Absrtract

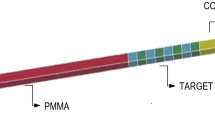

In this paper, a framework is presented for the modeling of the response of structural composites subjected to combined mechanical loading and fire. An emphasis is placed on the response of composites at temperatures below the decomposition temperature, where the viscoelastic response of the composite material becomes important. Material property characterization results are presented for an E-glass reinforced vinyl ester composite typical of that used for naval ship applications. Time-temperature equivalence is used in a compression strength model to predict the time to failure of composites subjected to isothermal compression loading (compression creep rupture failure). These predictions are compared with experimentally determined times to failure with good agreement. In particular, shift factors obtained from shear compliance testing are able to collapse the compression creep rupture data at different temperatures, indicating that viscolelasticity is the dominant mechanism driving the failure. This model is combined with a standard diffusion model for heat transfer in the composite to predict the time-dependent failure of composites subjected to simultaneous one-sided heat flux and compression loading. Predicted times to failure are compared with experimental results with good agreement.

Similar content being viewed by others

References

McGrattan K, Hostikka S, Floyd J (2007) Fire Dynamics Simulator (Version 5) User’s Guide. National Institute of Standards and Technology Special Publication 1019-5. http://fds-smv.googlecode.com/svn/trunk/FDS/trunk/Manuals/All_PDF_Files/FDS_5_User_Guide.pdf. Accessed December 15, 2009

Budiansky B, and Fleck NA (1993). “Compressive Failure Of Fiber Composites.” J. Mech. Phys. Solids, 41(1), 183-211

http://www.hotdiskinstruments.com/home/technology.html. Accessed December 15, 2009

Log T, and Gustafsson SE (1995). “Transient Plane Source (TPS) Technique for Measuring Thermal Transport Properties of Building Materials.” Fire and Materials, 19, 43-49

Lattimer BY, Ouellette J (2006) Properties of composite materials for thermal analysis involving fires. Compos A Appl Sci Manuf 37(7):1068–1081

Lattimer B, Ouellette J, and Sorathia U (2004) Large-scale fire resistance tests on sandwich composites. SAMPE, Long Beach, CA

Schapery RA (1966) A theory of non-linear thermoviscoelasticity based on irreversible thermodynamics. Proc 5th US Nat Cong Appl Mech, ASME 511-530

Schapery RA (1969). “On the Characterization of Nonlinear Viscoelastic Materials.” Polym. Eng. Sci., 9(4), 295-310

Lou YC, and Schapery RA (1971). “Viscoelastic Characterization of a Nonlinear Fiber-Reinforced Plastic.” Journal of Composite Materials, 5, 208-234

Peretz D (1982). “Non-Linear Viscoelastic Characterization Of Fm-73 Adhesive.” J. Rheol., 26(3), 245-261

Tuttle ME, and Brinson HF (1986). “Prediction Of The Long-Term Creep Compliance Of General Composite Laminates.” Exp. Mech., 26(1), 89-102

Xiao X (1989). “Studies Of The Viscoelastic Behavior Of A Thermoplastic Resin Composite.” Compos. Sci. Technol., 34(2), 163-182

Xiao XR, Hiel CC, and Cardon AH (1994). “Characterization And Modeling Of Nonlinear Viscoelastic Response Of Peek Resin And Peek Composites.” Compos. Eng., 4(7), 681-702

Tuttle ME, Pasricha A., and Emery AF (1995). “The Nonlinear Viscoelastic-Viscoplastic Behavior Of Im7/5260 Composites Subjected To Cyclic Loading.” Journal Of Composite Materials, 29(15), 2025-2046

Peretz D, and Weitsman Y (1983). “The Non-Linear Thermoviscoelastic Characterizations Of Fm-73 Adhesives.” J. Rheol., 27(2), 97-114

Ferry JD (1980) Viscoelastic properties of polymers, 3rd edn. John Wiley and Sons, New York

Guedes RM, Morais JJL, Marques AT, and Cardon AH (2000). “Prediction of long-term behaviour of composite materials.” Comput. Struct., 76(1-3), 183-194

Crissman JM, and Zapas LJ (1985). On The Mechanical Preconditioning Of Ultrahigh-Molecular-Weight Polyethylene At Small Uniaxial Deformations.” J. Polym. Sci. Pt. B-Polym. Phys., 23(12), 2599-2610

Pasricha A, Tuttle ME, and Emery AF (1996). “Time-dependent response of IM7/5260 composites subjected to cyclic thermo-mechanical loading.” Compos. Sci. Technol., 56(1), 55-62

Bausano JV, Lesko JJ, and Case SW (2006). Composite life under sustained compression and one sided simulated fire exposure: Characterization and prediction. Composites Part A: Applied Science and Manufacturing, 37(7), 1092-1100

Leaderman H (1958). In: Eirich FR (ed), Rheology. Academic Press, New York

Boyd SE, Lesko JJ, and Case SW (2007). “Compression Creep Rupture Behavior of a Glass/vinyl ester Composite Laminate Subject to Fire Loading Conditions.” Composites Science and Technology, 67(15-16), 3187-3195

Hiel C, Cardon AH, and Brinson HF (1984) Nonlinear viscoelastic response of resin matrix composite laminates, NASA Contractor Report. NASA Cr. 149 p

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Boyd, S.E., Bausano, J.V., Case, S.W. et al. Mechanistic Approach to Structural Fire Modeling of Composites. Fire Technol 47, 941–983 (2011). https://doi.org/10.1007/s10694-009-0122-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10694-009-0122-8