

Zhou X, Pizzi A, Sauget A et al (2013) Lightweight tannin foam/composites sandwich panels and the coldset tannin adhesive to assemble them. Ind Crops Prod 43:255–260. https://doi.org/10.1016/j.indcrop.2012.07.020

Ferdous W, Manalo A, Aravinthan T (2017) Bond behaviour of composite sandwich panel and epoxy polymer matrix: Taguchi design of experiments and theoretical predictions. Constr Build Mater 145:76–87. https://doi.org/10.1016/j.conbuildmat.2017.03.244

Her SC (1999) Stress analysis of adhesively-bonded lap joints. Compos Struct 47:673–678. https://doi.org/10.1016/S0263-8223(00)00052-0

Vekhter I, Varma CM (2003) Proposal to determine the spectrum of pairing glue in high-temperature superconductors. Phys Rev Lett 90:4. https://doi.org/10.1103/PhysRevLett.90.237003

Banea MD, Da Silva LFM, Campilho RDSG (2012) Effect of temperature on tensile strength and mode i fracture toughness of a high temperature epoxy adhesive. J Adhes Sci Technol 26:939–953. https://doi.org/10.1163/156856111X593649

Goudarzi M, Ghanbari D, Salavati-Niasari M, Ahmadi A (2016) Synthesis and characterization of Al(OH)3, Al2O3 nanoparticles and polymeric nanocomposites. J Cluster Sci 27:25–38. https://doi.org/10.1007/s10876-015-0895-5

Alavi MA, Morsali A (2010) Syntheses and characterization of Mg(OH)2 and MgO nanostructures by ultrasonic method. Ultrason Sonochem 17:441–446. https://doi.org/10.1016/j.ultsonch.2009.08.013

Bourbigot S, Duquesne S (2007) Fire retardant polymers: Recent developments and opportunities. J Mater Chem 17:2283–2300. https://doi.org/10.1039/b702511d

Kobayashi Y, Huang X, Nakaya S et al (2017) Flame spread over horizontal and vertical wires: the role of dripping and core. Fire Saf J 91:112–122. https://doi.org/10.1016/j.firesaf.2017.03.047

Li K, Mousavi M, Hostikka S (2017) Char cracking of medium density fibreboard due to thermal shock effect induced pyrolysis shrinkage. Fire Saf J 91:165–173. https://doi.org/10.1016/j.firesaf.2017.04.027

Li K, Hostikka S, Dai P et al (2017) Charring shrinkage and cracking of fir during pyrolysis in an inert atmosphere and at different ambient pressures. Proc Combust Inst 36:3185–3194. https://doi.org/10.1016/j.proci.2016.07.001

Cooke GME (1987) The structural response of steel I-section members subject to elevated temperature gradients across the section. City University, London

Wang S, Ding P, Lin S et al (2020) Deformation of wood slice in fire: Interactions between heterogeneous chemistry and thermomechanical stress. Proc Combust Inst. https://doi.org/10.1016/j.proci.2020.08.060

Innes A, Innes J (2011) Flame Retardants. In: Applied Plastics Engineering Handboo. William Andrew Publishing, pp 469–485

Kumar S, Singh RK (2013) Thermolysis of high-density polyethylene to petroleum products. J Petrol Eng 2013:1–7. https://doi.org/10.1155/2013/987568

Bilton M, Brown AP, Milne SJ (2012) Investigating the optimum conditions for the formation of calcium oxide, used for CO2 sequestration, by thermal decomposition of calcium acetate. J Phys Conf Ser. https://doi.org/10.1088/1742-6596/371/1/012075

Acknowledgments

This research is funded by the National Natural Science Foundation of China (No. 51876183) and Hong Kong Polytechnic University Emerging Frontier Area (EFA) Scheme of RISUD (P0013879). The authors thank Prof. Jose Torero (University College London) for inspiring this research.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary material 1 (AVI 5707 kb)

Supplementary material 2 (AVI 8256 kb)

Supplementary material 3 (AVI 7517 kb)

Supplementary material 4 (AVI 6063 kb)

Appendix

Appendix

There are various standard methods to test cladding materials or metal composite panels are used, e.g. ASTM E-84 in USA with the guidelines of test methods in NFPA 285 and BS 8414-1 in the UK, as listed in Table 3

.

Tables 4,5 and 6 list the details of the classification for material in EN 13501-1.

Note that these tables only show the grading of materials widely found in marketing literature based on their combustibility and flammability. It is not the authors’ intention to praise or critize any standard test. The authors encourage the readers to refer to the relevant standard and testing methods and check for more details in the references.

The thermal analysis of A2 and B core materials was conducted under argon gas flow at two heating rates of 10 and 20 K/min, respectively. The initial mass for testing was about 10 mg. Figure 8 shows the normalized mass loss and mass-loss rate (%/min) of A2 core and B core varying with temperature.

For these two panel core materials, there are several local peaks of the mass-loss rate at different temperatures due to the evaporation of glue and the thermal decomposition of Al(OH)3 (180–200°C) [71], Mg(OH)2 (~ 330 °C) [71], PE (~ 370–450 °C) [72], ethylene-vinyl acetate (EVA at ~ 350 °C), and CaCO3 (~ 750 °C) [73]. Comparatively, A2 core material has more fire retardants and less flammable PE than the B2 core material. The total mass loss of A2 core (< 40%) is also smaller than that of B core (about 55%). Both material-level aspects suggested that the B core is more flammable than the A2 core.

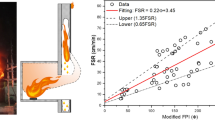

Based on the principle of oxygen calorimetry, the heat release rate per unit area (HRRPUA) can be calculated to quantify the flame intensity and the fire hazards. Figure 9 shows the HRRPUA evolution of A2-core and B-core ACPs under two different irradiations of 40 kW/m2 and 50 kW/m2, where the ignition and flame extinction moments are highlighted. Once the core material is ignited, the heat release rate dramatically increases and subsequently reaches its peak value. Afterward, the flame intensity gradually decreases and eventually extinguishes after several minutes. Then, the fire is sustained in the form of smoldering combustion until burnout. Compared to A2-core panel, B2-core panel has a larger peak HRRPUA and a longer ignition time, but the flame can sustain for a shorter period (see more detailed comparisons in Fig. 5).

Rights and permissions

About this article

Cite this article

Khan, A.A., Lin, S., Huang, X. et al. Facade Fire Hazards of Bench-Scale Aluminum Composite Panel with Flame-Retardant Core. Fire Technol 59, 5–28 (2023). https://doi.org/10.1007/s10694-020-01089-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10694-020-01089-4