Abstract

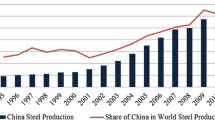

China's crude steel output has grown rapidly since 1990, accounting for more than half of worldwide production in 2019. Iron and steel industry (ISI) in China's energy consumption and carbon emissions accounted for a higher proportion. In the context of China's "carbon peak, carbon neutrality", the ISI attaches great importance to energy conservation and emission reduction. The BF-BOF long process is far from meeting the China’s policy needs in terms of energy-saving and emission-reducing targets. Therefore, the short process of EAF based on scrap steel’s recycling and direct reduced iron (DRI)’s production has attracted great attention. The e-p approach and scenarios analysis method were used to research the impact of scrap steel's recycling and DRI's production on energy demand and carbon emissions of China's ISI. By 2050, scenario 4 (30% DRI based on coal gasification–gas plus 70% scrap steel for EAF) will have the lowest energy consumption (1.79 × 1011 kgce) and scenario 3 (30% DRI based on hydrogen plus 70% scrap steel for EAF) will have the lowest carbon emissions (3.42 × 1011 kg). The results show that the short process of EAF based on scrap steel recycling and DRI is an extremely important approach for the sustainable development of China's ISI in the future.

Similar content being viewed by others

References

Al-Qahtani, A., Parkinson, B., Hellgardt, K., Shah, N., & Guillen-Gosalbez, G. (2021). Uncovering the true cost of hydrogen production routes using life cycle monetisation. Applied Energy, 281, 115958. https://doi.org/10.1016/j.apenergy.2020.115958

An, R. Y., Yu, B. Y., Li, R., & Wei, Y. M. (2018). Potential of energy savings and CO2 emission reduction in China’s iron and steel industry. Applied Energy, 226, 862–880. https://doi.org/10.1016/j.apenergy.2018.06.044

Bachner, G., Mayer, J., Steininger, K. W., Anger-Kraavi, A., Smith, A., & Barker, T. S. (2020). Uncertainties in macroeconomic assessments of low-carbon transition pathways - the case of the European iron and steel industry. Ecological Economics, 172, 106631. https://doi.org/10.1016/j.ecolecon.2020.106631

Bhaskar, A., Assadi, M., & Somehsaraei, H. N. (2020). Decarbonization of the iron and steel industry with direct reduction of iron ore with green hydrogen. Energies, 13(3), 758. https://doi.org/10.3390/en13030758

Editorial Board of China Iron and Steel Industry Yearbook, 1991–2020. China Iron and Steel Industry Yearbook 1991–2020. Beijing: China Iron and Steel Industry Yearbook Press.

Council, Hydrogen. (2020). Path to hydrogen competitiveness. Norway: A cost perspective. Oslo.

Dai, Y. G., & Wang, W. Z. (1994). Converter’s energy consumption and raising of scrap return ratio. Journal of Northeastern University (natural Science), 15(4), 384–389.

Editorial Board of China Energy Yearbook, 1991–2020. China Energy Yearbook 1991–2020. Beijing: China Statistics Press.

Gielen, D. Hydrogen: A Renewable Energy Perspective. 2020.

Griffin, P. W., & Hammond, G. P. (2019). Industrial energy use and carbon emissions reduction in the iron and steel sector: a UK perspective. Applied Energy, 249, 109–125. https://doi.org/10.1016/j.apenergy.2019.04.148

Guan, Y., Wang, J., Yi, W., & Chen, J. (2017). Progress in application of large-scale PSA technology for hydrogen production from coal. Natural Gas Chemical Industry, 42(6), 129–132.

Guo, H. J., & Li, L. (2015). Future of process and equipment on non-coking coal ironmaking (1)—prospect study on process and equipment for smelting reduction. Metallurgical Equipment, 1, 1–11.

Hu, A. G. (2021). China’s goal of achieving carbon peak by 2030 and its main approaches. Journal of Beijing University Technology (Social Sciences Edition), 21(3), 1–15.

Huang D. H., Liu M. S., Zhou L. S., Deng H., Zhang X., Tang B., Tan J. Q. Feasibility practice of reducing production cost of synthetic cast iron by electric furnace melting. 2018 Chongqing Foundry Annual Conference Proceedings, 2018, 4.

International Energy Agency. The future of hydrogen. Paris. 2019.

Jäger-Waldau, A., Kougias, I., Taylor, N., & Thiel, C. (2020). How photovoltaics can contribute to GHG emission reductions of 55% in the EU by 2030. Renewable and Sustainable Energy Reviews, 126, 109836. https://doi.org/10.1016/j.rser.2020.109836

Kannah, R., Kavitha, S., Karthikeyan, O., Kumar, G., Dai-Viet, N., & Banu, J. (2021). Techno-economic assessment of various hydrogen production methods-a review. Bioresource Technology, 319, 124175. https://doi.org/10.1016/j.biortech.2020.124175

Kothari, R., Buddhi, D., & Sawhney, R. (2008). Comparison of environmental and economic aspects of various hydrogen production methods. Renewable and Sustainable Energy Reviews, 12(2), 553–563. https://doi.org/10.1016/j.rser.2006.07.012

Kushnir, D., Hansen, T., Vogl, V., & Åhman, M. (2020). Adopting hydrogen direct reduction for the Swedish steel industry: a technological innovation system (TIS) study. Journal of Cleaner Production, 242, 118185. https://doi.org/10.1016/j.jclepro.2019.118185

Li B. Fundamental study on the smelting high-purity iron and high-purity bearing steel using direct reduced iron prepared by hydrogen. University of Science and Technology Beijing, 2020.

Li, Z. F. (2010). Analysis on cost competitiveness of EAF steel. Metallurgical Economy and Management, 4, 18–21.

Li, Z. L., Dai, H. C., Song, J. N., Sun, L., Geng, Y., Lu, K. Y., & Hanaoka, T. (2019). Assessment of the carbon emissions reduction potential of China’s iron and steel industry based on a simulation analysis. Energy, 183, 279–290. https://doi.org/10.1016/j.energy.2019.06.099

Lin, B. Q., & Wu, R. X. (2020). Designing energy policy based on dynamic change in energy and carbon dioxide emission performance of China’s iron and steel industry. Journal of Cleaner Production, 256, 120412. https://doi.org/10.1016/j.jclepro.2020.120412

Liu Q. Y., Zhang G. J., Wang K., Xia L. L. Research progress in electric furnace steelmaking short process with scrap as raw material. The Chinese Society for Metals: Metallurgy of Hebei Province, 2016, 4

Liu, Y. X., Li, H. J., An, H. Z., Guan, J. H., Liu, N., Han, X. D., Li, C., & Shi, J. L. (2021). Dynamic coupling of the resource-economic-environment systems of China’s steel industrial chain on scrap steel recycling. Resources Science, 43(3), 588–600.

Lu Z. W., Du T., Yue Q. Crossing “Environmental Mountain”—Study on Industrial Ecology. Science Press, 2008: 259–283.

Lu, Z. W., Du, T., Yue, Q., Wang, H. M., & Gao, C. K. (2020). Research on resource consumption and waste discharge in basic materials industry. Beijing: Science Press.

Mele, M., & Magazzino, C. (2020). A Machine Learning analysis of the relationship among iron and steel industries, air pollution, and economic growth in China. Journal of Cleaner Production, 277, 123293. https://doi.org/10.1016/j.jclepro.2020.123293

Ministry of Industry and Information Technology. (2016). Adjustment and upgrading plan of iron and steel industry (2016–2020). China Steel, 12, 5–13.

Parkinson, B., Balcombe, P., Speirs, J., Hawkes, A., & Hellgardt, K. (2019). Levelized cost of CO2 mitigation from hydrogen production routes. Energy & Environmental Science, 12(1), 19–40. https://doi.org/10.1039/c8ee02079e

National Energy Information Platform. Find out what are "carbon peak" and "carbon neutrality"?. https://baijiahao.baidu.com/s?id=1686688366349332643&wfr=spider&for=pc.[accessed 2021–01–11].

Schuler, F., Voigt, N., Schmidt, T., Dahlmann, P., Lüngen, H., & Ghenda, J. (2013). Steel’s contribution to a low-carbon Europe 2050. Stahl Undsen, 133(9), 61–63.

Shan, T. W., Song, P. F., Li, Y. W., Hou, J. G., Wang, X. L., & Zhang, D. (2020). Cost analysis of hydrogen from the perspective of the whole industrial chain of production, storage, transportation and refueling. Natural Gas Chemical Industry, 45(1), 85-90–96.

Shen, W., & Yang, W. Y. (2020). Cost of hydrogen production from fossil energy and electrolyzed water considering carbon emissions. Gas & Heat, 40(3), 30-33–43.

Song, Z., Li, X. S., & Zha, C. H. (2020). Development status and trend of direct reduced iron process in China. China Steel Focus, 16, 22–24.

Tang, J., Chu, M. S., Li, F., Feng, C., Liu, Z. G., & Zhou, Y. S. (2020). Development and progress on hydrogen metallurgy. International Journal of Minerals, Metallurgy and Materials, 27(6), 713–723. https://doi.org/10.1007/s12613-020-2021-4

Tang, J., Chu, M. S., Li, F., Zhou, Y. S., Wang, J. X., Li, S. K., & Liu, Z. G. (2020). Development status and future trend of hydrogen metallurgy in China. Hebei Metallurgy., 8(1–6), 51.

Wang, C., & Zhang, Y. X. (2020). Implementation pathway and policy system of carbon neutrality vision. Chinese Journal of Environmental Management, 12(6), 58–64.

Wang, J. L., Zhao, J. W., Li, G., & Guo, J. (2020a). Economic study on hydrogen production of unconverted oil from residue hydrocracking unit. Petroleum Refinery Engineering, 50(1), 57–59.

Wang, X. E., Luan, T. Y., Chen, Y. Z., & Duan, H. Y. (2016). Research on the evaluation pattern and method of the energy conservation and emission reduction effects of waste resources recycling based on life cycle assessment: a case study of an iron and steel industry enterprise in Jilin Province. China Population, Resources and Environment, 26(10), 69–77.

Wang, Y. H., Wen, Z. G., Yao, J. G., & Dinga, C. D. (2020b). Multi-objective optimization of synergic energy conservation and CO2 emission reduction in China’s iron and steel industry under uncertainty. Renewable and Sustainable Energy Reviews, 134, 110128. https://doi.org/10.1016/j.rser.2020.110128

Wen, Z. G., Meng, F. X., & Chen, M. (2014). Estimates of the potential for energy conservation and CO2 emissions mitigation based on Asian-Pacific Integrated Model (AIM): the case of the iron and steel industry in China. Journal of Cleaner Production, 65, 120–130. https://doi.org/10.1016/j.jclepro.2013.09.008

Wen, Z. G., Wang, Y. H., Li, H. F., Tao, Y., & Clercq, D. D. (2019). Quantitative analysis of the precise energy conservation and emission reduction path in China’s iron and steel industry. Journal of Environmental Management, 246, 717–729. https://doi.org/10.1016/j.jenvman.2019.06.024

World steel statistics 1990-2020. https://www.worldsteel.org/zh/steel-by-topic/statistics/steel-statistical-yearbook.html. [accessed 2020-08-15].

World Steel Association. Energy use in the steel industry. Brussels: World Steel Association, 2019.

Wu, F., & Xie, W. X. (2019). Energy consumption scenario analysis of China’s steel industry under low carbon constraints. Modern Chemical Industry, 39(1), 12–17.

Xuan, Y. N., & Yue, Q. (2017). Scenario analysis on resource and environmental benefits of imported steel scrap for China’s steel industry. Resources, Conservation and Recycling, 120, 186–198. https://doi.org/10.1016/j.resconrec.2016.12.011

Yao, C. L., Zhu, H. C., Jiang, Z. H., Pan, T., Zhang, R., Wang, G. R., & Luo, C. Y. (2020). CO2 emissions calculation and analysis of electric arc furnace with continuous feeding of only scrap. Journal of Materials and Metallurgy, 19(4), 259–264.

Zhao F. Research on Iron In-use Stocks in China and Its Effect on Energy Consumption of Iron and Steel Industry. Northeastern University, 2021.

Zhao, F., Yue, Q., He, J. H., Li, Y., & Wang, H. M. (2020). Quantifying China’s iron in-use stock and its driving factors analysis. Journal of Environmental Management, 274, 111220. https://doi.org/10.1016/j.jenvman.2020.111220

Zhou, Y. S., Qian, H., Zhang, Y. P., & Feng, H. T. (2009). Development direction and strategy of non-blast furnace ironmaking technology. World Iron & Steel, 9(1), 1–8.

Zhu, R., & Tian, B. H. (2019). Cost analysis and cost reduction of EAF steel. Henan Metallurgy, 27(3), 1–7.

Acknowledgements

This research was supported by the National Natural Science Foundation of China (52170177), the National Key Research & Development Program of China (2019YFC1905204) and the Fundamental Research Funds for the Central Universities of China (N182502045).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yue, Q., Chai, X., Zhang, Y. et al. Analysis of iron and steel production paths on the energy demand and carbon emission in China’s iron and steel industry. Environ Dev Sustain 25, 4065–4085 (2023). https://doi.org/10.1007/s10668-022-02234-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10668-022-02234-5