Abstract

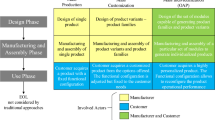

The circular economy is applied in product design to address resource scarcity problems. Prior studies on circular economy associated with product design show a lag of interest in quantifying and assessing the product circularity score, which can support the product designer to identify the improvement opportunities. To address the gap, this study attempts to develop a circular function deployment method using 23 circularity metrics to compute product circularity score and identification of improvement opportunities. An empirical study by choosing a toothbrush as the case product is conducted to evaluate the effectiveness and practical applicability of the proposed method. The assessment of the current design shows that circularity metrics such as upgradability and adaptability, disassembly and reassembly, longevity, and biological cycle have to be addressed to improve the product circularity score. The design expert team’s knowledge has been utilized to develop a new design for toothbrush by addressing the critical metrics, which results in an incremental improvement to product circularity score for essential components from 0.583 to 1.136 without affecting the product functionality. The findings motivate the practitioners to explore the circular economy concepts in their product design to establish their market competitiveness.

Similar content being viewed by others

References

Bakker, C., Wang, F., Huisman, J., & Den Hollander, M. (2014). Products that go round: Exploring product life extension through design. Journal of Cleaner Production, 69, 10–16.

Battini, D., Faccio, M., Persona, A., & Sgarbossa, F. (2011). New methodological framework to improve productivity and ergonomics in assembly system design. International Journal of Industrial Ergonomics, 41(1), 30–42.

Bertanza, G., Canato, M., & Laera, G. (2018). Towards energy self-sufficiency and integral material recovery in waste water treatment plants: Assessment of upgrading options. Journal of Cleaner Production, 170, 1206–1218.

Bertoni, M. (2019). Multi-criteria decision making for sustainability and value assessment in early PSS design. Sustainability, 11(7), 1952.

Blinova, Y., & Potapov, V. (2018). Gas burners used for combustion of biomass-generated gas and gas-like waste. In: Journal of Physics: Conference Series (Vol. 1111, No. 1, p. 012032), IOP Publishing.

Blomsma, F., & Brennan, G. (2017). The emergence of circular economy: A new framing around prolonging resource productivity. Journal of Industrial Ecology, 21(3), 603–614.

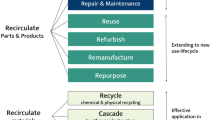

Blomsma, F., & Tennant, M. (2020). Circular economy: Preserving materials or products? Introducing the Resource States framework. Resources, Conservation and Recycling 156: 104698.

Bocken, N. M., De Pauw, I., Bakker, C., & van der Grinten, B. (2016). Product design and business model strategies for a circular economy. Journal of Industrial and Production Engineering, 33(5), 308–320.

Borchardt, M., Wendt, M. H., Pereira, G. M., & Sellitto, M. A. (2011). Redesign of a component based on ecodesign practices: Environmental impact and cost reduction achievements. Journal of Cleaner Production, 19(1), 49–57.

Bovea, M., & Pérez-Belis, V. (2012). A taxonomy of ecodesign tools for integrating environmental requirements into the product design process. Journal of Cleaner Production, 20(1), 61–71.

Bravo, M., & De Brito, J. (2012). Concrete made with used tyre aggregate: Durability-related performance. Journal of Cleaner Production, 25, 42–50.

Bressanelli, G., Perona, M., & Saccani, N. (2019). Challenges in supply chain redesign for the Circular Economy: A literature review and a multiple case study. International Journal of Production Research, 57(23), 7395–7422.

Corona, B., Shen, L., Reike, D., Carreón, J. R., & Worrell, E. (2019). Towards sustainable development through the circular economy—A review and critical assessment on current circularity metrics. Resources, Conservation and Recycling 151: 104498.

Fargnoli, M., Costantino, F., Di Gravio, G., & Tronci, M. (2018). Product service-systems implementation: A customized framework to enhance sustainability and customer satisfaction. Journal of Cleaner Production, 188, 387–401.

Fargonli, M., & Sakao, T. (2017). Uncovering differences and similarities among quality function deployment-based methods in Design for X: Benchmarking in different domains. Quality Engineering, 29(4), 690–712.

Gao, C., Song, K., & Fang, K. (2020). Pathways towards regional circular economy evaluated using material flow analysis and system dynamics. Resources, Conservation and Recycling 154: 104527.

Geda, M. W., Kwong, C. K., & Jiang, H. (2019). Fastening method selection with simultaneous consideration of product assembly and disassembly from a remanufacturing perspective. The International Journal of Advanced Manufacturing Technology, 101(5–8), 1481–1493.

George, D. A., Lin, B. C. A., & Chen, Y. (2015). A circular economy model of economic growth. Environmental Modelling & Software, 73, 60–63.

Hagejärd, S., Ollár, A., Femenías, P., & Rahe, U. (2020). Designing for circularity—Addressing product design, consumption practices and resource flows in domestic kitchens. Sustainability, 12(3), 1006.

Haines-Gadd, M., Chapman, J., Lloyd, P., Mason, J., & Aliakseyeu, D. (2018). Emotional durability design nine—A tool for product longevity. Sustainability, 10(6), 1948.

Halog, A., Schultmann, F., and Rentz, O. (2001). Using quality function deployment for technique selection for optimum environmental performance improvement. Journal of Cleaner Production.

Heikkurinen, P., Young, C. W., & Morgan, E. (2019). Business for sustainable change: Extending eco-efficiency and eco-sufficiency strategies to consumers. Journal of Cleaner Production, 218, 656–664.

Hollander Den, M. C., Bakker, C. A., & Hultink, E. J. (2017). Product design in a circular economy: Development of a typology of key concepts and terms. Journal of Industrial Ecology 21(3): 517–525.

Ishikawa, T., Xie, P., & Kurita, N. (2015). Topology optimization of rotor structure in permanent magnet synchronous motors considering ease of manufacturing. IEEJ Journal of Industry Applications, 4(4), 469–475.

Jayakrishna, K., Vinodh, S., Sanghvi, V. S., & Deepika, C. (2016). Application of GRA for sustainable material selection and evaluation using LCA. Journal of The Institution of Engineers (India): Series C 97(3): 309–322.

Kausch, M. F., & Klosterhaus, S. (2016). Response to ‘Are Cradle to Cradle certified products environmentally preferable? Analysis from an LCA approach.’ Journal of Cleaner Production, 113, 715–716.

Kirchherr, J., Reike, D., & Hekkert, M. (2017). Conceptualizing the circular economy: An analysis of 114 definitions. Resources, Conservation and Recycling, 127, 221–232.

Kjaer, L. L., Pigosso, D. C., Niero, M., Bech, N. M., & McAloone, T. C. (2019). Product/service-systems for a circular economy: The route to decoupling economic growth from resource consumption? Journal of Industrial Ecology, 23(1), 22–35.

Kristensen, H. S., & Mosgaard, M. A. (2020). A review of micro level indicators for a circular economy–moving away from the three dimensions of sustainability?. Journal of Cleaner Production 243: 118531.

Kumar, A., & Dixit, G. (2019). A novel hybrid MCDM framework for WEEE recycling partner evaluation on the basis of green competencies. Journal of Cleaner Production 241: 118017.

Lin, B. C. A. (2020). Sustainable growth: A circular economy perspective. Journal of Economic Issues, 54(2), 465–471.

Loh, Y. R., Sujan, D., Rahman, M. E., & Das, C. A. (2013). Sugarcane bagasse—The future composite material: A literature review. Resources, Conservation and Recycling, 75, 14–22.

Mendoza, J. M. F., Sharmina, M., Gallego-Schmid, A., Heyes, G., & Azapagic, A. (2017). Integrating backcasting and eco-design for the circular economy: The BECE framework. Journal of Industrial Ecology, 21(3), 526–544.

Mitchell, S. L., & Clark, M. (2019). Reconceptualising product life-cycle theory as stakeholder engagement with non-profit organisations. Journal of Marketing Management, 35(1–2), 13–39.

Molino, A., Chianese, S., & Musmarra, D. (2016). Biomass gasification technology: The state of the art overview. Journal of Energy Chemistry, 25(1), 10–25.

Nascimento, D. L. M., Alencastro, V., Quelhas, O. L. G., Caiado, R. G. G., Garza-Reyes, J. A., Rocha-Lona, L., & Tortorella, G. (2019). Exploring Industry 4.0 technologies to enable circular economy practices in a manufacturing context. Journal of Manufacturing Technology Management.

Ng, Y. G., Bahri, M. T. S., Syah, M. Y. I., Mori, I., & Hashim, Z. (2013). Ergonomics observation: Harvesting tasks at oil palm plantation. Journal of Occupational Health 55: 405–414.

Ng, K. S., & Hernandez, E. M. (2016). A systematic framework for energetic, environmental and economic (3E) assessment and design of polygeneration systems. Chemical Engineering Research and Design, 106, 1–25.

Niero, M., Olsen, S. I., & Laurent, A. (2018). Renewable Energy and Carbon Management in the Cradle-to-Cradle Certification: Limitations and Opportunities. Journal of Industrial Ecology, 22(4), 760–772.

Nußholz, J. L. (2018). A circular business model mapping tool for creating value from prolonged product lifetime and closed material loops. Journal of Cleaner Production, 197, 185–194.

Ordoñez, I., & Rahe, U. (2013). Collaboration between design and waste management: Can it help close the material loop? Resources, Conservation and Recycling, 72, 108–117.

Pan, S. Y., Du, M. A., Huang, I. T., Liu, I. H., Chang, E. E., & Chiang, P. C. (2015). Strategies on implementation of waste-to-energy (WTE) supply chain for circular economy system: A review. Journal of Cleaner Production, 108, 409–421.

Petit, G., Sablayrolles, C., & Yannou-Le Bris, G. (2018). Combining eco-social and environmental indicators to assess the sustainability performance of a food value chain: A case study. Journal of Cleaner Production, 191, 135–143.

Philips Full Annual Report (2019). Chapter 13 Sustainability Statements, (pp. 191–213).

Pieroni, M. P., McAloone, T. C., & Pigosso, D. C. (2019). Business model innovation for circular economy and sustainability: A review of approaches. Journal of Cleaner Production, 215, 198–216.

Polese, F., Vesci, M., Troisi, O., & Grimaldi, M. (2019). Reconceptualizing TQM in service ecosystems: An integrated framework. International Journal of Quality and Service Sciences.

Richa, K., Babbitt, C. W., & Gaustad, G. (2017). Eco-efficiency analysis of a lithium-ion battery waste hierarchy inspired by circular economy. Journal of Industrial Ecology, 21(3), 715–730.

Richard, G. M., Mario, M., Javier, T., & Susana, T. (2011). Optimization of the recovery of plastics for recycling by density media separation cyclones. Resources, Conservation and Recycling, 55(4), 472–482.

Rosa, P., Sassanelli, C., & Terzi, S. (2019). Circular business models versus circular benefits: An assessment in the waste from Electrical and Electronic Equipments sector. Journal of cleaner production.

Rousseau, Sandra. (2020). Millennials’ acceptance of product-service systems: Leasing smartphones in Flanders (Belgium). Journal of Cleaner Production 246: 118992.

Sassanelli, C., Rosa, P., Rocca, R., & Terzi, S. (2019). Circular economy performance assessment methods: A systematic literature review. Journal of Cleaner Production.

Schröder, P., Lemille, A., & Desmond, P. (2020). Making the circular economy work for human development. Resources, Conservation and Recycling, 156: 104686.

Selvefors, A., Rexfelt, O., Renström, S., & Strömberg, H. (2019). Use to use–A user perspective on product circularity. Journal of Cleaner Production, 223, 1014–1028.

Shama, M. S., Vinodh, S., & Jayakrishna, K. (2015). Integrated life cycle assessment and activity based life cycle costing approach for an automotive product. Scientia Iranica, 22, 1179–1188.

Singhal, D., Tripathy, S., & Jena, S. K. (2020). Remanufacturing for the circular economy: Study and evaluation of critical factors. Resources, Conservation and Recycling 156: 104681.

Song, W., & Sakao, T. (2018). An environmentally conscious PSS recommendation method based on users’ vague ratings: A rough multi-criteria approach. Journal of Cleaner Production, 172, 1592–1606.

Stamminger, R., Tecchio, P., Ardente, F., Mathieux, F., & Niestrath, P. (2018). Towards a durability test for washing-machines. Resources, Conservation and Recycling, 131, 206–215.

Subramanian, N., Gunasekaran, A., Wu, L., & Shen, T. (2019). Role of traditional Chinese philosophies and new product development under circular economy in private manufacturing enterprise performance. International Journal of Production Research, 57(23), 7219–7234.

Tam, E., Soulliere, K., & Sawyer-Beaulieu, S. (2019). Managing complex products to support the circular economy. Resources, Conservation and Recycling, 145, 124–125.

Tecchio, P., McAlister, C., Mathieux, F., & Ardente, F. (2017). In search of standards to support circularity in product policies: A systematic approach. Journal of Cleaner Production, 168, 1533–1546.

Theresia, A., & Novi, C. (2014). Designing ergonomic toothbrush, toothbrush refill, and toothbrush cap. In: 7th International Seminar on Industrial Engineering and Management. ISSN: 1978-774X.

Tseng, M. L., Chiu, A. S., Liu, G., & Jantaralolica, T. (2020). Circular economy enables sustainable consumption and production in multi-level supply chain system. Resources, Conservation and Recycling 154: 104601.

Tura, N., Hanski, J., Ahola, T., Ståhle, M., Piiparinen, S., & Valkokari, P. (2019). Unlocking circular business: A framework of barriers and drivers. Journal of Cleaner Production, 212, 90–98.

Vieira, A. S., Weeber, M., & Ghisi, E. (2013). Self-cleaning filtration: A novel concept for rainwater harvesting systems. Resources, Conservation and Recycling, 78, 67–73.

Vinodh, S., & Rathod, G. (2010). Integration of ECQFD and LCA for sustainable product design. Journal of Cleaner Production, 18(8), 833–842.

Vinodh, S., & Jayakrishna, K. (2014). Development of integrated ECQFD, LCA and sustainable analysis model. Journal of Engineering, Design and Technology.

Wang, Y., Mendis, G. P., Peng, S., & Sutherland, J. W. (2019). Component-oriented reassembly in remanufacturing systems: Managing uncertainty and satisfying customer needs. Journal of Manufacturing Science and Engineering 141(2).

Whalen, K. A. (2019). Three circular business models that extend product value and their contribution to resource efficiency. Journal of Cleaner Production, 226, 1128–1137.

Whicher, A., Harris, C., Beverley, K., & Swiatek, P. (2018). Design for circular economy: Developing an action plan for Scotland. Journal of Cleaner Production, 172, 3237–3248.

Xu, Y., Zhang, L., Yeh, C. H., & Liu, Y. (2018). Evaluating WEEE recycling innovation strategies with interacting sustainability-related criteria. Journal of Cleaner Production, 190, 618–629.

Xue, D., Hua, G., Mehrad, V., & Gu, P. (2012). Optimal adaptable design for creating the changeable product based on changeable requirements considering the whole product life-cycle. Journal of Manufacturing Systems, 31(1), 59–68.

Yazdani, M., Hashemkhani Zolfani, S., & Zavadskas, E. K. (2016). New integration of MCDM methods and QFD in the selection of green suppliers. Journal of Business Economics and Management, 17(6), 1097–1113.

Yong, J. Y., Klemeš, J. J., Varbanov, P. S., & Huisingh, D. (2016). Cleaner energy for cleaner production: Modelling, simulation, optimisation and waste management. Journal of Cleaner Production, 111, 1–16.

Zhang, X., Zhang, S., Zhang, L., Xue, J., Sa, R., & Liu, H. (2019). Identification of product’s design characteristics for remanufacturing using failure modes feedback and quality function deployment. Journal of Cleaner Production, 239: 117967.

Zhong, S., & Pearce, J. M. (2018). Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recyclebot and RepRap 3-D printing. Resources, Conservation and Recycling, 128, 48–58.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Vimal, K.E.K., Tseng, ML., Raju, S. et al. Circular function deployment: a novel mathematical model to identify design factors for circular economy. Environ Dev Sustain 24, 9068–9101 (2022). https://doi.org/10.1007/s10668-021-01813-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10668-021-01813-2