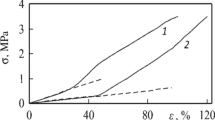

The effect of the technology of roll calender processing of nonwoven needle-punched fabric based on a blend of polymer and bicomponent fibers on the correlation between the decrease of porosity and the tensile strength of the processed materials is investigated. The characteristics of fabric processing on roll calender are studied. A method is proposed for loading the calender, in which the time of contact of the fabric with the heated rollers increases. The porosity of the fabric decreases steadily with decrease of the gap between the rollers, whereupon the tensile strength of the material reaches the maximum at a particular gap between the rollers.

Similar content being viewed by others

References

A.V. Dedov and V.G. Nazarov, Fibre Chemistry, 43, No. 3, 259-262 (2011).

F. Jianyong and Z. Jianchun, Nonwoven Textile Res. J., 83, 2191-2203 (2013).

A.V. Dedov and V.G. Nazarov, Fibre Chemistry, 47, No. 2, 121-125 (2015).

S. Sakthivel, J.J. Ezhil-Anban, and T. Ramachandran, J. Eng. Fibers a. Fabrics, 9, No.1, 149-155 (2014).

Z.S. Abdel-Rehim, M.M. Saad, et al., AUTEX Res. J., 6, No. 3, 148-616 (2006).

M. Tascant and A.E. Vaughn, Text. Res. J, 78, No. 1, 289-296 (2008).

N.I.T. Hamirpur and S.S. Saleh, J. Basic. Appl. Sci. Res., 1, No. 12, 3513-3524 (2011).

S. Debnath, Indian J. Fibre a. Text. Res., 36, No. 6, 122-131 (2011).

S. Sakthivel and T. Ramachandran, Intern. J. Eng. Res. a. Appl. (IJERA), 2, No. 3, 2983-2987 (2012). 10. S. Zobel, B. Maze, et al., Chem. Eng. Sci., 62, 6285-6291 (2007).

A.V. Dedov, Khim. Volokna, No. 2, 52-54 (2008).

12. A.V. Dedov, Intern. Polymer Sci. a. Technol., 38, No. 9, 33-36 (2011).

13. X. Cui, Adv. Materials Res., 864-867, 605-612 (2014).

K. Dragana, S. Zenun, and Mi. Budimir, J. Fiber Bioeng. a. Inform., 7, No. 1, 1-11 (2014).

15. D. Kopitar, Z. Skenderi, and T. Rukavina, Text. Res. J., 84, No. 1, 69-80 (2014).

A.V. Dedov, V.G. Nazarov, et al., Khim. Volokna, No. 5, 56-58 (2001).

K.E. Perepelkin, Ros. Khim. Zh., XL VI, No. 2, 18-26 (2002). 1

18. M. Dasdemir, B. Maze, and N. Anantharamaiah, J. Materials Sci., 46, No. 10, 3269-3281 (2011).

V.M. Gorchakova, A.P. Sergeenkov, and T.E. Voloshchik, Equipment for Production of Nonwovens, Pt. 1 [in Russian], A.N. Kosygin Moscow State Technological University, Moscow (2006), p. 648.

A.V. Dedov, V.G. Nazarov, et al., Khim. Volokna, No. 1, 33-36 (2001).

The work was carried with the financial support of the Moscow Polytechnic University under the V.E. Fortov Grant “Nonwovens Based on Modified Synthetic Fibers.”

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskie Volokna, No. 4, pp. 34-36, July-August 2022

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nazarov, V.G., Dedov, A.V. & Evdokimov, A.G. Nonwoven Needle-Punched Materials with High Tensile Strength. Fibre Chem 54, 248–251 (2022). https://doi.org/10.1007/s10692-023-10387-w

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10692-023-10387-w