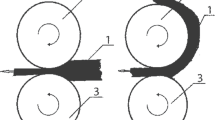

Formation of isolated porosity in impregnated needle-punch material and the degree of impregnation are determined by the fibre composition. When thin fibres are used, closed pores are formed, and coarse fibres cause the formation of communicating porosity. The impregnation of needle-punch material is uneven, and the thickness of the impregnated layer is a function of the weight of the dry latex residue.

Similar content being viewed by others

References

L. A. Sukhareva and Yu. B. Kipnis, Protective Polymer Coatings in Production of Man-Made Leathers [in Russian], Khimiya, Moscow (1989).

P. V. Moskalev and V. V. Shitov, Mathematical Modeling of Pore Structures [in Russian], Fizmatlit, Moscow (2007).

Author information

Authors and Affiliations

Additional information

Translated from Khimicheskie Volokna, No. 1, pp. 34-36, January-February, 2010.

Rights and permissions

About this article

Cite this article

Dedov, A.V. Porosity of impregnated needle-punch material of varying composition. Fibre Chem 42, 38–40 (2010). https://doi.org/10.1007/s10692-010-9220-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10692-010-9220-0