Abstract

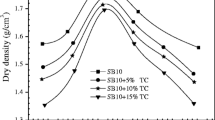

Compacted sand–bentonite mixtures are generally placed at waste dumping places as a means of avoiding contaminant movement to reduce or remove the potential for groundwater pollution. Owing to their almost impermeable nature and high pollutant adsorption tendency, bentonite generally treated as a liner material to avoid subsurface contamination. Cracks are formed in the landfill liner due to the desiccation, large interlayer shrinkage and differential settlement of bentonite. Fibres are commonly added to sand–bentonite mixture to act as a reinforcing material to eliminate the development of tensile cracks. Waste tyre chips are derived from the tyre retreated technique, and it can be included as short fibre in sand–bentonite mixture for the use as landfill barrier material. Hydraulic conductivity and shear strength are the two important parameters of the liner material, which are considered for hydraulic, and stability analysis in landfill application. In this context, consolidation and consolidated undrained tests were performed to study the hydraulic and mechanical behaviour of sand–bentonite mixture mixed in a proportion of 80:20 and mixed with 0, 5, 10 and 15% of waste tyre chips. From the consolidation test, swelling pressure and swelling potential reduced maximal at 15% of tyre chip content. Hydraulic conductivity and negative pore water pressure altered significantly with the application of tyre chips. Effective internal angle of friction enhanced from 24.9° to 30.5° and critical state parameter improved from 0.738 to 1.429 with the presence of 15% of tyre chips. Test result suggested that maximum of 10% of tyre chips can be used as a landfill liner and 15% tyre chips would be benefited for landfill cover.

Similar content being viewed by others

References

Akgün, H., Koçkar, M. K., & Aktürk, Ö. (2006). Evaluation of a compacted bentonite/sand seal for underground waste repository isolation. Environmental Geology, 50(3), 331–337.

Al Wahab, R. M., El-Kedrah, M. A. (1995). Using fibers to reduce tension cracks and shrink/swell in a compacted clay. In Geoenvironment 2000: Characterization, containment, remediation, and performance in environmental geotechnics, ASCE, vol. 46, pp. 791–805.

ASTM D6270. (1998). Standard practice for use of scrap tires in civil engineering applications. West Conshohocken, PA.

ASTM D4318. (2000). Standard test methods for liquid limit, plastic limit, and plasticity index of soils. West Conshohoken, PA.

ASTM D4767. (2000). Standard test methods for consolidated undrained triaxial compression test for cohesive soils. West Conshohocken, PA.

ASTM D422. (2002). Standard test method for particle-size analysis of soils. West Conshohoken, PA.

ASTM D6913. (2009). Standard test methods for particle-size distribution (gradation) of soils using sieve analysis. West Conshohoken, PA.

ASTM D698. (2012). Standard test methods for laboratory compaction characteristics of soil using standard effort. West Conshohoken, PA.

ASTM D854. (2014). Standard test methods for specific gravity of soil solids by water pycnometer. West Conshohocken, PA.

ASTM D2435. (2011). Standard test method for one-dimensional consolidation properties of soils. West Conshohoken, PA.

Benson, C. H., & Othman, M. A. (1993). Hydraulic and mechanical characteristics of a compacted municipal solid waste compost. Waste Management and Research, 11(2), 127–142.

Cetin, H., Fener, M., & Gunaydin, O. (2006). Geotechnical properties of tire-cohesive clayey soil mixtures as a fill material. Engineering Geology, 88(1), 110–120.

Cokca, E., & Yilmaz, Z. (2004). Use of rubber and bentonite added fly ash as a liner material. Waste Management, 24(2), 153–164.

Consoli, N. C., Prietto, P. D., & Ulbrich, L. A. (1998). Influence of fiber and cement addition on behavior of sandy soil. Journal of Geotechnical and Geoenvironmental Engineering, 124(12), 1211–1214.

Cowland, J. W., & Leung, B. N. (1991). A field trial of a bentonite landfill liner. Waste Management and Research, 9(4), 277–291.

Daniel, D. E., & Benson, C. H. (1990). Water content-density criteria for compacted soil liners. Journal of Geotechnical Engineering, 116(12), 1811–1830.

Graham, J., Saadat, F., Gray, M. N., Dixon, D. A., & Zhang, Q. Y. (1989). Strength and volume change behaviour of a sand–bentonite mixture. Canadian Geotechnical Journal, 26(2), 292–305.

Hauser, V. L., Weand, B. L., & Gill, M. D. (2001). Natural covers for landfills and buried waste. Journal of Environmental Engineering, 127(9), 768–775.

Hoornweg, D., and Bhada-Tata, P. (2012). What a waste: A global review of solid waste management, World Bank, Urban Development and Local Government Unit. Washington, DC. http://siteresources.worldbank.org/INTURBANDEVELOPMENT/Resources/336387-1334852610766/What_a_Waste2012_Final.pdf

Kalkan, E. (2013). Preparation of scrap tire rubber fiber-silica fume mixtures for modification of clayey soils. Applied Clay Science, 80–81, 117–125.

Kaneko, T., Orense, R. P., Hyodo, M., & Yoshimoto, N. (2012). Seismic response characteristics of saturated sand deposits mixed with tire chips. Journal of Geotechnical and Geoenvironmental Engineering, 139(4), 633–643.

Khoshand, A., & Fall, M. (2016). Geotechnical characterization of peat-based landfill cover materials. Journal of Rock Mechanics and Geotechnical Engineering, 8(5), 596–604.

Komine, H. (2010). Predicting hydraulic conductivity of sand–bentonite mixture backfill before and after swelling deformation for underground disposal of radioactive wastes. Engineering Geology, 114(3), 123–134.

Lambe, T. W., & Whitman, R. V. (1979). Soil mechanics SI version. London: Wiley.

Maher, M. H., & Ho, Y. C. (1994). Mechanical properties of kaolinite/fiber soil composite. Journal of Geotechnical Engineering, 120(8), 1381–1393.

Marefat, V., & Soltani-Jiagheh, H. (2011). Laboratory behavior of caly-tyre mixture. World Applied Sciences Journal, 13(5), 1035–1041.

Mollins, L. H., Stewart, D. I., & Cousens, T. W. (1999). The drained strength of bentonite enhanced sand. Geotechnique, 49(4), 523–528.

Morris, P. H., Graham, J., & Williams, D. J. (1992). Cracking in drying soils. Canadian Geotechnical Journal, 29(2), 263–277.

Mukherjee, K., & Mishra, A. K. (2017). The impact of scrapped tyre chips on the mechanical properties of liner materials. Environmental Processes, 4(1), 219–233.

Omidi, G. H., Prasad, T. V., Thomas, J. C., & Brown, K. W. (1996). Influence of amendments on the volumetric shrinkage and integrity of compacted clay soils used in landfill liners. Water, Air, Soil and Pollution, 86(1–4), 263–274.

Özkul, Z. H., & Baykal, G. (2006). Shear strength of clay with rubber fiber inclusions. Geosynthetics International, 13(5), 173–180.

Özkul, Z. H., & Baykal, G. (2007). Shear behaviour of compacted rubber fiber-clay composite in drained and undrained loading. Journal of Geotechnical and Geoenvironmental Engineering, 133(7), 767–781.

Quigley, R. M. (1993). Clay minerals against contaminant migration. Geotechnical News, North American Geotechnical Community, 11(4), 44–46.

Ravichandran, P. T., Prasad, A. S., Krishnan, K. D., & Rajkumar, P. R. K. (2016). Effect of addition of waste tyre crumb rubber on weak soil stabilisation. Indian Journal of Science and Technology. https://doi.org/10.17485/ijst/2016/v9i5/87259.

Rayhani, M. H. T., Yanful, E. K., & Fakher, A. (2008). Physical modeling of desiccation cracking in plastic soils. Engineering Geology, 97, 25–31.

Rowe, R. K., Quigley, R. M., & Booker, J. R. (1995). Clayey barrier systems for waste disposal facilities. London: Chapman & Hall.

Sharma, H. D., & Lewis, S. P. (1994). Waste containment systems, waste stabilization, and landfills: design and evaluation. New York: Wiley.

Soltani, A., Taheri, A., Khatibi, M., & Estabragh, A. R. (2017). Swelling potential of a stabilized expansive soil: A comparative experimental Study. Geotechnical and Geological Engineering, 35(4), 1717–1744.

Soltani-Jigheh, H., Asadzadeh, M., & Marefat, V. (2014). Effects of tire chips on shrinkage and cracking characteristics of cohesive soils. Turkish Journal of Engineering and Environmental Sciences, 37(3), 259–271.

Sridharan, A., & Gurtug, Y. (2004). Swelling behaviour of compacted fine grained soils. Engineering Geology, 72(1), 9–18.

Sridharan, A., Rao, A. S., & Sivapullaiah, P. V. (1986). Swelling pressure of clays. ASTM Geotechnical Testing Journal, 9(1), 23–33.

Srivastava, A., Pandey, S., & Rana, J. (2014). Use of shredded tyre waste in improving the geotechnical properties of expansive black cotton soil. Geomechanics and Geoengineering, 9(4), 303–311.

Tajdini, M., Nabizadeh, A., Taherkhani, H., & Zartaj, H. (2017). Effect of added waste rubber on the properties and failure mode of kaolinite clay. International Journal of Civil Engineering, 15(6), 949–958.

Tang, C. S., Shi, B., Liu, C., Suo, W. B., & Gao, L. (2011). Experimental characterization of shrinkage and desiccation cracking in thin clay layer. Applied Clay Science, 52(1), 69–77.

Tansel, B., & Yildiz, B. S. (2011). Goal-based waste management strategy to reduce persistence of contaminants in leachate at municipal solid waste landfills. Environment, Development and Sustainability, 13(5), 821–831.

Taylor, D. W. (1948). Fundamentals of soil mechanics. New York: Wiley.

Terzaghi, K. (1943). Theoretical soil mechanics. New York: Wiley.

Trouzine, H., Bekhiti, M., & Asroun, A. (2012). Effects of scrap tyre rubber fibre on swelling behaviour of two clayey soils in Algeria. Geosynthetics International, 19(2), 124–132.

United States Environmental Protection Agency (US EPA). (1989). RCRA ARARs: Focus on closure requirements, Office of solid waste and emergency response directive 9234.2-04FS, Office of solid waste and emergency response, Washington, DC 20460, USA.

United States Environmental Protection Agency (USEPA). (1988). Design, construction and evaluation on of clay liners for waste management facilities. Technical resource document, hazardous waste engineering research laboratory, Office of research and development, US Environmental protection agency, Cincinnati, Ohio, EPA/530-SW- 86-007F, NTIS PB 86-184496.

Wan, A. W. L., Graham, J., & Gray, M. N. (1990). Influence of soil structure on the stress-strain behavior of sand-bentonite mixtures. Geotechnical Testing Journal, 13(3), 179–187.

Xin, L., He, J., Liu, H., & Shen, Y. (2015). Potential of using cemented soil-tire chips mixture as construction fill, a laboratory study. Journal of Coastal Research, 73(sp1), 564–571.

Yadav, J. S., & Tiwari, S. K. (2016). Effect of inclusion of crumb rubber on the unconfined compressive strength and wet-dry durability of cement stabilized clayey soil. Journal of Building Materials and Structures, 3, 68–84.

Yadav, J. S., & Tiwari, S. K. (2017a). A study on the potential utilization of crumb rubber in cement treated soft clay. Journal of Building Engineering, 9, 177–191.

Yadav, J. S., & Tiwari, S. K. (2017b). Evaluation of the strength characteristics of cement-stabilized clay-crumb rubber mixtures for its sustainable use in geotechnical applications. Environment, Development and Sustainability. https://doi.org/10.1007/s10668-017-9972-2.

Yadav, J. S., & Tiwari, S. K. (2017c). Assessment of geotechnical properties of uncemented/cemented clayey soil incorporated with waste crumb rubber. Journal of Materials and Engineering Structures (JMES), 4(1), 37–50.

Yadav, J. S., & Tiwari, S. K. (2017d). Effect of waste rubber fibres on the geotechnical properties of clay stabilized with cement. Applied Clay Science, 149, 97–110.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mukherjee, K., Mishra, A.K. Hydraulic and mechanical characteristics of compacted sand–bentonite: tyre chips mix for its landfill application. Environ Dev Sustain 21, 1411–1428 (2019). https://doi.org/10.1007/s10668-018-0094-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10668-018-0094-2