Abstract

Finite-element (FE) analysis was used to compare the high-temperature responses of steel columns with two different stress–strain models: the Eurocode 3 model and the model proposed by National Institute of Standards and Technology (NIST). The comparisons were made in three different phases. The first phase compared the critical buckling temperatures predicted using forty-seven column data from five different laboratories. The slenderness ratios varied from 34 to 137, and the applied axial load was 20% to 60% of the room-temperature capacity. The results showed that the NIST model predicted the buckling temperature as or more accurately than the Eurocode 3 model for four of the five data sets. In the second phase, thirty unique FE models were developed to analyze the W8 × 35 and W14 × 53 column specimens with the slenderness ratio about 70. The column specimens were tested under steady-heating conditions with a target temperature in the range of 300°C to 600°C. The models were developed by combining the material model, temperature distributions in the specimens, and numerical scheme for non-linear analyses. Overall, the models with the NIST material properties and the measured temperature variations showed the results comparable to the test data. The deviations in the results from two different numerical approaches (modified Newton–Raphson vs. arc-length) were negligible. The Eurocode 3 model made conservative predictions on the behavior of the column specimens since its retained elastic moduli are smaller than those of the NIST model at elevated temperatures. In the third phase, the column curves calibrated using the NIST model was compared with those prescribed in the ANSI/AISC-360 Appendix 4. The calibrated curve significantly deviated from the current design equation with increasing temperature, especially for the slenderness ratio from 50 to 100.

Similar content being viewed by others

References

ECS (2005) Eurocode 3: Design of steel structures. General rules. Structural fire design. Standard EN 1993-1-2, European Committee for Standardization.

AISC (2010) Specification for structural steel buildings. ANSI/AISC 360-10 American Institute of Steel Construction, Chicago.

NIST (2005) Federal building and fire safety investigation of the World Trade Center disaster: Mechanical properties of structural steel. Technical Report NCSTAR 1-3D. National Institute of Standards and Technology.

NIST (2008) Final Report on the Collapse of World Trade Center Building 7. Federal Building and Fire Safety Investigation of the World Trade Center Disaster. NIST NCSTAR 1A. National Institute of Standards and Technology.

NIST (2011) High-temperature tensile constitutive data and models for structural steels in fire. NIST Technical Note 1714. National Institute of Standards and Technology.

ASTM International (2009) Standard test methods for elevated temperature tension tests of metallic materials. Standard E21-09. ASTM International, West Conshohocken. doi:10.1520/E0021-09.

ISO (1999) Metallic materials-tensile testing at elevated temperature. Standard 783:1999. International Organization for Standardization.

ISO (2011) Metallic materials—tensile testing—Part 2: Method of test at elevated temperature. Standard 6892-2:2011. International Organization for Standardization.

ASTM International (2014) Standard specification for structural bolts, steel, heat treated, 120/105 ksi minimum tensile strength. Standard A325-14. ASTM International, West Conshohocken.

ASTM International (2014) Standard specification for structural bolts, alloy steel, heat treated, 150 ksi minimum tensile strength. Standard A490-14a, ASTM International, West Conshohocken.

ASTM International (2014) Standard specification for high-yield-strength, quenched and tempered alloy steel plate, suitable for welding. Standard A514/A514M-14. ASTM International, West Conshohocken.

ASTM International (2014) Standard specification for structural steel with improved yield strength at high temperature for use in buildings. Standard A1077/A1077 M-14. ASTM International, West Conshohocken.

Zhang C, Li GQ, Wang, YC (2012) Predictability of buckling temperature of axially loaded steel columns in fire. J Constr Steel Res. 75:32–37.

Ali FA, Shepherd P, Randall M, Simms IW, O’Connor DJ, Burgess I (1998) Effect of axial restraint on the fire resistance of steel columns. J Constr Steel Res, 46(1–3):305–306.

Franssen J, Schleich JB, Cajot LG, Azpiazu W (1996) A simple model for the fire resistance of axially loaded members—comparison with experimental results. J Constr Steel Res, 37(3):175–204.

Azpiazu W, Unanue JA (1993) Buckling curves for hot rolled H profiles submitted to fire. Report 97.798-0-ME/V. LABEIN, Bilbao.

Franssen J, Talamona D, Kruppa J, Cajot L (1998) Stability of steel columns in case of fire: experimental evaluation. J Struct Eng 124(2):158–163.

Lie TT, Macauley BA (1989) Evaluation of the fire resistance of protected steel columns. Internal Report IRC-IR-583. Institute for Research in Construction. National Research Council Canada.

ASTM International (2014) Standard test methods for fire tests of building construction and materials. Standard E119-14, West Conshohocken.

Tan KH, Toh WS, Huang ZF, Phng GH (2007) Structural responses of restrained steel columns at elevated temperatures. Part 1: experiments. Eng Struct. 29(8):1641–1652.

Wang YC, Davies JM (2003) Fire tests of non-sway loaded and rotationally restrained steel column assemblies. J Constr Steel Res. 59(3):359–383.

ANSYS (2012) ANSYS User Manual Version 14.0.

Choe L (2011) Structural mechanics and behavior of steel members under fire loading. Ph.D. Thesis. Purdue University, West Lafayette.

Choe L, Luecke W, Gross J (2014) A comparison of two temperature-dependent stress-strain models for structural steel under transient heating condition. In: 8th International Conference on Structures in Fire. Shanghai, China.

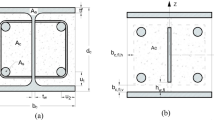

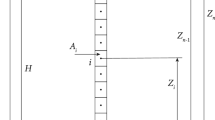

Choe L, Varma AH, Agarwal A, Surovek, A (2011) Fundamental behavior of steel beam-columns and columns under fire loading: an experimental evaluation. J Struct Eng ASCE 137:954.

ABAQUS (2012) ABAQUS/Standard Version 6.12 User’s Manuals: Volume I–III, Hibbitt, Karlsson, and Sorenson Inc. Pawtucket.

Agarwal A, Varma, A. H. (2014) Fire induced progressive collapse of steel building structures: The role of interior gravity columns. Eng Struct 58:129–140.

Ziemian RD (ed) (2010) Guide to stability design criteria for metal structures, Wiley, Hoboken.

NIST (2010) Best practice guidelines for structural fire resistance design of concrete and steel buildings. NIST Technical Note 1681. National Institute of Standards and Technology, Gaithersburg.

Takagi J, Deierlein GG (2007) Strength design criteria for steel members at elevated temperatures. J Constr Steel Res. 63(8):1036–50.

NIST (2016) Temperature-dependent material modeling for structural steels: formulation and application. NIST Technical Note 1907. National Institute of Standards and Technology. doi: 10.6028/NIST.TN.1907.

Acknowledgments

Valuable comments and input on this work were provided by Joseph Main, Matthew Bundy, Anthony Hamins, Ramesh Selvarajah, and Fahim Sadek of National Institute of Standards and Technology are gratefully acknowledged.

Disclaimers

Certain commercial entities, equipment, products, or materials are identified in this document in order to describe a procedure or concept adequately. Such identification is not intended to imply recommendation, endorsement, or implication that the entities, products, materials, or equipment are necessarily the best available for the purpose. The policy of the National Institute of Standards and Technology (NIST) is to include statements of uncertainty with all NIST measurements. In this document, however, measurements of authors outside of NIST are presented, for which uncertainties were not reported and are unknown.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

The general equation (Eq. A1) of the NIST true stress–true strain (σ–ɛ) model for steel accounts for temperature dependence of elastic modulus, yield strength, strain-hardening behavior, and strain sensitivity. The model was developed from a survey of many reported values of high-temperature structural steel behavior. The NIST technical report [31] contains supporting data, details of regression analyses and approaches, and estimates of the uncertainties in the fitted parameters.

where T is temperature, E is temperature-dependent steel modulus (Eq. A2), R is retained yield strength (Eq. A3), ɛ′/ɛ 0 ′ is normalized strain rate, and m is strain-rate sensitivity (Eq. A4).

1.1 Elastic Modulus

The decrease in elastic modulus with increasing temperature was taken from reported literature data from tensile tests of structural steel.

where E 0 is the elastic modulus at T = 20°C, and T * = T − 20°C in °C. The elastic modulus function decays smoothly from room temperature.

1.2 Yield Strength Behavior

The normalized retained yield strength, R, as a function of temperature for 42 individual structural steels from 16 different literature sources described in [3].

Like the elastic modulus, it decays smoothly from the room-temperature value to a small minimum value with increasing temperature. The parameters of the equation were specially chose to have the greatest fidelity to the reported literature data in the range (400 < T < 650)°C.

1.3 Yield Strength Dependence of the Strain Hardening

For structural steel, the amount of strain hardening after yield generally decreases with increasing room-temperature yield strength. The parameters of the strain hardening behavior (k 1, k 2, k 3, k 4 and n) were determined by a non-linear regression of the stress–strain curves of eight different structural steels taken from the NIST WTC investigation [3]. This form joins the elastic portion of the stress strain curve.

1.4 Temperature Dependence of the Strain-Rate Sensitivity

The strain-rate sensitivity, m, of structural steels is nearly zero at room temperature and increases to a maximum at high temperature.

Table 6 shows the values of the individual parameters in Eq. A1 for various structural steels. All were developed from literature data that had been evaluated for completeness and quality.

Rights and permissions

About this article

Cite this article

Choe, L., Zhang, C., Luecke, W.E. et al. Influence of Material Models on Predicting the Fire Behavior of Steel Columns. Fire Technol 53, 375–400 (2017). https://doi.org/10.1007/s10694-016-0568-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10694-016-0568-4