Abstract

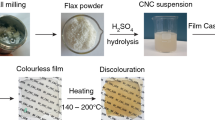

The composite industry urgently needs to develop effective and efficient surface treatment techniques for high-strength plant fibers. A newly designed hybrid approach which combines surface treatment techniques of three categories is studied in this research, in which sodium bicarbonate treatment is conducted to ‘gently’ clean the flax fiber, silane treatment served to add functional group and silane-grafted cellulose nanocrystals (CNCs) are applied to fiber surface to promote fiber-matrix interaction. Three processes are designed in order to combine silane treatment and CNC treatment. In the first process, CNCs were directly deposited on flax fabric after which flax fabric with CNCs was subjected to silane treatment. In the second process, flax fabric was simultaneously subjected to CNC deposition and silane treatment. In the third process, CNCs were separately subjected to silane treatment and later collected using a centrifuge. Later, silane-grafted CNCs were deposited flax fabric. The combined NaHCO3-silane treatment improved the tensile strength of flax/polypropylene composites by 26.6%. It was also confirmed that CNCs could enhance fiber/matrix interface via mechanical interlocking. As the concentration of CNC suspension increased, density of CNCs on fiber surface increased. When the concentration is 5 g/L, optimum performance of flax/polypropylene composites is observed. In terms of moisture absorption, it was found that NaHCO3-silane treatment could reduce moisture absorption (by 49.8%) while CNCs induce higher moisture content (by 31.1% when CNC concentration was 10.0 g/L). More importantly, the results of this study indicated that the moisture absorption and mechanical properties of composites could be largely affected by the nature of the interface. Proper fiber/matrix interface engineering can reduce moisture absorption and enhance mechanical properties.

Similar content being viewed by others

Data availability

Data supporting the findings of this study are available from the corresponding author upon request.

References

Abdelmouleh M, Boufi S, Belgacem MN, Dufresne A (2007) Short natural-fibre reinforced polyethylene and natural rubber composites: effect of silane coupling agents and fibres loading. Compos Sci Technol 67:1627–1639. https://doi.org/10.1016/j.compscitech.2006.07.003

Amiralian N, Annamalai PK, Memmott P, Martin DJ (2015) Isolation of cellulose nanofibrils from Triodia pungens via different mechanical methods. Cellulose 22(4):2483–2498. https://doi.org/10.1007/s10570-015-0688-x

Azimi B, Sepahvand S, Ismaeilimoghadam S, Kargarzadeh H, Ashori A, Jonoobi M, Danti S (2024) Application of Cellulose-Based Materials as Water Purification Filters; A state-of-the-Art Review. J Polym Environ 32:345–366. https://doi.org/10.1007/s10924-023-02989-6

Babaee M, Jonoobi M, Hamzeh Y, Ashori A (2015) Biodegradability and mechanical properties of reinforced starch nanocomposites using cellulose nanofibers. Carbohydr Polym 132:1–8. https://doi.org/10.1016/j.carbpol.2015.06.043

Bachtiar D, Sapuan SM, Hamdan MM (2008) The effect of alkaline treatment on tensile properties of sugar palm fibre reinforced epoxy composites. Mater Des 29:1285–1290. https://doi.org/10.1016/j.matdes.2007.09.006

Bai HL, Wang X, Zhou YT, Zhang LP (2012) Preparation and characterization of poly(vinylidene fluoride) composite membranes blended with nano-crystalline cellulose. Prog Nat Sci-Mater 22:250–257. https://doi.org/10.1016/j.pnsc.2012.04.011

Baley C, Le Duigou A, Bourmaud A, Davies P (2012) Influence of drying on the mechanical behaviour of flax fibres and their unidirectional composites. Compos Part A-Appl S 43:1226–1233. https://doi.org/10.1016/j.compositesa.2012.03.005

Bartolomé JF, Gutierrez-Gonzalez CF, Torrecillas R (2008) Mechanical properties of alumina-zirconia-Nb micro-nano-hybrid composites. Compos Sci Technol 68:1392–1398. https://doi.org/10.1016/j.compscitech.2007.11.010

Blaker JJ, Lee KY, Bismarck A (2011) Hierarchical Composites Made Entirely from Renewable Resources. J Biobased Mater Bio 5:1–16. https://doi.org/10.1166/jbmb.2011.1113

Borchani KE, Carrot C, Jaziri M (2015) Untreated and alkali treated fibers from alfa stem: effect of alkali treatment on structural, morphological and thermal features. Cellulose 22:1577–1589. https://doi.org/10.1007/s10570-0150583-5

Dash BN, Rana AK, Mishra SC, Mishra HK, Nayak SK, Tripathy SS (2000) Novel low-cost jute-polyester composite. II. SEM observation of the fractured surfaces. Polym-Plast Technol 39:333–350. https://doi.org/10.1081/PPT-100100033

Davoodi MM, Sapuan SM, Ahmad D, Ali A, Khalina A, Jonoobi M (2010) Mechanical properties of hybrid kenaf/glass reinforced epoxy composite for passenger car bumper beam. Mater Des 31(10):4927–4932. https://doi.org/10.1016/j.matdes.2010.05.021

Davoodi MM, Sapuan SM, Ahmad D, Ali A, Khalina A, Jonoobi M (2011) Concept selection of car bumper beam with developed hybrid bio-composite material. Mater Des 32(10):4857–4865. https://doi.org/10.1016/j.matdes.2011.06.011

Demirci MT, Tarakçıoğlu N, Avci A, Akdemir A, Demirci I (2017) Fracture toughness (Mode I) characterization of SiO2 nanoparticle filled basalt/epoxy filament wound composite ring with split-disk test method. Compos Part B-Eng 119:114–124. https://doi.org/10.1016/j.compositesb.2017.03.045

Hajlane A, Joffe R, Kaddami H (2018) Cellulose nanocrystal deposition onto regenerated cellulose fibres: Effect on moisture absorption and fibre–matrix adhesion. Cellulose 25:1783–1793. https://doi.org/10.1007/s10570-018-1680-z

Hanan F, Jawaid M, Tahir PM (2020) Mechanical performance of oil palm/kenaf fiber-reinforced epoxy-based bilayer hybrid composites. J Nat Fibers 17:155–167. https://doi.org/10.1080/15440478.2018.1477083

Ilyas RA, Aisyah HA, Nordin A, Ngadi N et al (2022) Natural-fiber-reinforced chitosan, chitosan blends and their nanocomposites for various advanced applications. Polymers 14:874. https://doi.org/10.3390/polym14050874

John MJ, Anandjiwala RD (2008) Recent developments in chemical modification and characterization of natural fiber-reinforced composites. Polym Composite 29:187–207. https://doi.org/10.1002/pc.20461

Jonoobi M, Huran J, Mathew AP, Hussein MZB, Oksman K (2010) Preparation of cellulose nanofibers with hydrophobic surface characteristics. Cellulose 17:299–307. https://doi.org/10.1007/s10570-009-9387-9

Jonoobi M, Mathew AP, Abdi MM, Makinejad MD, Oksman K (2012) A comparison of modified and unmodified cellulose nanofiber reinforced polylactic acid (PLA) prepared by twin screw extrusion. J Polym Environ 20:991–997. https://doi.org/10.1007/s10924-012-0503-9

Joseph PV, Joseph K, Thomas S, Pillai CKS, Prasad VS, Groeninckx G, Sarkissova M (2003) The thermal and crystallisation studies of short sisal fibre reinforced polypropylene composites. Compos Part A-Appl S 34:253–266. https://doi.org/10.1016/S1359-835X(02)00185-9

Kabir MM, Wang H, Lau KT, Cardona F (2012) Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Compos Part B-Eng 43:2883–2892. https://doi.org/10.1016/j.compositesb.2012.04.053

Kargarzadeh H, Ahmad I, Abdullah I, Dufresne A, Zainudin SY, Sheltami RM (2012) Effects of hydrolysis conditions on the morphology, crystallinity, and thermal stability of cellulose nanocrystals extracted from kenaf bast fibers. Cellulose 19(3):855–866. https://doi.org/10.1007/s10570-012-9684-6

Kargarzadeh H, Sheltami RM, Ahmad I, Abdullah I, Dufresne A (2015) Cellulose nanocrystal: A promising toughening agent for unsaturated polyester nanocomposite. Polymer 56:346–357. https://doi.org/10.1016/j.polymer.2014.11.054

Khalil HPSA, Bhat AH, Yusra AFI (2012) Green composites from sustainable cellulose nanofibrils: A review. Carbohydrate Polymers Carbohyd Polym 87:963–979. https://doi.org/10.1016/j.carbpol.2011.08.078

Kinloch AJ, Taylor AC, Techapaitoon M, Teo WS, Sprenger S (2015) Tough, natural-fibre composites based upon epoxy matrices. J Mater Sci 50:6947–6960. https://doi.org/10.1007/s10853-015-9246-z

Kumar V, Kumar R (2012) Dielectric and mechanical properties of alkali-and silane-treated bamboo-epoxy nanocomposites. J Compos Mater 46:3089–3101. https://doi.org/10.1177/0021998311435831

Kumar R, Kumar K, Bhowmik S (2018) Mechanical characterization and quantification of tensile, fracture and viscoelastic characteristics of wood filler reinforced epoxy composite. Wood Sci Technol 52:677–699. https://doi.org/10.1007/s00226-018-0995-0

Kumar S, Falzon B, Kun J, Wilson E, Graninger G, Hawkins SC (2020) High performance multiscale glass fibre epoxy composites integrated with cellulose nanocrystals for advanced structural applications. Compos Pt A-Appl Sci Manuf 131:105801. https://doi.org/10.1016/j.compositesa.2020.105801

Kuyumcu M, Kurtulus C, Ciftci M, Tasdelen MA (2024) Improving the mechanical properties of fiber-reinforced polymer composites through nanocellulose-modified epoxy matrix. Express Polym Lett 18(1):61–71. https://doi.org/10.3144/expresspolymlett.2024.5

Latif R, Wakeel S, Khan NZ, Siddiquee AN, Verma SL, Khan ZA (2019) Surface treatments of plant fibers and their effects on mechanical properties of fiber-reinforced composites: A review. J Reinf Plast Comp 38:15–30. https://doi.org/10.1177/0731684418802022

Lee KY, Aitomäki Y, Berglund LA, Oksman K, Bismarck A (2014) On the use of nanocellulose as reinforcement in polymer matrix composites. Compos Sci Technol 105:15–27. https://doi.org/10.1016/j.compscitech.2014.08.032

Lee CH, Khalina A, Nurazzi NM, Norli A, Harussani MM, Rafiqah SA, Aisyah HA, Ramli N (2021) The Challenges and Future Perspective of Woven Kenaf Reinforcement in Thermoset Polymer Composites in Malaysia: A Review. Polymers 13(9):1390. https://doi.org/10.3390/polym13091390

Lessan F, Karimi M, Bañuelos JL, Foudazi R (2020) Phase separation and performance of polyethersulfone/cellulose nanocrystals membranes. Polymer 186:121969. https://doi.org/10.1016/j.polymer.2019.121969

Li X, Tabil LG, Panigrahi S (2007) Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A review. J Polym Environ 15:25–33. https://doi.org/10.1007/s10924-006-0042-3

Lin N, Huang J, Dufresne A (2012) Preparation, properties and applications of polysaccharide nanocrystals in advanced functional nanomaterials: A review. Nanoscale 4:3274–3294. https://doi.org/10.1039/c2nr30260h

Ling Z, Edwards JV, Guo ZW, Prevost NT, Nam S, Wu QL, French AD, Xu F (2019) Structural variations of cotton cellulose nanocrystals from deep eutectic solvent treatment: micro and nano scale. Cellulose 26(2):861–876. https://doi.org/10.1007/s10570-018-2092-9

López-Buendía AM, Romero-Sánchez MD, Climent V, Guillem C (2013) Surface treated polypropylene (PP) fibres for reinforced concrete. Cement Concrete Res 54:29–35. https://doi.org/10.1016/j.cemconres.2013.08.004

Matinlinna JP, Lung CYK, Tsoi JKH (2018) Silane adhesion mechanism in dental applications and surface treatments: A review. Dent Mater 34:13–28. https://doi.org/10.1016/j.dental.2017.09.002

Nicu R, Ciolacu F, Ciolacu DE (2021) Advanced Functional Materials Based on Nanocellulose for Pharmaceutical/Medical Applications. Pharmaceutics 13:1125. https://doi.org/10.3390/pharmaceutics13081125

Peng XW, Zhong LX, Ren JL, Sun RC (2010) Laccase and alkali treatments of cellulose fibre: Surface lignin and its influences on fibre surface properties and interfacial behaviour of sisal fibre/phenolic resin composites. Compos Part A-Appl S 41:1848–1856. https://doi.org/10.1016/j.compositesa.2010.09.004

Prasob PA, Sasikumar M (2018) Static and dynamic behavior of jute/epoxy composites with ZnO and TiO2 fillers at different temperature conditions. Polym Test 69:52–62. https://doi.org/10.1016/j.polymertesting.2018.04.040

Saddique A, Kim JC, Bae J, Cheong IW (2024) Low-temperature, ultra-fast, and recyclable self-healing nanocomposites reinforced with non-solvent silylated modified cellulose nanocrystals. Int J Bilo Macromol 254:127984. https://doi.org/10.1016/j.ijbiomac.2023.127984

Salas C, Nypelö T, Rodriguez-Abreu C, Carrillo C, Rojas OJ (2014) Nanocellulose properties and applications in colloids and interfaces. Curr Opin Colloid in 19:383–396. https://doi.org/10.1016/j.cocis.2014.10.003

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-Ray diffractometer. Text Res J 29(10):786–794. https://doi.org/10.1177/004051755902901003

Sepe R, Bollino F, Boccarusso L, Caputo F (2018) Influence of chemical treatments on mechanical properties of hemp fiber reinforced composites. Compos Part B-Eng 133:210–217. https://doi.org/10.1016/j.compositesb.2017.09.030

Sun Y, Xu AC, Chen CJ, Luo C, Bao LM (2022) Effect of alkali and silane treatments on properties of green composites based on ramie fibers and cellulose acetate resin. Bioresources 17:2390–2402. https://doi.org/10.15376/biores.17.2.2390-2402

Wambua P, Ivens J, Verpoest I (2003) Natural fibres: Can they replace glass in fibre reinforced plastics? Compos Sci Technol 63:1259–1264. https://doi.org/10.1016/S0266-3538(03)00096-4

Xiao X, Zhong YC, Cheng MY, Sheng L, Wang D, Li SX (2021) Improved hygrothermal durability of flax/polypropylene composites after chemical treatments through a hybrid approach. Cellulose 28:11209–11229. https://doi.org/10.1007/s10570-021-04179-w

Yan LB, Chouw N, Jayaraman K (2014) Flax fibre and its composites - A review. Compos Part B-Eng 56:296–317. https://doi.org/10.1016/j.compositesb.2013.08.014

Yue YY, Zhou CJ, French AD, Xia G, Han GP, Wang QW, Wu QL (2012) Comparative properties of cellulose nano-crystals from native and mercerized cotton fibers. Cellulose 19(4):1173–1187. https://doi.org/10.1007/s10570-012-9714-4

Zakaria S, Poh LK (2002) Polystyrene-benzoylated EFB reinforced composites. Polym-Plast Technol 41:951–962. https://doi.org/10.1081/PPT-120014397

Zhao F, Tian P, Li Y, Weng Y, Zeng J (2023) Fabrication of well-dispersed cellulose nanocrystal reinforced biobased epoxy composites using reversibility of covalent adaptable network. Int J Biol Macromol 244:125202. https://doi.org/10.1016/j.ijbiomac.2023.125202

Živković I, Fragassa C, Pavlovic A, Brugo T (2017) Influence of moisture absorption on the impact properties of flax, basalt and hybrid flax/basalt fiber reinforced green composites. Compos Part B-Eng 148:148–164. https://doi.org/10.1016/j.compositesb.2016.12.018

Funding

This work is sponsored by the National Natural Science Foundation of China (Grant No. 12202325). This research work is also supported by the Open Project Program of Ministry of Education Key Laboratory for Advanced Textile Composite Materials (Tiangong University), No. MATC-2021–006.

Author information

Authors and Affiliations

Contributions

C.L. and T.L. prepared the images, drafted the work and did the experiments. Y.Z. made substantial contributions to the conceptions, design of the work, interpretation of data and funding acquisition. Y.Z. also drafted the work and revised it critically for important intellectual content. W.L. and Z.Z. were involved in the interpretation of data and writing for the paper. S.L., L.J. and C.W. provided resources. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Ethical Approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Luo, C., Lin, T., Zhong, Y. et al. Effects of cellulose nanocrystal-based hybrid modification on flax/polypropylene composites. Cellulose (2024). https://doi.org/10.1007/s10570-024-05907-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10570-024-05907-8