Abstract

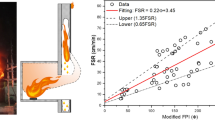

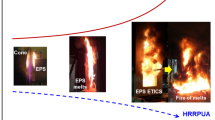

External Thermal Insulation Composite System (ETICS) facades with expanded polystyrene (EPS) insulation and thin rendering are applied frequently in buildings. Considering high combustibility of EPS, with these facades concerns also arise regarding spread of a possible fire between neighbouring compartments of high-rise buildings. Fire tests of two large-scale facades were performed to study two parameters presumably influencing significantly the fires of such facades in real-life settings, i.e. incident heat flux upon the facade’s surface (IHFFS) and damage of the facade’s render (the latter being a consequence of poor or unfinished construction work, ageing or fire-induced thermal strain). The first facade was rendered fully and was exposed to moderately-fast increasing IHFFS. In the second (partially unrendered) facade case the IHFFS progressed faster. The facade flame body (temperatures and shape) was monitored by thermocouples, photo and video cameras. For detection of melting of EPS and internal burning, thermocameras were used within the facades areas outside the visible plume. In the plume zone, however, a group of thermocouples was embedded inside EPS and the shapes (plateaus and slopes) of the collected time-temperature graphs were observed for these purposes. The IHFFS imposed on the facades during fire testing were estimated by numerical calculations. In both cases the first pronounced render crack was evolved at the estimated average between-windows IHFFS of around 30 kW/m\(^2\) and was followed by internal burning of EPS. While the latter did not seem to spread across the facade for the fully-rendered facade, a fast fire spread was detected for the second specimen.

Similar content being viewed by others

Notes

The term ‘render’ (or ‘rendering’) in this paper refers to a group of layers comprising thin external render, primer, and reinforcement mesh with base coating.

The terms ‘deformable’ and ‘cracking’ apply to cracks in the render being a consequence of facade damage, poor or unfinished construction of the facade, or of thermal strains of the render induced in fire.

Following the technical sheets of the supplier, the surfaces of the EPS blocks were not covered by the adhesive entirely but this was only applied over a part of the EPS/concrete contact surface (Figure 5d).

The term ‘voids’ refers to the gaps along the EPS/concrete wall interface and along the interfaces between individual EPS blocks where no adhesive was applied (Figure 5d). These gaps progressed during the test due to penetration of hot gases along them and consequential shrinking and melting of the neighbouring EPS. In addition, the term voids also refers to the gaps inside the insulation itself established after release of the blowing agent and shrinking of the EPS (normally observed around the EPS temperature of 80\(^{\circ }\)C).

The escaping gaseous mixture obtained in this figure could partially also be a consequence of escaping vapour from concrete walls.

References

Hakkarainen T, Oksanen T (2000) Fire safety assessment of wooden facades. Fire Mater 26:7–27

Klopovic S, Turan OF (2001) A comprehensive study of externally venting flames—part I: experimental plume characteristics for through-draft and no-through-draft ventilation conditions and repeatability. Fire Saf J 36:99–133

Klopovic S, Turan OF (2001) A comprehensive study of externally venting flames—part II: plume envelope and centre-line temperature comparisons, secondary fires, wind effects and smoke management system. Fire Saf J 36:135–172

Hokugo A, Hasemi Y, Hayashi Y, Yoshida M (2000) Mechanism for the upward fire spread through balconies based on an investigation and experiments for a multi–story fire in high–rise apartment building. In: Fire safety science—proceedings of sixth international symposium, international association for fire safety science

Suzuki T, Sekizawa A, Yamada T, Yanai E, Satoh H, Kurioka H, Kimura Y (2000) An Experimental study of ejected flames of a high-rise building—effects of depth of balcony on ejected flames. In: Proceedings of the fourth Asia–Oceania symposium of fire science and technology. International Association for Fire Safety Science

Lu KH, Hu LH, Tang F, He LH, Zhang XC, Qiu ZW (2014) Experimental investigation on window ejected facade flame heights with different constraint side wall lengths and global correlation. Int J Heat Mass Tran 78:17–24

Tang F, Hu LH, Delichatsios MA, Lu KH, Zhu W (2012) Global behaviors of enclosure fire and facade flame heights in normal and reduced atmospheric pressures at two altitudes. Int J Heat Mass Tran 56:119–126

Hu LH, Tang F, Delichatsios MA, Lu KH (2013) A mathematical model on lateral temperature profile of buoyant window spill plume from a compartment fire. Int J Heat Mass Tran 56:447–453

Chow WK, Hung WY (2006) Effect of cavity depth on smoke spreading of double-skin facade. Build Environ 41:970–979

Chow WK, Hung WY, Gao Y, Zou G, Dong H (2007) Experimental study on smoke movement leading to glass damages in double-skinned facade. Construct Build Mater 21:556–566

Chow CL (2011) Numerical studies on smoke spread in the cavity of a double-skin facade. J Civ Eng Manag 17:371392

Chow CL (2013) Full-scale burning tests on double-skin facade fires. Fire Mater 37:17–34

Oleszkiewicz I (1990) Fire exposure to exterior walls and flame spread on combustible cladding. Fire Technol 26:357–375

Johannesson P, Larsson G (1958) Fire tests with light non-bearing external walls. Swedish National Testing and Research Institute, Stockholm

Ondrus J, Petterson O (1986) Fire hazards of facades with externally applied additional thermal insulation—full scale experiments. Report LUTVDG/(TVBB–3025). Lund Institute of Technology, Lund

McGuire JH (1967) The flammability of exterior claddings. Fire Technol 3:137–141

Nishio Y, Yoshioka H, Noguchi T, Ando T, Tamura M (2013) Experimental study on fire propagation over combustible exterior facades in Japan. 1st international seminar for fire safety of facades, MATEC web of conferences 9: 04001

Xin H, Zhaopeng N, Lei P, Ping Z (2013) Experimental study of fire barriers preventing vertical fire spread in ETICs. 1st international seminar for fire safety of facades, MATEC web of conferences 9: 04003

Oleszkiewicz I (1991) Vertical separation of windows using spandrel walls and horizontal projections. Fire Technol 27:334–340

EOTA (2013) N073 technical report—large scale fire performance testing of external wall cladding systems. European Organisation for Technical Assessment, Brussels

ISO, DIS 13785-1 (2000) Reaction-to-fire tests for facades-part 1: intermediate-scale tests. International Organization for Standardization, Geneva

ISO, DIS 13785–2 (2000) Reaction-to-fire tests for facades-part 2: large-scale tests. International Organization for Standardization, Geneva

Babrauskas V (1996) Facade fire tests: towards an international test standard. Fire Technol 32:219–230

Smolka M, Messerschmidt B, Scott J, le Madec B (2013) Semi-natural test methods to evaluate fire safety of wall claddings. 1st international seminar for fire safety of facades, MATEC web of conferences 9: 02012

Antonatus E (2013) Fire safety of etics with EPS material properties and relevance for fire safety during transport, construction and under end use conditions in external thermal insulation component systems. 1st international seminar for fire safety of facades, MATEC web of conferences 9: 02008

Dragsted A, Vestergaard AB (2013) A new approach to the Danish guidelines for fire protection of combustible insulation. 1st international seminar for fire safety of facades, MATEC web of conferences 9: 01001

Yan Z, Zhao C, Liu Y, Deng X, Ceng X, Liu S, Lan B, Nilsson R, Jeansson S (2013) Experimental study and advanced CFD simulation of fire safety performance of building external wall insulation system. 1st international seminar for fire safety of facades, MATEC web of conferences 9: 03005

White N, Delichatsios M, Ahrens M, Kimball A (2013) Fire hazards of exterior wall assemblies containing combustible components. 1st international seminar for fire safety of facades, MATEC web of conferences 9: 02005

Mikkola E, Hakkarainen T, Matala A (2013) Fire safety of EPS insulated facades in residential multi-storey buildings. 1st international seminar for fire safety of facades, MATEC web of conferences 9: 04002

Jansson R, Anderson J (2012) Experimental and numerical investigation of fire dynamics in a facade test rig. In: Proceedings of fire computer modeling, Santander, Spain, 18–19th October 2012

Flory PJ (1953) Principles of polymer chemistry. cornell university press, Ithaca

Gaur U, Wunderlich B (1982) Heat capacity and other thermodynamic properties of linear macromolecules v. polystyrene. J Phys Chem Ref Data 11:313–325

Varma-Nair M, Wunderlich B (1991) Heat capacity and other thermodynamic properties of linear macromolecules X. Update of the ATHAS 1980 Data Bank. J Phys Chem Ref Data 20:349–404

SFPE Handbook of Fire Protection Engineering (1995) National Fire Protection Association. One Batterymarch Park, Quincy

Martins CR, Ruggeri G, De Paoli MA (2003) Synthesis in pilot plant scale and physical properties of sulfonated polystyrene. J Braz Chem Soc 14:797–802

Kuhn MCA, da Silva JL, Casagrande ACA, Casagrande OL Jr (2008) Styrene polymerization by nickel and titanium catalysts based on Tris(pyrazolyl)borate ligands. J Braz Chem Soc 19:1560–1566

Peterson JD, Vyazovkin S, Wight CA (2001) Kinetics of the thermal and thermo-oxidative degradation of polystyrene, polyethylene and poly(propylene). Macromol Chem Phys 202:775–784

Stoliarov SI, Walters RN (2008) Determination of the heats of gasification of polymers using differential scanning calorimetry. Polymer Degrad Stabil 93:422–427

Shi L, Chew MYL (2013) A review of fire processes modeling of combustible materials under external heat flux. Fuel 106:30–50

FDS Version 5; User’s guide (2007) National Institute of Standards and Technology, Gaithersburg

ABAQUS CFD, version 6.12; documentation, (2012) DS-Simulia, Providence. R.I. AISC, Rhode Island, United States

ANSYS CFX Release 14.0; documentation (2011) Ansys Inc., Cecil Township

ANSYS Fluent Release 12.0; documentation (2009) Fluent Inc., Cecil Township

EN 13823:2010, (2010) Reaction to fire tests for building products building products excluding floorings exposed to the thermal attack by a single burning item. European Committee for Standardization, Brussels

Zhang J, Delichatsios M, Colober M (2010) Assessment of fire dynamics Simulator for heat flux and flame heights predictions from fires in SBI tests. Fire Technol 46:291–306

EN 13501-1+A1 (2009) Fire classification of construction products and building elements—part 1: classification using test data from reaction to fire tests. European Committee for Standardization, Brussels

Babrauskas V (2006) Effective heat of combustion for flaming combustion of conifers. Can J For Res 36:659663

FTP Code: International Code for Application of Fire Test Procedures (1998) International Maritime Organization, London, UK

Narayanan N, Ramamurthy K (2000) Structure and properties of aerated concrete: a review. Cement Concr Compos 22:321–329

McElroy DL, Kimpflen JF (eds) (1990) Insulation materials, testing, and applications. American Society for Testing and Materials, Baltimore

Eurocode 2 (2004) Design of concrete structures, part 1.2: structural fire design. European Committee for Standardization, Brussels

Matala A (2008) Estimation of solid phase reaction parameters for fire simulation. Master’s thesis, Helsinki University of Technology, Helsinki

Buchanan AH (ed) (1994) Fire engineering design guide. Centre for Advanced Engineering, University of Canterbury, Christchurch

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hajduković, M., Knez, N., Knez, F. et al. Fire Performance of External Thermal Insulation Composite System (ETICS) Facades with Expanded Polystyrene (EPS) Insulation and Thin Rendering. Fire Technol 53, 173–209 (2017). https://doi.org/10.1007/s10694-016-0622-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10694-016-0622-2