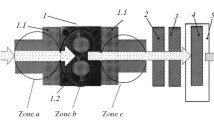

Problems solved by the present author in the course of creating dosing pumps for the production of aramid fibers by a combined dry and wet method are considered. Introduction of a new design of the pump with parts produced from composite materials with polymer matrices and austenitic stainless steels formed by means of a new high-tech method of treatment has made it possible not only to increase the life of the pumps to one year and more, but to also increase the quality of aramid fibers and threads in the course of fabrication.

Similar content being viewed by others

References

D. D. Min’kov, V. Yu. Lakunin, et al., Khim. Volokna, No. 1, 21-23 (2006).

D. G. Tufanov, Corrosion Resistance of Stainless Steels, Alloys, and Pure Metals. Handbook, 4th ed., rev., enlarged [in Russian], Metallurgiya, Moscow (1982), 352 pp.

E. A. Ul’yanin, Corrosion-Resistant Steels and Alloys [in Russian], Metallurgiya, Moscow (1991), 256 pp.

N. D. Tomashov and G. P. Chernova, Theory of Corrosion and Corrosion-Resistant Alloys [in Russian], Metallurgiya, Moscow (1986), 359 pp.

D. V. Min’kov and O. M. Bashkirov, Patent RU 2451836 (Russian Federation), IPC F04C2/08, Gear pump, NPP Orion VDM, No. 2011116969/06, Claim issued April 9, 2011, Byul. No. 15 (May 27, 2012).

D. V. Min’kov, Patent RU 2451837 (Russian Federation), IPC F04C2/08, A method of treating the parts of a gear pump, NPP Orion VDM, No. 2011116971/06, Claim issued April, 9, 2011, Byul. No. 15 (May 27, 2012).

D. V. Min’kov, O. M. Bashkirov, et al., Certain questions related to increasing the service life of friction subassemblies of the equipment of enterprises that produce new chemical fibers, in: Tribology – Machine Construction: Proc. Scientific and Technical Conf. with Participation of Foreign Specialists Devoted to 70th Anniversary of Institute of Machine Science, Russian Academy of Sciences, October 1-2, 2008.

D. V. Min’kov, E. B. Sedin, et al., Reducing the porosity and roughness of the surfaces of the parts of pumps-proportioners by means of polishing with ultra-disperse diamond suspensions, in: Resource-Conserving Technologies of Repair, Restoration, and Hardening of the Parts of Machines, Mechanisms, Equipment, Instruments, and Technological Devices from the Nano- to the Macro-Level: Proc. 12th Intern. Scientific and Practical Conf., April 13-16, 2010, Izd. Politekh. Un-ta, St. Petersburg (2009), Part 2, pp. 225-228.

D. V. Min’kov, O. M. Bashkirov, et al., Use of ultra-disperse diamonds to increase the resistance of austenitic steels to hydrogen wear, in: Nanotechnologies - 2010: Proc. Scientific and Technical Conf. and Youth School and Seminar, Sept. 19 -24, 2010, Taganrog (2010), Part 1, pp. 161-163.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskie Volokna, No. 6, pp. 95–100, November–December, 2018.

Rights and permissions

About this article

Cite this article

Min’kov, D.V. Certain Scientific and Technological Problems That May Be Solved in the Course of Creating Gear Dosing Pumps for the Production of Aramid Fibers. Fibre Chem 50, 578–583 (2019). https://doi.org/10.1007/s10692-019-10034-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10692-019-10034-3