Abstract

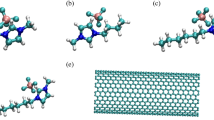

The main purpose of this paper is to evaluate the self-stress state of single-walled Carbon NanoTubes (CNTs) and Flat Graphene Strips (FGSs) in their natural equilibrium state, that is, the state prior to the application of external loads. We model CNTs as discrete elastic structures, whose shape and volume changes are governed by a Reactive Empirical Bond-Order (REBO) interatomic potential of second generation. The kinematical variables we consider are bond lengths, bond angles, and dihedral angles; to changes of each of these variables we associate a work-conjugate nanostress. To determine the self-stress state in a given CNT, we formulate the load-free equilibrium problem as a minimum problem for the interatomic potential, whose solution yields the equilibrium nanostresses; next, by exploiting the nonlinear constitutive dependence we derive for nanostresses in terms of a list of kinematical variables, we determine the equilibrium values of the latter; finally, from the equilibrium values of the kinematical variables we deduce the natural geometry and, in particular, the natural radius.

Our theoretical framework accommodates CNTs of whatever chirality. In the achiral case, the stationarity conditions implied by energy minimization are relatively easy to derive and solve numerically, because we can count on maximal intrinsic symmetries and hence the number of independent unknowns is reduced to a minimum; for chiral CNTs, we prefer to solve the minimum problem directly.

The natural-radius predictions we achieve within our discrete-mechanics framework are in good agreement with the results of calculations based on Density Functional Theory (DFT) and Tight Binding (TB) theory; the same is true for our predictions of the self-energy, that is, the energy associated with self-stress (called cohesive energy in the literature); we surmise that our discrete mechanical model may serve as a source of benchmarks for Molecular-Dynamics (MD) simulation algorithms.

We find that self-stress depends on changes in both bond and dihedral angles in achiral CNTs and, in addition, on changes in bond length in chiral CNTs. Our analysis applies also to FGSs, whose self-stress and self-energy we evaluate; we find that in FGSs self-stress is associated exclusively with changes in bond angle.

Similar content being viewed by others

Notes

While the possibility of obtaining graphene ribbons from CNTs is experimentally proved, there is not yet a conclusive evidence that completely flat graphene sheets can be obtained by unzipping procedures (see, e.g., [51]).

Non-bonded interactions are usually accounted for by including of a Lennard-Jones term in the interatomic potential [47]. Given that the L-J potential is spherical, and that by symmetry all atoms in a CNT are equivalent, the corresponding non-bonded self-stress would be the same as that produced by a small radial force applied on each atom.

The numerical routine we employ is the one available in the software MATLAB (routine fsolve). This routine is a realization of the so-called Trust-Region Method, according to which at each step an approximation of the objective function (namely, the sum of squares of the residues) is minimized over a region whose size is adjusted to improve convergence speed.

Although CNTs are never manufactured by rolling FGSs up, this ideal procedure is sometimes evoked to justify the dependence of the folding energy on \(\rho^{-2}\) and, more generally, to motivate the building of continuum theories for CNTs and FGs. In [36], a non-linear continuum model for graphene is proposed; the bending of an FGS into a cylindrical CNT of given radius is regarded as the outcome of a geometrically defined process and not of an energy minimization; the final rolled-up configuration is assumed to be stressed (although, in principle, energy minimization might have produced an unstressed configuration) and serves as a reference for further mechanical deformations, this time regarded as minimizers of a total energy functional to be found under the constraint that the CNT’s radius stays fixed. In the same spirit, a finite-element model for CNTs was developed in [40], where the self-stress state is computed by means of the classical linear shell theory, on the assumption that the energy stored per unit area because of the roll-up procedure is \(\frac{Et^{3}}{24\rho^{2}(1-\nu^{2})}\), with \(E\) the Young modulus, \(\nu\) the Poisson ratio and \(t\) the wall thickness. If not for other reasons, adopting model equations from the linear theory of thin elastic structures where an evaluation of an elusive quantity like structure thickness is essential seems to us questionable (see [1] and [25] for a discussion about the notion of thickness in continuum models for CNTs).

References

Bajaj, C., Favata, A., Podio-Guidugli, P.: On a nanoscopically-informed shell theory of carbon nanotubes. Eur. J. Mech. A, Solids 42, 137–157 (2013)

Brenner, D.W.: Empirical potential for hydrocarbons for use in simulating the chemical vapor deposition of diamond films. Phys. Rev. B 42(15), 9458 (1990)

Brenner, D.W., Shenderova, O.A., Harrison, J.A., Stuart, S.J., Ni, B., Sinnott, S.B.: A second-generation reactive empirical bond order (REBO) potential energy expression for hydrocarbons. J. Phys. Condens. Matter 14(4), 783 (2002)

Budyka, M.F., Zyubina, T.S., Ryabenko, A.G., Lin, S.H., Mebel, A.M.: Bond lengths and diameters of armchair single wall carbon nanotubes. Chem. Phys. Lett. 407, 266–271 (2005)

Cabria, I., Mintmire, J.W., White, C.T.: Metallic and semiconducting narrow carbon nanotubes. Phys. Rev. B 67, 121406 (2003)

Chang, T.: A molecular based anisotropic shell model for single-walled carbon nanotubes. J. Mech. Phys. Solids 58(9), 1422–1433 (2010)

Chang, T., Gao, H.: Size-dependent elastic properties of a single-walled carbon nanotube via a molecular mechanics model. J. Mech. Phys. Solids 51(6), 1059–1074 (2003)

Chang, T., Geng, J., Guo, X.: Chirality- and size-dependent elastic properties of singlewalled carbon nanotubes. Appl. Phys. Lett. 87, 251–929 (2005)

Chang, T., Geng, J., Guo, X.: Prediction of chirality- and size-dependent elastic properties of single-walled carbon nanotubes via a molecular mechanics model. Proc. R. Soc. A 462, 2523–2540 (2006)

Chen, J.Y., Huang, Y., Ortiz, M.: Fracture analysis of cellular materials: a strain gradient model. J. Mech. Phys. Solids 46(5), 789–828 (1998)

Davini, C.: Homogenization of a graphene sheet. Contin. Mech. Thermodyn. 26(1), 95–113 (2014)

Davini, C., Ongaro, F.: A homogenized model for honeycomb cellular materials. J. Elast. 104(1–2), 205–226 (2011)

Demczyk, B.G., Wang, Y.M., Cumings, J., Hetman, M., Han, W., Zettl, A., Ritchie, R.O.: Direct mechanical measurement of the tensile strength and elastic modulus of multiwalled carbon nanotubes. Mater. Sci. Eng. A, Struct. Mater.: Prop. Microstruct. Process. 334(1–2), 173–178 (2002)

Demichelis, R., Noël, Y., D’Arco, P., Rerat, M., Zicovich-Wilson, C.M., Dovesi, R.: Properties of carbon nanotubes: an ab initio study using large Gaussian basis sets and various DFT functionals. J. Phys. Chem. C 115, 8876–8885 (2011)

Ding, W., Calabri, L., Kohlhaas, K.M., Chen, X., Dikin, D.A., Ruoff, R.S.: Modulus, fracture strength, and brittle vs. plastic response of the outer shell of arc-grown multi-walled carbon nanotubes. Exp. Mech. 47, 25–36 (2007)

Favata, A., Micheletti, A., Podio-Guidugli, P.: A nonlinear theory of prestressed elastic stick-and-spring structures. Int. J. Eng. Sci. 80, 4–20 (2014)

Favata, A., Podio-Guidugli, P.: A shell theory for chiral single-wall carbon nanotubes. Eur. J. Mech. A, Solids 45, 198–210 (2014)

Favata, A., Micheletti, A., Ryu, S., Pugno, N.M.: An analytical benchmark and a Mathematica program for MD codes: testing LAMMPS on the 2nd generation Brenner potential (submitted for publication)

Geng, J., Chang, T.: Nonlinear stick-spiral model for predicting mechanical behavior of single-walled carbon nanotubes. Phys. Rev. B 74, 245428 (2006)

Georgantzinos, S.K., Giannopoulos, G.I., Anifantis, N.K.: Numerical investigation of elastic mechanical properties of graphene structures. Materials & Design 31(10), 4646–4654 (2010)

Georgantzinos, S.K., Giannopoulos, G.I., Katsareas, D.E., Kakavas, P.A., Anifantis, N.K.: Size-dependent non-linear mechanical properties of graphene nanoribbons. Comput. Mater. Sci. 50(7), 2057–2062 (2011)

Giannopoulos, G.I.: Elastic buckling and flexural rigidity of graphene nanoribbons by using a unique translational spring element per interatomic interaction. Comput. Mater. Sci. 1, 388–395 (2012)

Giannopoulos, G.I., Liosatos, I.A., Moukanidis, A.K.: Parametric study of elastic mechanical properties of graphene nanoribbons by a new structural mechanics approach. Physica E 1, 124–134 (2011)

Hernández, E., Goze, C., Bernier, P., Rubio, A.: Elastic properties of C and \({B}_{\mathit{x}}{C}_{\mathit {y}}{N}_{\mathit{z}}\) composite nanotubes. Phys. Rev. Lett. 80, 4502–4505 (1998)

Huang, Y., Wu, J., Hwang, K.C.: Thickness of graphene and single-wall carbon nanotubes. Phys. Rev. B 74, 245413 (2006)

Jiang, H., Zhang, P., Liu, B., Huang, Y., Geubelle, P.H., Gao, H., Hwang, K.C.: The effect of nanotube radius on the constitutive model for carbon nanotubes. Comput. Mater. Sci. 28, 429–442 (2003)

Jindal, V.K., Imtani, A.N.: Bond lengths of armchair single-waled carbon nanotubes and their pressure dependence. Comput. Mater. Sci. 44, 156–162 (2008)

Kanamitsu, K., Saito, S.: Geometries, electronic properties, and energetics of isolated single walled carbon nanotubes. J. Phys. Soc. Jpn. 71, 483–486 (2002)

Kosynkin, D.V., Higginbotham, A.L., Sinitskii, A., Lomeda, J.R., Dimiev, A., Price, B.K., Tour, J.M.: Longitudinal unzipping of carbon nanotubes to form graphene nanoribbons. Nature 458(7240), 872–876 (2009)

Kürti, J., Zólyomi, V., Kertesz, M., Sun, G.: The geometry and the radial breathing mode of carbon nanotubes: beyond the ideal behaviour. New Journal of Physics 5, 21 (2003)

Lee, C., Wei, X., Kysar, J.W., Hone, J.: Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 321(5887), 385–388 (2008)

Lee, R.K.F., Cox, B.J., Hill, J.M.: General rolled-up and polyhedral models for carbon nanotubes. Fuller. Nanotub. Carbon Nanostruct. 19, 726–748 (2011)

Liu, S., Su, W.: Effective couple-stress continuum model of cellular solids and size effects analysis. Int. J. Solids Struct. 46(14–15), 2787–2799 (2009)

Lu, J.P.: Elastic properties of carbon nanotubes and nanoropes. Phys. Rev. Lett. 79, 1297–1300 (1997)

Lu, Q., Arroyo, M., Huang, R.: Elastic bending modulus of monolayer graphene. J. Phys. D 42(10), 102002 (2009)

Lu, Q., Huang, R.: Nonlinear mechanics of single-atomic-layer graphene sheets. Int. J. Appl. Mech. 01(03), 443–467 (2009)

Machón, M., Reich, S., Thomsen, C., Sánchez-Portal, D., Ordejón, P.: Ab initio calculations of the optical properties of 4-Å-diameter single-walled nanotubes. Phys. Rev. B 66, 155410 (2002)

Meo, M., Rossi, M.: Prediction of Young’s modulus of single wall carbon nanotubes by molecular-mechanics based finite element modelling. Compos. Sci. Technol. 66, 1597–1605 (2006)

Merli, R., Lázaro, C., Monleón, S., Domingo, A.: A molecular structural mechanics model applied to the static behavior of single-walled carbon nanotubes: new general formulation. Comput. Struct. 127, 68–87 (2013)

Pantano, A., Parks, D.M., Boyce, M.C.: Mechanics of deformation of single- and multi-wall carbon nanotubes. J. Mech. Phys. Solids 52(4), 789–821 (2004)

Popov, V.N.: Curvature effects on the structural, electronic and optical properties of isolated single-walled carbon nanotubes within a symmetry-adapted non-orthogonal tight-binding model. New J. Phys. 6, 17 (2004)

Pugno, N.M.: The role of defects in the design of space elevator cable: from nanotube to megatube. Acta Mater. 55(15), 5269–5279 (2007)

Pugno, N.M.: Young’s modulus reduction of defective nanotubes. Appl. Phys. Lett. 90, 4 (2007)

Robertson, D.H., Brenner, D.W., Mintmire, J.W.: Energetics of nanoscale graphitic tubules. Phys. Rev. B 45, 12592–12595 (1992)

Sánchez-Portal, D., Artacho, E., Soler, J.M., Rubio, A., Ordejón, P.: Ab initio structural, elastic, and vibrational properties of carbon nanotubes. Phys. Rev. B 59, 12678–12688 (1999)

Shen, L., Li, J.: Transversely isotropic elastic properties of single-walled carbon nanotubes. Phys. Rev. B 69, 045414 (2004)

Stuart, S.J., Tutein, A.B., Harrison, J.A.: A reactive potential for hydrocarbons with intermolecular interactions. J. Chem. Phys. 112, 6472 (2000)

Tersoff, J.: New empirical approach for the structure and energy of covalent systems. Phys. Rev. B 37, 699 (1988)

Tersoff, J.: Modeling solid-state chemistry: interatomic potentials for multicomponent systems. Phys. Rev. B 39, 5566(R) (1989)

Troiani, H.E., Miki-Yoshida, M., Camacho-Bragado, G.A., Marques, M.A.L., Rubio, A., Ascencio, J.A., Jose-Yacaman, M.: Direct observation of the mechanical properties of single-walled carbon nanotubes and their junctions at the atomic level. Nano Lett. B 3(6), 751–755 (2003)

Wang, H., Wang, Y., Hu, Z., Wang, X.: Cutting and unzipping multiwalled carbon nanotubes into curved graphene nanosheets and their enhanced supercapacitor performance. ACS Appl. Mater. Interfaces 4(12), 6827–6834 (2012). PMID: 23148646

Wang, Q.: Effective in-plane stiffness and bending rigidity of armchair and zigzag carbon nanotubes. Int. J. Solids Struct. 42, 5451–5461 (2004)

Xiao, J., Gama, B., Gillespie, J., Jr.: An analytical molecular structural mechanics model for the mechanical properties of carbon nanotubes. Int. J. Solids Struct. 42, 3075–3092 (2005)

Xu, R., Wang, Y., Liu, B., Fang, D.: Mechanics interpretation on the bending stiffness and wrinkled pattern of graphene. J. Appl. Mech. 80, 040910 (2013)

Acknowledgements

A.F. acknowledges the Italian INdAM-GNFM (Istituto Nazionale di Alta Matematica—Gruppo Nazionale di Fisica Matematica), through “Progetto Giovani 2014—Mathematical models for complex nano- and bio-materials”. N.M.P. is supported by the European Research Council (ERC StG Ideas 2011 BIHSNAM no. 279985 on “Bio-Inspired hierarchical super-nanomaterials”, ERC PoC 2015 SILKENE No. 693670 on ‘Bionic silk with graphene or other nanomaterials spun by silkworms’, ERC PoC 2013-2 KNOTOUGH No. 632277 on ‘Super-tough knotted fibers”), by the European Commission under the Graphene Flagship (WP10 “Nanocomposites”, No. 604391) and by the Provincia Autonoma di Trento (“Graphene Nanocomposites”, No. S116/2012-242637 and reg. delib. No. 2266). We all acknowledge interesting discussions with Dr. Seunghwa Ryu about comparing our predictions with those of congruent MD simulations.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix A: Details about the Computation of Dihedral Angles

1.1 A.1 Armchair CNTs

With reference to Fig. 4, and for \(\mathbf {c}_{1},\mathbf {c}_{2},\mathbf {c}_{3}\) the basis vectors of the Cartesian frame there shown, let us introduce the following unit vectors:

In terms of these unit vectors, the cosines of the dihedral angles \(\varTheta_{1}^{A},\varTheta_{2}^{A},\varTheta_{3}^{A}\) read:

Together with (18), these relations, which are equivalent to the first three of (20), permit to compute the first derivatives of \(\beta^{A}\) and \(\varTheta_{i}^{A}\) (\(i=1,2,3\)) with respect to \(\alpha\):

1.2 A.2 Zigzag CNTs

With reference to Fig. 5, we introduce the unit vectors

For the dihedral angles, we find:

a set of relations equivalent to the first, second, and fourth, of (25). With these and (23), we find:

Appendix B: 2nd-Generation REBO Potentials for Hexagonal Lattices

2.1 B.1 General Form

As anticipated in Sect. 2, the 2nd-generation REBO potentials developed for hydrocarbons by Brenner et al. in [3] accommodate up third-nearest-neighbor interactions, through a bond-order function depending also on dihedral angles. In general, given a substance or a group of substances in the hydrocarbon family, the appropriate potential is tailored by fitting the parameters to the available experimental data and ab initio calculations; the behavior of electron clouds is not accounted for explicitly, and quantum effects are ignored. In spite of these limitations, the predictions obtained with the use of REBO potentials, when compared with those obtained by ab initio or TB methods, have been always found accurate qualitatively, and sometimes even quantitatively. In fact, REBO potentials do incorporate much of the physics and chemistry involved in covalent bonding, as well as Coulomb interactions and many-body effects; if necessary, they also can accommodate bond-breaking and bond-formation.

The binding energy \(V\) of an atomic aggregate is written as a sum over nearest neighbors:

the interatomic potential \(V_{\mathit{IJ}}\) is given by the construct

where the individual effects of the repulsion and attraction functions \(V_{R}(r_{\mathit{IJ}})\) and \(V_{A}(r_{\mathit{IJ}})\), which model pair-wise interactions of atoms \(I\) and \(J\) depending on their distance \(r_{\mathit{IJ}}\), are modulated by the bond-order function \(b_{\mathit{IJ}}\). The repulsion and attraction functions have the following forms:

where \(f^{C}(r)\) is a cutoff function limiting the range of covalent interactions, and where \(Q\), \(A\), \(B_{n}\), \(\alpha\), and \(\beta \), are parameters to be chosen fit to a material-specific dataset. The remaining ingredient in (60) is the bond-order function:

where apexes \(\sigma\) and \(\pi\) refer to two types of bonds: the strong covalent \(\sigma\)-bonds between atoms in one and the same given plane, and the \(\pi\)-bonds responsible for interlayer interactions, which are perpendicular to the plane of \(\sigma\)-bonds. We now describe functions \(b_{\mathit{IJ}}^{\sigma-\pi}\) and \(b_{\mathit{IJ}}^{\pi}\).

The role of function \(b_{\mathit{IJ}}^{\sigma-\pi}\) is to account for the local coordination of, and the bond angles relative to, atoms \(I\) and \(J\); its form is:

Here, for each fixed pair of indices \((I,J)\), (a) the cutoff function \(f_{\mathit{IK}}^{C}\) limits the interactions of atom \(I\) to those with its nearest neighbors; (b) \(\lambda_{\mathit{IJK}}\) is a string of parameters designed to prevent attraction in some specific situations; (c) function \(P_{\mathit{IJ}}\) depends on \(N_{I}^{C}\) and \(N_{I}^{H}\), the numbers of \(C\) and \(H\) atoms that are nearest neighbors of atom \(I\); it is meant to adjust the bond-order function according to the environment of the C atoms in one or another molecule; (d) for solid-state carbon, the values of both the string \(\lambda_{\mathit{IJK}}\) and the function \(P_{\mathit{IJ}}\) are taken null; (e) function \(G\) modulates the contribution of each nearest neighbor of atom \(I\) in terms of the cosine of the angle between the \(\mathit{IJ}\) and \(\mathit{IK}\) bonds; its analytic form is given by three sixth-order polynomial splines. Function \(b_{\mathit{IJ}}^{\pi}\) is given a split representation:

where the first addendum \(\varPi_{\mathit{IJ}}^{\mathit{RC}}\) depends on whether the bond between atoms \(I\) and \(J\) has a radical character and on whether it is part of a conjugated system, while the second addendum \(b_{\mathit{IJ}}^{\mathit{DH}}\) depends on dihedral angles and has the following form:

where function \(T_{\mathit{IJ}}\) is a tricubic spline depending on \(N_{I}^{t}=N_{I}^{C}+N_{I}^{H}\), \(N_{J}^{t}\), and \(N_{\mathit{IJ}}^{\mathrm{conj}}\), a function of local conjugation.

2.2 B.2 The Form Used in This Paper

We write here the expressions we use for the functions \(V_{A}\), \(V_{R}\) and \(b_{\mathit{IJ}}\) defined in (61) and (62); we also record the form of their first derivatives, because they enter Eqs. (46) and (51).

The attractive and repulsive part of the potential, and their first derivatives are:

The bond order function \(b_{\mathit{IJ}}\) (62) specializes to \(b_{a}\) and \(b_{b}\), respectively, for \(a\)- and \(b\)-type bonds in achiral CNTs (cf. Eqs. (40)), and it specializes to \(b_{i}\) for the typical bond in chiral CNTs (cf. the second of (50)):

The following derivatives of bond-order functions are found in Eq. (46):

the derivatives found in Eq. (51) are:

(subscripts should be taken modulo 3).

In Eq. (63), the angular-contribution function \(G\) is:

whence

The polynomial coefficients \(d_{ji}\) are computed following [3]; they are reported in the following table:

\(d_{ji}\) | i | ||||||

|---|---|---|---|---|---|---|---|

0 | 1 | 2 | 3 | 4 | 5 | ||

j | 1 | 0.37545 | 1.40678 | 2.25438 | 2.03128 | 1.42971 | 0.50240 |

2 | 0.70728 | 5.67744 | 24.09702 | 57.59183 | 71.88287 | 36.27886 | |

3 | −0.64440 | −6.20800 | −20.05900 | −30.22800 | −21.72400 | −5.99040 | |

The parameters of the binding energy \(V\), the same as in [3, 47], are:

Appendix C: The Traction Problem

We here derive the explicit form of the balance equations for the case when a pure-traction load is applied to an achiral CNT. We made use of the solution to this problem in Sect. 5.2, when we compared the folding energy of CNTs with the energy stored in such a traction problem.

With reference to (6), for \(F\) be the magnitude of the axial traction, the load potential takes the following form:

where \(\delta\widehat{\lambda}(a,b,\alpha)\) is the load-induced change in length of the CNT under study. It follows that the balance equations are:

The mappings \((a,b,\alpha)\mapsto\widehat{\lambda}^{A}(a,b,\alpha)\) and \((a,b,\alpha)\mapsto\widehat{\lambda}^{Z}(a,b,\alpha)\) are here defined with the use of Eqs. (29) and (36)), respectively; hence, we have that:

Equations (81)–(82) can be so specialized as to hold in the case of a FGS subject to a uniform traction load along the armchair or the zigzag direction: it is enough to take \(\varphi=0\) and, consequently, \(\alpha+2\beta=2\pi\), \(\varTheta_{i}=0\), \(i=1,\ldots,4\).

Appendix D: Computational Results

In this Appendix we collect a number of tables summarizing the results of our computations. Numerical values for the natural geometric parameters are shown in Tables 2 and 3. Table 2 also shows: (i) the percent difference of bond lengths \(a\) and \(b\) with respect to \(r_{0}=0.14204\ \mbox{nm}\), the C–C distance in graphene computed according to the potential chosen in this study; (ii) the percent differences between the natural and nominal values of the bond angles \(\alpha\) and \(\beta\) (\(\alpha_{0}\) and \(\beta_{0}\) have been computed by substituting \(\alpha_{0}^{A}=2\pi/3\) in (19), solving for \(\beta_{0}^{A}\) (A case), and by substituting \(\beta_{0}^{Z}=2\pi/3\) in (23), solving for \(\alpha_{0}^{Z}\) (Z case)).

Rights and permissions

About this article

Cite this article

Favata, A., Micheletti, A., Podio-Guidugli, P. et al. Geometry and Self-stress of Single-Wall Carbon Nanotubes and Graphene via a Discrete Model Based on a 2nd-Generation REBO Potential. J Elast 125, 1–37 (2016). https://doi.org/10.1007/s10659-015-9568-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10659-015-9568-8