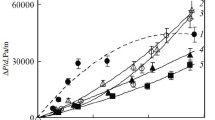

The influence of the processing rate of nonwoven needle-punched fabrics made of polyethylene terephthalate and bicomponent fibres of different surface density on air filtration has been investigated. The dependences of the air filtration rate on the pressure drop for fabrics with a surface density of 0.2 and 0.37 kg/m2 and processed materials based on them are nonlinear. The change in the parameters of air filtration in materials obtained by varying the processing rate depends on the surface density of the fabrics. When processing a fabric with a surface density of 0.2 kg/m2, materials in which the filtration resistance and air flow modes correspond to the characteristics of the flow in the fabric were obtained. At a processing rate of 5 and 10 m/min of a fabric with a surface density of 0.37 kg/m2, materials in which, compared to the fabric, the filtration resistance increases with the transition to a laminar air flow were obtained. A decrease in the processing rate from 5 to 1.2 m/min leads to the production of a material the filtration resistance of which approaches the filtration resistance of the original fabric.

Similar content being viewed by others

References

A. V. Dedov and V. G. Nazarov, “Processed nonwoven needlepunched materials with increased strength,” Fibre Chem., 47, No. 2, 121-125 (2015).

A. V. Dedov and V. G. Nazarov, “Mechanical properties of composite materials based on latex-impregnated needle-punched nonwoven fabrics made of fibres of different chemical nature,” Materialovedenie, No. 4, 28-33 (2017).

A. V. Dedov, B. A. Roev, et al., “Mechanism of stretching and breaking of needle-punched nonwovens,” Fibre Chem., 49, No. 5, 334-337 (2018).

A. V. Dedov, “Needle-punched material with density gradient over its thickness,” Materialovedenie, No. 6, 32-35 (2008).

E. Ayad, A. Cayla, et al., “Influence of rheological and thermal properties of polymers during melt spinning on bicomponent fiber morphology,” J. Mater. Eng. Perform., 25, No. 8, 3296-3302 (2016).

C. Prahsarn, W. Klinsukhon, et al., “Hollow segmented-pie PLA/PBS and PLA/PP bicomponent fibers: an investigation on fiber properties and splittability,” J. Mater. Sci., 51, No. 24, 10910-10916 (2016).

W. Huang, D. Liu, et al., “Polymer complexation for functional fibers,” Sci. China Technol. Sc., 62, No. 6, 931-944 (2019).

S. Chattopadhyay, T. A. Hatton, and G. C. Rutledge, “Aerosol filtration using electrospun cellulose acetate fibers,” J. Mater. Sci., 51, No. 1, 204-217 (2016).

J. Xue, T. Wu, et al., “Electrospinning and electrospun nanofibers: Methods, materials, and applications,” Chem. Rev., 119, No. 8, 5298-5415 (2019).

V. I. Kazyuta and A. S. Sosonkin, “Wear life of filtration sleeves during the industrial operation of fabric filters,” Steel Transl., 50, No. 1, 65-75 (2020).

I. O. Tsybuk and A. A. Lysenko, “Influence of fiber length on mechanical properties of paper based on heat resistant and fire-resistant polymer fibers,” Fibre Chem., 51, No. 3, 195-198 (2019).

B. P. Makarov, M. V. Shablygin, et al., “A method for producing nonwoven fabric based on arselon fiber for filtration of air mixtures,” Fibre Chem., 51, No. 6, 437-439 (2020).

P. D. Dubrovski and M. Brezocnik, “Porosity and nonwoven fabric vertical wicking rate,” Fiber. Polym., 17, No. 5, 801-808 (2016).

A. G. Makarov, N. V. Pereborova, et al., “Spectral analysis of viscoelastic creep of nonwoven geotextiles,” Fibre Chem., 50, No. 4, 378-382 (2018).

A. E. Scheidegger, Physics of Flow through Porous Media [in Russian], Institut Komp’yuternykh Issledovanii, Izhevsk (2008).

P. V. Moskalev and V. V. Shitov, Mathematical Modelling of Porous Structures [in Russian], Fizmatlit, Moscow (2007).

S. V. Belov, Porous Metals in Mechanical Engineering [in Russian], Mashinostroenie, Moscow (1976).

A. G. Evdokimov, A. V. Dedov, and V. G. Nazarov, “Air permeability of multilayer needle punched nonwoven fabrics,” Fibre Chem., 50, No. 5, 457-461 (2019).

This research was financially supported by the Ministry of Science and Higher Education of the Russian Federation. State task “Structure and properties of polymer materials obtained using a system of methods of chemically, thermally and/or mechanically induced surface and volumetric modification,” No. FZRR-2020-0024, mnemonic code 0699-2020-0024.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskie Volokna, No. 2, pp. 84-88, March-April, 2021.

Rights and permissions

About this article

Cite this article

Nazarov, V.G., Dedov, A.V. Influence of the Processing Mode of Nonwoven Needle-Punched Materials on Air Filtration. Fibre Chem 53, 143–148 (2021). https://doi.org/10.1007/s10692-021-10255-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10692-021-10255-5